- Number 417 |

- July 7, 2014

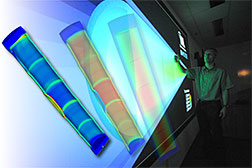

BISON helps researchers create complex nuclear fuel simulations

The BISON modeling code provides insight

into processes researchers would not

otherwise have resources to simulate on

their own.

It's rare that a chipped nuclear fuel pellet makes its way into a reactor. However, if one of the millions of pencil-sized pellets does have a small defect, it can affect the fuel's performance. Exactly how these effects evolve is just one of the situations BISON can simulate in an effort to help engineers enhance nuclear fuel safety margins.

BISON is a computer code developed at DOE's Idaho National Laboratory, and it is one of a herd of applications — most also named after animals — that utilizes the Multiphysics Object Oriented Simulation Environment (MOOSE) framework, also developed at INL.

The BISON code enables engineers to troubleshoot new ideas before building prototypes or experimental tests, making it easier to gain insight into complex processes. By refining designs based on simulation data, scientists can maximize the efficiency of time and resources dedicated to testing in research reactors.

BISON can create 3-D simulations for a variety of fuel types, including those used in commercial nuclear reactor power plants, plate-type fuel used in some university and research reactors, metallic-type fuel, and TRISO particle fuel used in Very High Temperature Gas Reactors. The modeling program can simulate numerous factors that impact fuel development, including complicated physical phenomena such as thermal expansion, solid and gaseous fission product swelling, densification, thermal and irradiation creep, and thermal and mechanical contact.

"It's very complex software to solve very hard problems," says BISON lead Richard Williamson, who has been developing the software since 2009.

As a multiphysics simulation program, BISON can model events like temperature changes, the thermal expansion of the fuel and the stresses in the fuel cladding. These three properties are linked: fission produces heat, which causes the temperature to rise and the fuel to expand, which in turn stresses the cladding. To simulate each physical development, BISON uses fully-coupled equations, which interact with each other in the same rapid-fire way as the physics they describe.

When used in tandem with other MOOSE capabilities, BISON’s multiscale capabilities allow researchers to see what’s going on at an atomistic level, as well as larger scales ranging from micrometers to meters. Engineers can understand what happens inside a reactor in a matter of seconds, or they can watch the behavior of simulated fuel over the course of years.

"We're working on state-of-the-art codes that run simulations very few others can," says nuclear engineer Danielle Perez. "It's exciting."

Researchers around the world are using BISON's unique capabilities. Forty-five labs, companies and universities use MOOSE or its applications (including BISON) to research nuclear fuel, reactor safety, geothermal systems and many other fields of study. And that number grows monthly.

Now, the BISON team is working on refining the software and validating simulation results by comparing them with physical experimental results. Is BISON reaching the correct conclusions about what's happening inside a reactor?

So far, after comparing BISON to several experiments, the answer is yes.Submitted by DOE’s Idaho National Laboratory