|

Number 96, January-February 2008 |

Peering inside the puzzle

Peering inside the puzzle

New microscopy techniques could unlock the mysteries of ferroelectric materials

|

|

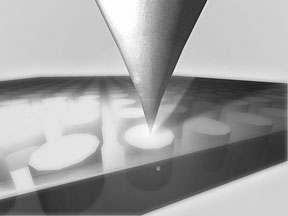

A scanning probe microcope writes data on a ferroelectric thin film. Each cylinder represents a bit of information that is “up or down” in polarization. A piezoresponse force microscope probe can read and write information as well as analyze the material and information storing processes. |

ORNL’s work on piezoresponse force microscopy is providing a powerful analytical tool for the electronics industry as it determines the best design strategies for future generations of ferroelectric nonvolatile memory and data storage devices.

A paper recently published in the Proceedings of the National Academy of Sciences describes a quantitative piezoresponse force microscopy, or PFM, study on electric polarization switching in multiferroic materials in a nearly defect-free environment.

Lead author Sergei Kalinin of the Center for Nanophase Materials Sciences and Materials S&T Division explains that ferroelectric materials are among the prospective candidates for next-generation data storage and nonvolatile memory devices, which retain their information after power is removed.

“Currently, nearly all data the Information Age comprises are stored as up and down magnetic polarization bits in ferromagnetic materials. But we are rapidly approaching the fundamental physical constraints that limit the information density on these media. In ferroelectric materials, data are stored as bits of electrical polarization and can achieve much higher storage densities, potentially approaching molecular and atomic levels,” Sergei says.

Ferroelectric technology could provide a path around “the wall” that currently faces the Moore’s Law axiom that computer chip power will double every two years. One advantage of FE is that it doesn’t generate as much damaging heat.

“It is impossible to predict which materials will form the basis of next-generation data storage and memory technologies. However, a key element in any future technology is the capability to study the information writing and readout on the nanometer scale of a realistic device element, or a single bit in recording medium,” Sergei says from his office in the Center for Nanophase Materials Sciences, DOE’s nanoscience center at ORNL.

The advantages offered by ferroelectrics as compared with standard silicon semiconductor technology include nonvolatility and very high storage densities. Although the idea for ferroelectric data storage isn’t new—patents on the concept go back nearly a half-century and FE memory technology can be found in cell phones and computer games—fabrication difficulties have ruled it out for more advanced applications such as nanoscale devices.

“All information is physical and embodied in matter. Whether it is cuneiform scratches in ancient clay tablets or polarization states in ferroelectric crystals, the qualities of materials ultimately determine the quantity and volatility of the information stored,” says coauthor Stephen Jesse. “Understanding materials at the nanoscale tells us how we can best record and retrieve data on that scale.”

Polarization switching in macroscopic devices is controlled by defects that are unavoidable in large volumes of material, which is a “crucial aspect,” Sergei says.

|

|

Ferroelectric technology could provide a path around “the wall” that currently faces the Moore’s Law axiom that computer chip power will double every two years. |

“For nanoscale applications, we need to study the properties of materials with few or no defects. By using an SPM [scanning probe microscope] probe, we can find an essentially defect-free region and study the mechanism of formation of a single 10-nanometer bit, directly probing how information will be stored on a ferroelectric hard drive or within a memory cell,” he says.

Using an ultrasharp metallic tip, PFM focuses an electric field within extremely small volumes of material, thus limiting the number of defects within the active region. This approach offers researchers a way to characterize material properties on a very small scale.

Coauthors on the PNAS paper with Sergei include ORNL’s Brian Rodriguez and Stephen Jesse, along with R. Ramesh of the University of California-Berkeley, Long Qing Chen of Pennsylvania State University and Anna Morozovska of the Ukrainian Academy of Sciences.

