ORNL to lead one and participate in two projects on non-vapor compression technology research

ORNL will lead or participate in 3 of 7 projects recently funded through a funding opportunity announcement (FOA) awarded by the US Department of Energy Building Technology Office. Of the $7.6 million that DOE awarded, ORNL is involved in projects receiving $4.3 million, $2.2 million of which will be used for in-house research. Each research and development project is focused on the advancement of next-generation heating, ventilating, and air conditioning (HVAC) technologies, supporting DOE's goal of developing cost effective, energy efficient technologies that also reduce the use of chemicals that have a negative effect on the global climate.

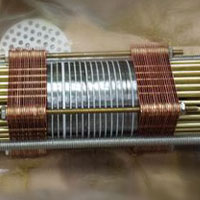

ORNL will receive about $1.4 million to develop a novel magnetocaloric air conditioner with the potential for efficiency improvements of up to 25% over conventional vapor compression systems, equivalent to saving 1 quad of energy annually for space heating and cooling in the U.S. residential sector. The system moves copper, brass or aluminum rods in and out of a magnetic field. The temperature of the rods will transfer the heat to and from the magnetic regenerative bed whose temperature changes as the magnetic field changes. This heat is transfer through forced air at both ends of the magnetic regenerator. The window air conditioner concept could possibly be scaled up to larger systems.

In partnership with Dais Analytic (Odessa, Florida), ORNL will work on a $1.2 million project to advance membrane HVAC technology that will use nanostructured polymer materials (membrane) to manipulate water molecules, allowing the system to condition air while improving energy efficiency and eliminating the need for fluorocarbon refrigerants. The project will result in a rooftop-capable system for field evaluation. With Xergy, Inc. (Seaford, Delaware), ORNL will participate in a $1.4 million project to develop electrochemical compression (ECC) technology in combination with an energy recovery module to replace traditional electromechanical compressors for use in heat pumps. ECC uses fuel cell technology to enable heat pumps to use water as the refrigerant. Thermodynamic modeling shows efficiency improvements of 30-56% are attainable in a commercialized system. The project seeks to produce a unit with a 5-year or better payback period when produced at commercial scale.

Click here to read the full announcement.