Research - Multifunctional Nanotube Composites

Multifunctional

Carbon Nanotube Composites

Carbon nanotubes can lend new functionality to polymer, metal, or carbon matrices – enhancing their strength and also their thermal conductivity and electrical conductivity. Single-walled carbon nanotubes (SWNTs) have huge tensile strengths (Young's modulus over 1 TPa, considered one of the strongest materials known to man). They are also excellent thermal conductors and electrical conductors, and have been developed as single-electron transistors, actuators, sensors, memory elements, and recently electroluminescent emitters. Due to small production quantities in the past, research to date has concentrated on small-volume applications (electronics, sensors, etc.). However with large-scale SWNT synthesis under development worldwide, the science of forming strong, lightweight composites which retain the desirable properties of SWNTs is underway. Nanotube-based composites have the potential to revolutionize structural materials for aerospace, electrical and thermal conductors for energy applications, nano-biotechnology, and other disciplines. Through an internally-sponsored ORNL project, and with NASA and DARPA support, we are exploring the synthesis of polymer nanocomposites, metal-matrix nanocomposites, and carbon-carbon composites using loose SWNTs and multiwalled carbon nanotubes (MWNTs).

Research at ORNL in Multifunctional Nanotube Composites Include:

Synthesis and Purification of Loose Single-Wall Carbon Nanotubes for Composites -

Loose

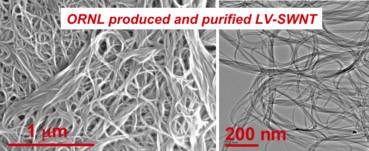

SWNTs are synthesized, purified, and functionalized at ORNL. SWNTs are synthesized

by laser vaporization in grams quantities (see facilities section) and the

synthesis conditions have been adjusted for compatibility with chemical purification

treatments to enable the near complete removal (<0.2 wt. %) of metal impurities.

Loose

SWNTs are synthesized, purified, and functionalized at ORNL. SWNTs are synthesized

by laser vaporization in grams quantities (see facilities section) and the

synthesis conditions have been adjusted for compatibility with chemical purification

treatments to enable the near complete removal (<0.2 wt. %) of metal impurities.

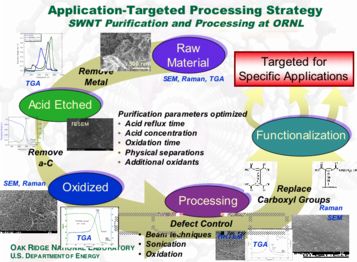

Each

batch of raw SWNTs is purified slightly differently, based upon TGA and Raman

diagnostics in collaboration with Dr. Phil Britt at ORNL. Our research together

has concentrated upon varying the defect levels in the purified SWNTs to enable

chemical functionalization targeted for particular applications (e.g. strength

via strong covalent bonds with polymer matrices).

Each

batch of raw SWNTs is purified slightly differently, based upon TGA and Raman

diagnostics in collaboration with Dr. Phil Britt at ORNL. Our research together

has concentrated upon varying the defect levels in the purified SWNTs to enable

chemical functionalization targeted for particular applications (e.g. strength

via strong covalent bonds with polymer matrices).

Vertically-Aligned Multiwall Carbon Nanotube Arrays for Composites

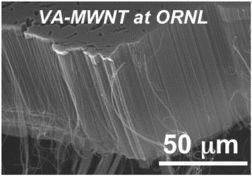

Vertically-aligned

multiwall carbon nanotube (VA-MWNT) arrays are grown from metal catalyst films

at ORNL by thermal CVD (see facility section). Mixed with the MWNT are SWNT

at most processing temperatures. Using time-resolved diagnostic techniques

for this material system, the kinetics of nanotube growth by thermal CVD are

being studied – providing some of the first direct measurements of nanotube

growth rates, and providing the ability to control the length of the aligned

arrays (in press). Research is concentrating upon understanding what

stops nanotube growth, how growth can be continued to long lengths (millimeters

and longer), and methods to increase the growth rate so that long, continuous

nanotube fibers can be produced for composites.

Vertically-aligned

multiwall carbon nanotube (VA-MWNT) arrays are grown from metal catalyst films

at ORNL by thermal CVD (see facility section). Mixed with the MWNT are SWNT

at most processing temperatures. Using time-resolved diagnostic techniques

for this material system, the kinetics of nanotube growth by thermal CVD are

being studied – providing some of the first direct measurements of nanotube

growth rates, and providing the ability to control the length of the aligned

arrays (in press). Research is concentrating upon understanding what

stops nanotube growth, how growth can be continued to long lengths (millimeters

and longer), and methods to increase the growth rate so that long, continuous

nanotube fibers can be produced for composites.

VA-MWNT can be grown directly into sensor patterns by prepatterning the metal catalyst lithographically. Photolithography and e-beam lithography techniques are both used.

We have developed techniques to infiltrate VA-MWNT with polymers and other matrices while preserving their alignment. In addition to enhancing the Young's modulus of polymers while retaining their hardness, these composites are being developed for greatly enhanced (anisotropic) thermal conductivity, electrical conduction and static charge dissipation, and sensor functionalities.