“ORNL has always had a strong position in materials synthesis. With the new analytical tools and methods coming on-line at CNMS and MST, the Laboratory acquires a rapidly emerging strength in materials characterization—on the level of several nanometers, a molecule or an atom – where the real action happens,” Sergei says.—B.C. ![]()

Agreement puts superconducting cable closer to grid

Agreement puts superconducting cable closer to grid

|

|

The Fusion Energy Division’s Christopher Rey examines a trough with high-temperature superconducting cable immersed in a liquid-nitrogen test environment. |

The licensing agreement that ORNL and a Schenectady, N.Y., company signed on January 9 could be offered up as a textbook example of a federal research laboratory and private company partnership that brings advanced technology from the laboratory to the marketplace.

The pact that Lab Director Thom Mason signed with SuperPower, Inc.’s Venkat Selvamanickam represents a key technical solution to the growing problem of the country’s strained and outdated electrical grid.

“This brings us one step closer to commercialization and to grid modernization,” said Selvamanickam, SuperPower’s vice president and chief technical officer.

SuperPower is in the business of making superconducting wire for power delivery and other applications. High temperature superconductors—high temperature in the sense that the material is superconducting at the relatively warm temperature of liquid nitrogen—conduct electricity with no resistance.

Power transmission and distribution systems, or the power grid, lose a significant fraction of power during electricity delivery. Superconducting technology is seen as a way to move more power more efficiently over existing rights-of-way.

That’s important, because as much as people need more power on the grid, it’s increasingly difficult to build more grid, which we see as the transmission towers and lines that cross our increasingly valuable landscapes.

High capacity superconducting power lines—which move electricity with extreme efficiency in a small footprint—represent one answer. The problem is that superconducting materials are notoriously difficult to work with. For instance, the brittle superconductor material needs to be deposited onto a metal template to make it flexible.

“These are terrible materials to work with,” noted Thom Mason at the signing. “It’s like taking a charcoal bricquet and turning it into a wire. And processing the material can disrupt its superconducting properties.”

SuperPower came to ORNL to help solve the seemingly insurmountable difficulties in forming a long length of uniformly high performance, high-temperature superconducting, or HTS, wire at high throughputs. The HTS material is a ceramic that is deposited on a near-single-crystal quality metallic base template; single-crystal-like texture provides high current capacity whereas the metal template provides flexibility. But simply depositing the HTS material on the template affects the superconducting properties, so researchers had to come up with a buffer material.

The buffer posed another dilemma in that the template’s texture property is key to being able to correctly deposit the HTS material. Not only does the buffer need to mimic the single-crystal-like texture of the template, but it also needs to be able to transfer the texture to the superconductor and be chemically compatible with the superconductor. In addition, all of these characteristics must be achieved at high rates using the specific deposition process selected by the manufacturer.

Some years ago a team of ORNL researchers under the sponsorship of DOE’s Office of Science performed fundamental studies on the epitaxial formation of films. With this enhanced understanding and the support of DOE’s Office of Electricity Delivery and Energy Reliability, the researchers discovered a number of high-quality epitaxial buffer materials with various attributes. Among these is the lanthanum-manganese-oxide (LMO) buffer material that made the SuperPower buffer-deposition process commercially feasible.

“It offered a high-throughput process, meaning it could be made fast, and also provided a wider processing window so that minor fluctuations didn’t spoil the wire,” says Dominic Lee, who manages the Lab’s Superconductivity program. “That was the solution that has enabled SuperPower to produce the world’s longest-length second-generation high-temperature superconducting wire with world record performance.”

The wire, which looks more like a tape, has been stranded into cable and is actually in the field. A 30-meter cable made up of 10,000 meters of the wire has been installed at a substation in Albany, N.Y., making it the world’s first on-the-grid second-generation wire-based HTS device.

A superconducting cable can carry three to five times more current than a like-sized cable of copper, one of the best conventional conductors of electricity. HTS wire alone, without the secondary material needed for a cable, can carry 150 times more current.

Dominic says substations and other congested areas—where it is difficult to add capacity by constructing new facilities and acquiring new rights-of-way—are the most likely near-term applications of HTS power equipment.

