- Number 376 |

- November 19, 2012

'Strain tuning' reveals promise in nanoscale manufacturing

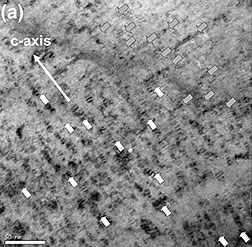

Semicontinuous barium zirconium oxide

nanodots or nanorods aligned parallel to

both the c-axis and the ab-planes of the

superconducting film.

Researchers at DOE's Oak Ridge National Laboratory have reported progress in fabricating advanced materials at the nanoscale. The spontaneous self-assembly of nanostructures composed of multiple elements paves the way toward materials that could improve a range of energy efficient technologies and data storage devices.

ORNL researchers combined theoretical and experimental studies to understand and control the self-assembly of insulating barium zirconium oxide nanodots and nanorods within barium-copper-oxide superconducting films.

"We found that a strain field that develops around the embedded nanodots and nanorods is a key driving force in the self-assembly," said Amit Goyal, a UT-Battelle Corporate Fellow. "By tuning the strain field, the nanodefects self-assembled within the superconducting film and included defects aligned in both vertical and horizontal directions."

The strain-tuning the team demonstrated has implications in the nanoscale fabrication of controlled, self-assembled nanostructures of multiple elements, with properties suitable for a range of electrical and electronic applications, including multiferroics, magnetoelectrics, thermoelectrics, photovoltaics, ultra-high density information storage and high-temperature superconductors.[Bill Cabage, 865.574.4399,

cabagewh@ornl.gov]