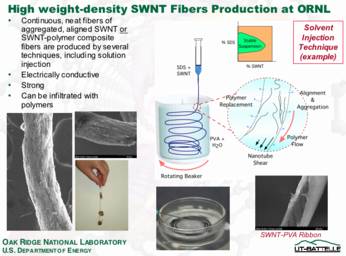

High Weight-Density SWNT Fibers

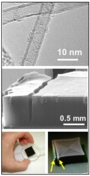

High

weight-density fibers of SWNT are spun from solubilized or suspended SWNT

in surfactant or other solutions. Millions of single-wall carbon nanotubes

roughly align along the fiber axis as the surfactant solution is injected

into another liquid. Single-wall nanotubes aggregate readily, forming a high

weight-density fiber which can be back-infiltrated with polymers or other

materials to form composite fibers. The fibers are strong and electrically

conductive. Research is concentrating on methods of fiber production, nanotube

solubilization, mechanical testing, and processing of fibers for predesigned

functionality.

High

weight-density fibers of SWNT are spun from solubilized or suspended SWNT

in surfactant or other solutions. Millions of single-wall carbon nanotubes

roughly align along the fiber axis as the surfactant solution is injected

into another liquid. Single-wall nanotubes aggregate readily, forming a high

weight-density fiber which can be back-infiltrated with polymers or other

materials to form composite fibers. The fibers are strong and electrically

conductive. Research is concentrating on methods of fiber production, nanotube

solubilization, mechanical testing, and processing of fibers for predesigned

functionality.

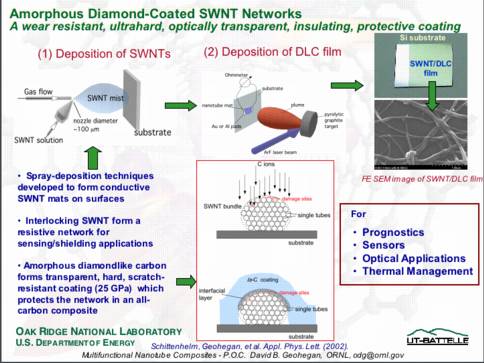

Functional Thin Film Networks of Single-Wall Carbon Nanotubes

We

are studying how networks of single-wall carbon nanotubes conduct electricity

in polymers. Generally, SWNTs remain in bundles within polymers. They form

a complicated, interlocking resistive network of interconnected bundles, which

acts as a sensor web.

We

are studying how networks of single-wall carbon nanotubes conduct electricity

in polymers. Generally, SWNTs remain in bundles within polymers. They form

a complicated, interlocking resistive network of interconnected bundles, which

acts as a sensor web.

Techniques have been developed to spray, spin, and cast SWNT in thin films for applications. And methods of alignment of SWNT within these films have been developed. Alignment of SWNT within polymer thin films is measured by polarized Raman spectroscopy (see facility description).

At left, a nanometers-thin coating of amorphous diamond was applied to a resistive SWNT network which had been spray -deposited from solution. Amorphous diamond is pure carbon, just like carbon nanotubes, however its bonding is ~70% like that of diamond. Hence it is optically transparent, hard, and insulating in contrast to the properties of nanotubes. This all carbon composite (amorphous diamond on SWNTs) preserved the resistive nanotube network within a highly scratch resistant, optically transmissive, diamondlike protective matrix.

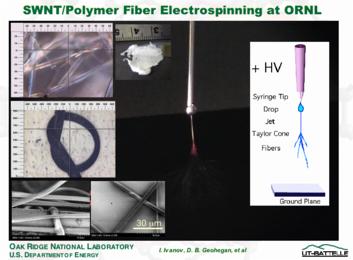

Electrospun Nanotube-Polymer Fibers

We

are experimenting with spinning polymer fibers which contain single-walled

carbon nanotubes for a variety of enhancements, including conductivity, thermal

stability, sensing capabilities, and communication. Electrospinning involves

co-solubilizing polymer and nanotubes in a common solvent. This solution is

drawn from a syringe by a strong electric field. As the solvent dries, the

polymer/nanotube fiber forms enroute to a ground plane. The diameters of the

fibers can be varied by adjusting the viscosity of the solution.

We

are experimenting with spinning polymer fibers which contain single-walled

carbon nanotubes for a variety of enhancements, including conductivity, thermal

stability, sensing capabilities, and communication. Electrospinning involves

co-solubilizing polymer and nanotubes in a common solvent. This solution is

drawn from a syringe by a strong electric field. As the solvent dries, the

polymer/nanotube fiber forms enroute to a ground plane. The diameters of the

fibers can be varied by adjusting the viscosity of the solution.

We are investigating the degree of alignment of nanotubes within the electrospun fibers as a function of weight loading and fiber diameter using polarized confocal microRaman spectroscopy.

A great variety of nanotube-polymer composites can be formed for mechanical testing and functionality assessment by electrospinning.

Nanotube Papers

|

Carbon nanotubes can also be cast into papers by a variety of techniques, including methods which produce high degrees of alignment as measured by polarized Raman microscopy (see Facilities section). |