Another application SuperPower is pursuing is in fault-current limiters. These HTS devices can staunch fault currents, the runaway current spikes that might otherwise travel down the grid, damaging equipment and causing outages.

SuperPower’s relationship with ORNL ranges back to a cooperative R&D agreement in 2002. The pact has been extended to 2010.

The ORNL-SuperPower collaboration won a 2007 R&D100 Award and 2007 Federal Laboratory Consortium Southeast Region Excellence in Technology Transfer Award. Members of the Lab’s High-Performance LMO-enabled, High Temperature Superconducting Wires team include Parans Paranthaman and Tolga Aytug of the Chemical Sciences Division and Amit Goyal of MSTD.

On hand for the January 9 signing were Thom, Selvamanickam, DOE Principal Deputy Assistant Secretary for Electricity Delivery and Energy Reliability Patricia A. Hoffman and ORNL Partnerships Director Tom Ballard.—B.C. ![]()

|

|

Signing the SuperPower agreement are (from left) SuperPower’s “Selva” Selvamanickam, ORNL Partnerships Director Tom Ballard, DOE Principal Deputy Assistant Secretary for Electricity Delivery and Energy Reliability Patricia A. Hoffman and ORNL Director Thom Mason. |

Tom Ballard leads

retitled Partnerships

Tom Ballard leads

retitled Partnerships

Tom Ballard has been named director of ORNL’s Partnerships Directorate, formerly known as Technology Transfer and Economic Development.

Tom joined the management team of UT-Battelle in July 2004 and served as ORNL’s Director of Economic Development and Partnerships. He had been interim director of TTED since August.

The Partnerships Directorate will continue to house the program functions of intellectual property management, licensing, sponsored research, and economic development while adding two new areas: educational partnerships and industrial development. ![]()

ORNL, Jackson State

begin collaboration

ORNL, Jackson State

begin collaboration

ORNL and Jackson State University have

launched a joint initiative that will help expand the university’s research programs and promote research collaboration at both institutions.

The initiative, signed January 23, is the second mentor protégé agreement between a DOE lab and a historically black college or university.

ORNL Director Thom Mason said the partnership gives the lab opportunities to gain access to new expertise; extend research capabilities; and identify exceptional candidates for positions at ORNL.

The agreement will help provide new ORNL opportunities in fields where Jackson State University’s capabilities are nationally known, such as chemistry, environmental science and human health. ![]()

|

Good New Year on Chestnut Ridge

Good New Year on Chestnut Ridge

It’s been a fruitful year so far for the Spallation Neutron Source.

We’re beginning to learn that when an e-mail comes from Chestnut Ridge with a “Woo-hoo!” in it, something good has

happened.

For instance, a fifth instrument, the Spallation Neutrons and Presssure beamline, received neutrons for the first time. The SNAP Diffractometer is used to study materials under extreme conditions, proving particularly useful to studies in the earth and geological sciences.

Also, during January’s run the proton beam power was increased to just over 300 kilowatts, nearly doubling last summer’s high-water mark. Every increase is a new beam-on-target record, and calculations on neutron production are putting that superlative beyond all doubt.

Finally, the SNS has charted its first published article. Physical Review Letters has accepted an article, titled “ pH-induced release of polyanions from multilayer films.” The work was co-authored by Liquids Reflectometer lead researcher John Ankner and collaborators from New Jersey’s Stevens Institute of Technology. It concerns studies on coatings with potential uses that include biosensors, drug delivery systems, antifogging or antireflection surfaces.

Aviators are gone; lighthouse remains

Aviators are gone; lighthouse remains

|

|

This structure supported the airway lighthouse beacons that once showed the way for the nation’s pioneer airmail pilots. |

Back in the days of Lucky Lindy, pilots navigating their airplanes across the landscape at night were aided by beacons situated throughout the countryside. A system of airway lighthouse beacons was erected in the 1920s to light the way for the Transcontinental Air Mail Route.

