| Research

|

|

|||||||||||||||||||||||||||

|

Argonne system takes salt from syrup Each year, industry generates millions of gallons of toxic chemical waste while producing food, fuel, textiles, cosmetics and pharmaceuticals. Efforts to improve these expensive and dirty processes have been delayed by technical barriers—until now. Researchers at DOE's Argonne National Laboratory have developed a cleaner, cheaper salt-removal process that cuts chemical use by 90 percent while matching the existing technology's output. Researchers successfully demonstrated the process that removes salt, a natural byproduct of corn-syrup production, in a high-fructose corn syrup refinery in Lafayette, Ind.

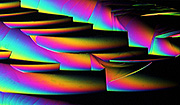

The improved EDI technology was named one of this year's top 100 inventions by R&D magazine. Argonne's EDI device could replace conventional ion-exchange technology and reduce energy costs and potential pollution by eliminating the need for chemical regeneration. This innovative device may have applications in cleaning radioactive and bio-based wastes. The key to this process is an Argonne-designed porous wafer and gasket system coupled with a refinement to an existing purification process called electrodeionization (EDI). EDI combines electricity and ion exchange, which is a chemical process that separates charged molecules. Every year, the United States pumps out more than 9 million tons of corn syrup to sweeten candy, soft drinks and ice cream. To make high-fructose corn syrup, salt-based enzymes are added to corn starch—a chain of glucose molecules—to convert it into a syrupy mixture of water, dextrose and fructose sugars. Argonne's Energy Systems Division scientists Seth Snyder, Paula Moon, Michael Henry, Yupo Lin, James Frank and Carl Landahl joined forces with EDSep Inc., based in Mount Prospect, Ill., to develop a cleaner, more energy-efficient alternative. EDSep works with scientists to commercialize proprietary technology. Submitted by DOE's Argonne National Laboratory |