- Number 439 |

- May 18, 2015

Inventing extra protection for high energy waste

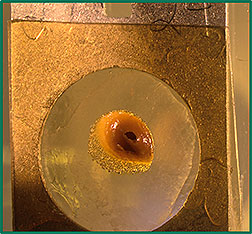

Prototype of improved radiological

containment bag.

At DOE's Savannah River National Laboratory, the primary goal is innovation for safe and cost effective legacy waste cleanup. New methods are constantly being explored in order to protect workers and protect the environment. When Senior Scientist Dr. Aaron Washington realized that a radiological waste bag wasn’t lasting as long as he would like, he set about inventing a new one. As a result, Washington and his team of researchers created a “double-ply” waste containment bag capable of better containing nuclear waste.

Much like a household garbage bag is used to protect waste from leaking into a garbage can, special radiological waste bags are used to keep radiation from leaking into a storage container. After time, materials used to create these bags fail due to damage from intense or long-term exposure to radiation. This can result in contamination and a need to repackage the contents. This new invention uses nanotechnology to infuse radiation-resistant particles onto a sacrificial polymer layer. By altering the material on a molecular level, it is now able to virtually eliminate damage from high-energy alpha particles. Savannah River National Laboratory is in the process of patenting this technology.

“It can be thought of as adding an additional layer of containment. This inner polymer layer is highly resistant to radiation damage compared to the polyethylene alone and will extend the life of the bag by an order of magnitude without much additional cost,” explained Washington. The improved containment bag will be vital in the cleanup and containment of high-energy waste such as plutonium.

This technology will save money, but more importantly, it will make the process safer. Alpha radiation generating waste with long-term storage often needs to be repackaged before it can be delivered for final disposal. “If we eliminate or significantly reduce this need for repackaging, we will save time, reduce the risk of personnel exposure, and reduce the environmental impact of generating more waste with failed contaminated bags. Additionally, by using inexpensive polymers and additives, the cost increase associated with making the improved bag is minimal,” Washington said.

The special coating includes materials that may also be used as a sensor because the materials change color if the inner layer of the bag is breached. The research team is continuing to evaluate this coating for application to other plastics and surfaces.

Other members of the research team include SRNL Principal Engineer Mike Serrato, Senior Engineer Dr. Jason Wilson, Senior Scientist Dr. Joseph Teprovich, and Postdoctoral Researcher Dr. Jonathan Christian.[Lana Cox, 803.725.4396,

Lana.cox@srnl.doe.gov]