The structures housed a diesel generator that powered the light perched on an adjoining tower.

The lighthouses were made obsolete by radio technology after World War II, and most of them are gone without a trace. There is a surviving relic, however, on the Oak Ridge Reservation.

The structure, located on Chestnut Ridge, is pretty much just a dilapidated, although sturdily built, shack. Charles Tichy, a historic architect employed by the Environmental Protection & Waste Management Division, says although the equipment is long gone, there are signs of its once important mission, such as a black band painted around the building and concrete pads that supported the beacon.

“This building and site are considered potentially eligible for listing on the National Register of Historic Places. It represents an early system for night navigation for U.S. airmail. Though the unit does not retain its equipment, the survival of the structure and concrete piers is sufficient to convey this story,” Tichy writes.

The lighthouse, which is well off the beaten path, was recently uncovered during clearing for a new power transmission line. Its only task now is to serve as a reminder of the earliest days of aviation.

JIHIR marks 25 and growing

JIHIR marks 25 and growing

|

|

Building 6008’s new “theory wing” will be adjacent to the joint institute’s auditorium. |

After 25 years, the Joint Institute for Heavy Ion Research is adding on. Organizers for a meeting of the Japan-U.S. Theory Institute for Physics with Exotic Nuclei took some time on January 23 to mark the joint institute’s 25th anniversary.

JIHIR was the brainchild of a group of physicists, including University of Tennessee professor (and former ORNL deputy director) Lee Riedinger, UT’s Carroll Bingham and Vanderbilt University’s Joe Hamilton, to establish a means to open the Lab’s Holifield Facility and its tools such as the Recoil Mass Spectrometer to university users, back in 1982.

The idea of getting the state and state universities to collaborate with a federal research lab was novel at the time. Hamilton remarked that it was “no easy matter” to convince the Atomic Energy Commission—the federal agency at the time—to go along, but the proposal team “shot down every objection.”

Years later, UT-Battelle used the JIHIR as a model for the four much larger joint institutes in computional, biological, neutron and materials sciences. In a quarter-decade of success the JIHIR has hosted 1,200 researchers.

That number will grow. The U.S.-Japan collaboration, JUSTIPEN, has thrived to the point that a “theory wing” will be built to provide work space for visiting researchers. The new wing will be adjoined to the auditorium on the front of the joint institute, where researchers will continue to tackle the toughest problems in nuclear physics.

—Reported by Bill Cabage |

ORNL’s Jaguar helps in design of clean coal tech

ORNL’s Jaguar helps in design of clean coal tech

|

An artist’s rendition depicts the goal of the FutureGen initiative, which aims to build the world’s first integrated sequestration and hydrogen production research power plant based on coal gasification. |

In prehistoric times, plants died in swamps

and water thwarted their oxidization. Over time, geological processes pressurized and mineralized the plants, which turned to coal. Today, researchers at the National Energy Technology Laboratory and ORNL are using supercomputers to improve the industrial design of facilities that tap coal’s oxidative potential while trapping its pollutants.

“An important part of NETL’s mission is to supply clean coal technology, and our research group at NETL develops computational tools and applications in support of that mission,” says principal investigator Madhava Syamlal of NETL. With his team and ORNL’s Sreekanth Pannala, he uses the Cray XT4 Jaguar supercomputer at ORNL’s Center for Computational Sciences to simulate coal gasification processes. The highest-resolution coal-gasification simulation to date should enable faster development of clean coal technology.

The research contributes to clean coal technology projects using advanced power generation technologies such as Integrated Gasification Combined Cycle, or IGCC. Next-generation IGCC plants are envisioned that emit nearly no nitrogen oxide, mercury or sulfur and that trap most carbon dioxide.

In gasification, coal is pulverized and partially oxidized to separate fuel-rich hydrocarbons from pollutants. Coal solids are recycled through the system until they are completely gasified to produce “syngas,” a mixture of hydrogen and carbon monoxide. The syngas can be used to produce hydrogen or to generate electricity (for example, using gas turbines) in a clean and efficient manner.

