Research

Highlights...

|

|

| Number 130 |

April 14, 2003 |

|

Diatomite dilemma: Getting at the oil

|

|

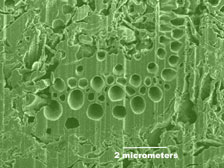

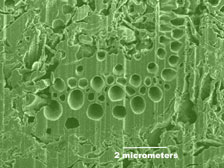

Nanoscale

image of diatomite

|

Consisting of silica skeletons of microscopic aquatic plants, oil-bearing

diatomite is fragile—up to 70 percent empty space—but

nearly impermeable. Using ion-beam milling and imaging, Liviu

Tomutsa of the Earth Sciences Division and Velimir Radmilovic

of the National Center for Electron Microscopy at Lawrence

Berkeley National Laboratory have made nanoscale images of

diatomite. "As the beam shaves off layers of material a few nanometers

thick, it simultaneously makes a stack of 2-D images," says Tomutsa.

From these they will build a 3-D picture that reveals the constrictions

and connectivity of the pores, factors that affect trapping of

liquids.

[Paul Preuss, 510/486-6249,

paul_preuss@lbl.gov]

|

|

What chemicals are

in our air?

DOE's Pacific Northwest National Laboratory

has created a Chemical Testing Chamber to identify harmful chemicals

in the air as well as test the performance of sensors used to

detect weapons of mass destruction. The chamber includes a powerful

new gas chromatograph-mass spectrometer, which can be used to

identify concentrations of any one of thousands of organic chemicals.

The facility is different from other chemical testing chambers

in that it gives scientists the capability to work with the very

low concentrations of semi-volatile chemicals. Semi-volatile chemicals

are used to produce pesticides and herbicides, but also can be

used in chemical weapons made by terrorists. The chamber is undergoing

final performance testing and will be ready for research use later

this spring.

[Ginny

Sliman, 509/375-4372,

Virginia.sliman@pnl.gov]

|

|

Agriculture for the

future

A team of Idaho National Engineering

and Environmental Laboratory and Oak

Ridge National Laboratory scientists are conducting discussions

with agricultural interests to create an R&D roadmap. The roadmap

aims to produce feedstock

for future biomass refineries. Through new agribusiness, a sustainable

supply of biomass would be available to produce clean fuels and

chemicals from corn and wheat stalks and the substance that cements

cell walls together. The goal of this DOE Office of Biomass

project is to move the U.S. towards energy independence, and

guide the allocation of limited funds to national labs and universities

that can make the project successful. Discussions are being held

in Washington, D.C., Chicago, Minneapolis, Boise and Oklahoma City.

[Reuel

Smith, 208/526-3733,

mrs@inel.gov]

|

|

X-rays produce fossil

images in stereo

|

|

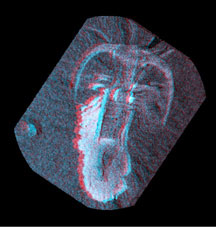

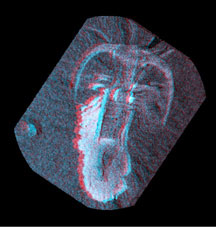

650-million-year-old

Marella splendens fossil

|

Scientists at DOE's Los Alamos

National Laboratory, working with researchers from Conoco-Phillips,

have demonstrated the ability to generate elemental X-ray images

using micro X-ray fluorescence. The team recently obtained stereoview

elemental images of a 650-million-year-old Marella splendens

fossil from the Burgess shale in Canada (see accompanying image).

Researchers exposed the fossil-bearing rock to an X-ray beam and

captured the resulting fluorescence, or X-ray emission, in the

form of spectral lines, to image the fossil. The stereoview image

shows dimensional elemental features that cannot be seen by eye.

The process will be useful to a wide array of other difficult

material analyses.

[Todd

Hanson, 505/665-2085,

tahanson@lanl.gov]

|

|

JGI marks genomics

milestones

The role of DOE's Office of Science

in genomics research is being highlighted this month as two of the

most important landmarks in the history of biological research are

celebrated: the completion this year of the human genome sequence,

and James Watson and Francis Crick's Nobel Prize-winning description

of the DNA double helix 50 years ago. The DOE Joint

Genome Institute (JGI) in Walnut Creek, California, played a

key role in the Human Genome Project

by sequencing chromosomes 5, 16 and 19. The JGI is a consortium

formed by Lawrence Berkeley, Lawrence

Livermore, and Los Alamos

national laboratories.

[Charles

A. Osolin, 925/296-5643,

osolin1@llnl.gov]

|

|

Fighting

radiological terrorism

with knowledge

|

|

Brian

Rees

|

Across the United States, medical and hospital professionals

are learning about the effects of nuclear exposure and radiation

dispersal devices (RDDs) thanks to the on-camera skills of Los

Alamos health physicist Brian Rees.

Radiological Terrorism for Healthcare is an educational

video made to inform health professionals of the reasonable

precautions that are effective in treating those exposed to

RDDs and other sources of nuclear contamination.

|

|

Radiological

Terrorism

for Healthcare

|

The Tucson, AZ-based Medfilms

company that produced the tape contacted DOE's Los

Alamos National Laboratory in 2002 to see if anyone there

could talk about the effects of an RDD, in the logical, down-to-earth

terms that would be helpful to nurses and other emergency workers.

Rees, already providing similar, live briefings as part of his

work with the Laboratory's Health, Safety, and Radiation Protection

Division, was an easy choice.

"Medical personnel cover a wide gamut of the population in

general, and many of them have the same misconceptions about

radiation that the general population has," says Rees. "I wanted

to be sure their misconceptions didn't end up harming anybody,

either by their actions or inactions.

" With that in mind, Rees and the Medfilms director,

Alan Reeter, developed a video that shows, through the example

of a 1987 radiation-exposure incident in Goiania, Brazil, what

health-care workers can expect in a radiological accident or

deliberate exposure situation. Among the key effects is panic,

which brought over 100,000 people to hospital doorways in Goiania,

despite the fact that just over one percent of that number actually

required hospitalization—still a significant number, four

of whom died, but nowhere near as large as the surging crowd

that sought treatment and reassurance.

The video, already available to hospitals for several months

now, recently won a "Chris" award from the Columbus International

Film and Video Festival in Columbus, Ohio, in the Physical Health

category.

Submitted by DOE's Los

Alamos National Laboratory

|

|