“The United States has more than 200 years of mineable coal reserves at current consumption rates,” says Sreekanth. “Coal is also an integral part of the world’s energy mix and is especially a source of energy in the rapidly developing economies of India and China. This research will benefit the world through development of clean coal technologies.”

The motivation for investment to accelerate high-risk, high-rewards research is clear, Sreekanth says. Unless the production of hydrogen and electricity from coal, integrated with sequestration of carbon dioxide, is shown to be feasible and cost effective, the industry will not make investments needed to fully achieve the energy and economic benefits of coal.

In the mid-1990s, industry and government collaborated to build coal gasification research and development test facilities to design advanced technologies. In response to supercomputer simulations, engineers adjust operating conditions to learn what works best.

“Essentially, we’re trying to get the highest-resolution data to date for coal gasification to feed into these test facilities,” NETL’s Chris Guenther says. “For example, it’s critical to understand the impact inlet ports for coal have on the gasification process. Inlets are important and are a challenging area of research because of the complex mixing, chemistry and temperature gradients that exist in these areas. Correctly capturing inlet regions is critical in our simulations, not only to understand local conditions in these areas, but also to understand how injection of coal can impact the conversion of coal into syngas.”

To examine injection ports in detail, the NETL researchers ran simulations on Jaguar for two weeks in January. Jaguar’s high resolution—down to one millimeter— enables simulations that represent reality with unprecedented fidelity.

The supercomputer’s enormous memory and speed produce quicker answers to scientific and engineering questions and accelerate development of the technology.

“There’s a move toward modeling instead of building expensive prototypes,” says Ramanan Sankaran, an ORNL liaison who optimizes code so researchers can wrest the most science from the supercomputers. Guiding the design process through simulation rather than trial-and-error speeds the development of an experimental prototype that works, he says. “Once that prototype is built, researchers can run different experiments

and get a new answer every hour.” – Dawn Levy

NCAR’s Hack to lead NCCS, climate initiative

NCAR’s Hack to lead NCCS, climate initiative

|

Hack |

James J. Hack, a senior scientist at the National Center for Atmospheric Research in Boulder, Colo., has been appointed director of ORNL’s National Center for Computational Sciences.

“We are thrilled that Jim Hack is joining us to lead America’s premier open computing facility,” says Lab Director Thom Mason. “Jim is a global leader in climate research and has devoted his career to gaining insight into Earth’s atmosphere, where dynamics are complex and a lot is at stake. He is well suited to lead the NCCS in addressing the grand scientific challenges of this century, which include climate but also extend to fields such as biology, chemistry, physics and even computation itself.”

NCCS supercomputers provided more than one-third of the simulation data jointly contributed by DOE and the National Science Foundation to the most recent assessment report of the United Nations’ Intergovernmental Panel on Climate Change, the group that shared the 2007 Nobel peace Prize with Al Gore. Hack was one of the principle developers of the model that was run on the NCCS supercomputers.

“Jim brings to the NCCS a depth of experience wresting great science from the world’s most powerful machines,” Associate Laboratory Director for Computing and Computational Sciences Thomas Zacharia says. “The goal of supercomputing is deep insight, and with Jim’s leadership the nation’s top researchers will make the most of petascale computing.”

Jim will join Leadership Computing Facility Project Director Buddy Bland in identifying major high performance computing needs from scientific and hardware perspectives and put forth strategies to meet those needs as machines evolve to the petascale and beyond.

He also will lead the Climate Change Initiative at ORNL, directing a team of scientists and engineers across the Laboratory in advancing the state of the art in Earth system discovery and policy through enhanced scientific understanding, Earth system modeling, and computational and observational programs.

New Safeguards Lab puts the expertise behind ‘verify’

New Safeguards Lab puts the expertise behind ‘verify’

|

Bert Rollen displays a gamma-ray detector, part of the Safeguards Lab’s trove of instruments. |

ORNL has added to its list of user

facilities. The Safeguards Laboratory offers capabilities to a variety of groups and individuals at a level hard to find outside a national laboratory.

The lab, newly located on the ground floor of the Engineering Technology Facility, is a one-of-a-kind national user facility for the calibration, verification and validation of radiation measurement and detection instruments. The Safeguards Lab also trains various individuals on the implementation and use of the equipment.

“There isn’t another place in the DOE complex like this one, so DOE worked with us and designated us as a national user facility,” says Bert Rollen, the deputy operations manager for the Nuclear Science & Technology Division lab.

Proper calibration of radiation detection and measurement equipment and the training on how to use them are vital because these instruments are critical tools in detecting and safely storing radioactive materials—thus the name Safeguards Laboratory.

Customers have come from all over the globe, including the Department of Homeland Security, the International Atomic Energy Agency and Euratom, among others.

The laboratory’s training program is tailored to people of all technical levels, ranging from “this is an atom” basics to teaching participants how to calibrate their instruments and perform verification measurements in nuclear facilities.

“This service supports national and international nuclear nonproliferation programs by providing a capability for improving the effectiveness and efficiency of international verification regimes,” Bert says.

The center is also helping countries locate and secure nuclear materials that were previously stored or used under vulnerable conditions. In one example, the government of South Africa was left with a stock of nuclear materials, including barrels of enriched uranium, after its former apartheid government gave up on its nuclear weapons program years ago. The Safeguards Lab, working with DOE, trained a cadre of South African inspectors and showed them how to set up an assay program.

The work can be complicated. In most cases it’s advantageous to characterize and measure packages of suspected nuclear material noninvasively—without opening them. With the proper techniques and the right detection instruments, inspectors can do that.

Likewise, accurately measuring uranium that has migrated through piping or conduit systems is tricky. Uranium can collect in crannies at any point in a system, a phenomenon called holdup. The Safeguards Lab has mockups of a conduit and a piping system that Bert and his colleagues use to mimic holdup situations found in facilities that process nuclear materials. Radioactive sources are hidden in the mockups, and trainees are asked to locate, characterize, and quantify them.

The lab works closely with Texas A&M University, which has a strong program in radiation detection and verification. Several students have come to ORNL to work in the lab, and some have wound up on the staff. Students get hands-on experience with an array of instruments used in gamma-ray detection and spectroscopy and, to a lesser degree, neutron measurement.

In the “trust but verify” mantra of international inspectors, the Safeguards Lab puts the confidence behind the “verify.” As a national user facility, its resources are available to the broader user community outside the national laboratory system.—B.C. ![]()

Furry friend on site: He’s training for a canine career

Furry friend on site: He’s training for a canine career

|

If Timmy’s wearing his bright yellow jacket, it mean’s he’s working. |

A dog has been spotted on the ORNL

campus. No need to call animal control; this one’s training for an important job.

Timmy, a pure-bred golden Labrador puppy, is a candidate guide dog owned by the Guide Dog Foundation for the Blind, Inc., headquartered in Smithtown, N.Y. He’s under the charge of the Diversity and International Services Office’s Connie Nichols, who has the enviable task of raising and training him for the next year.

Then Connie will have the unenviable task of sending Timmy back to New York to complete training to—if he meets the requirements—help a handicapped person negotiate the rigors of life.

The pup is adorable, especially when he’s wearing his little identification jacket. Connie cautions her colleagues that to help Timmy pass muster, there are certain ways we should treat the dog when we encounter him on the site.

“As part of Timmy’s training, it is important that he learn to follow my instructions and directions, so when you see us walking around campus, please do not pet him or talk to him if he has his identification jacket on,” Connie says.

When the jacket is on Timmy, he knows he is “working,” and when the jacket is off, he knows he can play and relax a little, she says.

“One of the hardest parts of the training is asking people to not pet him or feed him treats. Timmy has to follow a very strict routine and diet so that he can make life easier for a blind person,” she says.

ORNL has hosted canine candidates before. In 1993 another golden retriever named Epstein did a stint at the Lab to train for a program called Canine Companions.

Connie encourages you to talk to her when you see her with Timmy and ask any questions. Timmy is the sixth guide dog puppy she’s worked with. She says she is looking forward to sharing this experience with the entire

Labrador-atory.—B.C. ![]()

|

|---|

Benefits at Oak Ridge National Laboratory may be a big reason people come to work here, but that doesn't always mean the various available programs, from 401K savings plans to flexible spending accounts, are easy to comprehend. ORNL Benefits Manager Mark Wagner and Brian Mullins, an investment representative from the ORNL Credit Union, presented information about benefits and financial planning to a standing-room-only crowd gathered for a Committee for Women forum, held Jan. 30 at the Joint Institute for Computational Sciences. Brian Mullins first discussed a basic strategy for financial planning. He offered the following guidelines: • Contribute at least what your employer matches to your 401K savings plan. • Be on track to have your home mortgage paid off by your target retirement date. • Maximize the allowable contribution to a Roth IRA, a savings program in which contributions are non-deductible but withdrawals are tax-free when a person turns 59 1/2. • Determine if you have enough saved for retirement through the following formula: total income – 401K contribution – house payment – any other payments that cease with retirement – pension income. Divide that total by .05 (traditional multiplier) or .03 (more conservative) to determine the amount you need to carry you through retirement. Mark Wagner then provided an overview of benefits. Some interesting points: • Long-term care benefit: You may never need it, he said, but if you do require long-term care, the benefit protects your assets and pays for what is now on average the $80,000-per-year cost of staying in a dependant care facility. About 15 percent of employees at ORNL are taking advantage of this benefit. • Flexible spending accounts: On the medical side, the big advantage is that employees may spend the full amount of their commitment for the year at any time during the year, whether it has been paid into the account or not. The accounts can be used for day care as well, with a rule-of-thumb savings of $250 in taxes for $1000 paid into the program. Mark advised, however, that this number is based on an individual's tax bracket and that employees should compare this benefit with the childcare dependent tax credit, which they can take at tax time each year. • Retirement investment: Because of the uncertainties in Social Security, early-career employees should plan to save 100 percent of their needed income, post-retirement. Mid- and late-career employees require 80-90 percent savings. At ORNL, close to 800 people are not maximizing the employer match by not contributing at the 6% amount which takes advantage of the 401K matching program, which, Mark added semi-tongue-in-cheek, he would make mandatory if possible. “It's just throwing away free money,” he said. Additionally, 86 percent of ORNL employees are choosing their own investments rather than depending on the models available through our 401K savings program. “That's opposite of what the studies have shown,” he said, which is that 80% of investors don't have the acumen to manage their own accounts. |

New Staff

Members

New Staff

Members

December

Rayshell Annette Booker, National Security Dir.

Malinda Summers Devaney and Lynn Ellen Stulberg, Human Resources Dir.

Brian Elmer Fuller, Jonathon Graham Wall and James Jeffrey

Duckett, NScD Research Reactors

William Barton Bailey, NScD Neutron Facilities Development

Jo Ann Emory, Engineering Science & Technology

Tim Jerome and Paula Lee Lindsey, Information Technology Services

Sidney Michael Kilbey II, Center for Nanophase Mat’ls Sciences

Darrell Gene Lawson, Laboratory Protection

Matthew Brandon Stone, NScD Neutron Scattering Science

Norbert Podhorszki, Center for Computational Sciences

January

Agatha Anna Bardoel, Computing & Computational Sciences Dir.

Hongbin Bei, Materials S&T

David Allen Deibler, NScD Research Reactors

Jennifer Denton Haun and Shelia Browning Ross, Nonreactor Nuclear Facilities

Shaun Hughes and Stephen Edward Stewart, NScD Neutron Facilities Development

Eva Genice Todd and Dawn Elizabeth Ridz, Human Resources Dir.

Gaute Hagen, Physics

Kai-Yao Lin, Biosciences

Ann Marie Robbins, Nuclear & Radiological Protection

Lisa Disney Stone, Global Initiatives Dir.

Angela Lynn Thornton and Elizabeth A. Krispin, Nuclear S&T

Tammy Lynn Barnhart and Nathan Eric Daugherty, Center for Nanophase Matl’s Sciences

Albert William Borum III, Safety Services

Roberta Renae Speck, Technology Transfer

Linda Gail Kincaid, Facilities Management

Michael Craig Knight, NScD Research Accelerator

Robert R. Dejarnette, Jr., NScD Neutron Scattering Science

Mary Beth Lascurain, Austin Peter Albright and Benjamin Edward Huey, Engineering S&T

Steven Michael Hartman and Katherine Elaine Fielder Tomb, NScD

Research Accelerator

Steven John Meitner, Fusion Energy

Alesia Rae Swicegood, Health Services

Margaret Allen Taylor, Contracts Division (transfer) ![]()

ORNL People

ORNL People

David Greene, corporate fellow in the Transportation Policy and Planning group, Engineering Science & Technology Division, has been appointed to a three-year term on the Transportation Research Board Special Task Force on Energy and Climate Change. The task force coordinates the activities of, and facilitates communication among, the TRB standing committees regarding the cross-cutting issues of global climate change and energy.

The Computer Science & Mathematics Division’s Nageswara Rao and Mike Simpson, leader of the Nanofabrication Research Laboratory in the Center for Nanophase Materials Sciences, have been elected fellows of the Institute of Electrical and Electronics Engineers, Inc. The IEEE cited Nagi “for contributions to algorithms for reliable communication in distributed sensor networks.” Mike was recognized for his contributions to nanotechnology in engineering devices and biology.

Neutron scientist Bryan Chakoumakos was recently elected a fellow of the Mineralogical Society of America. A member of the Neutron Scattering Science Division, Bryan leads the Single-Crystal Diffraction group.

The Environmental Sciences Division’s Patrick Mulholland received the Strategic Environmental Research and Development Program (SERDP) Project of the Year Award in Washington, D.C., recently. Pat’s project, titled “Riparian Ecosystem Management: Impacts, Restoration and Enhancement Strategies,” was cited at the 13th annual Partners in Environmental Technology Technical Symposium & Workshop.

The Chemical Sciences Division’s M. Parans Paranthaman and the Materials S&T Division’s Amit Goyal were guest editors of a recently published special issue of the Journal of Electronic Materials (Vol. 36, November 10, 2007) devoted to high-temperature superconductivity research and development. Parans has also co-authored a book on flux pinning and AC loss studies on YBCO-coated conductors.

The Chemical Sciences Division’s Gary J. Van Berkel, group leader and senior research scientist in the Organic & Biological Mass Spectrometry group, has been selected to serve a three-year term on the editorial advisory board of the journal Analytical

Chemistry.

The Neutron Scattering Science Division’s Ashfia Huq was recently awarded the Mary Lyon Award by the Alumnae Association of Mount Holyoke College. The award is presented to an outstanding young alumna who has been out of college 15 years or less. Ashfia is an instrument scientist with POWGEN3, a third-generation powder diffractometer at the Spallation Neutron Source.

The Environmental Sciences Division’s Tony King has been selected co-chair of the North American Carbon Program’s science steering group. Tony, of the Ecosystem Simulation Science group, will share duties with Penn State’s Ken Davis.

Former ORNL Director Bill Madia has been appointed vice president for the Stanford Linear Accelerator Center by Stanford University President John Hennessy. Madia’s newly created position will “provide direct linkage between the university and the laboratory, enhance collaboration and ensure coordination between the laboratory, Stanford and the Department of Energy.”![]()