| Research

|

|

||||||||||||||||||||||||||

|

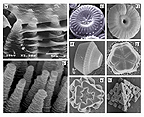

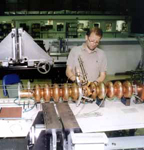

Unlocking metallic glass' mysteries DOE's Ames Laboratory researchers Dan Sordelet and Matt Kramer are working to understand why metallic glasses take on various structures and properties depending on how the materials were processed. Normally, metals have a very regular (periodic) structure in which the atoms align. This ordered arrangement contains damage mechanisms that allow crystalline metals to be permanently bent or dented. By definition, glass - including the common window variety - is formed when a material is synthesized in such a way that a regular crystalline structure isn't formed. This random, or amorphous, arrangement of atoms gives metallic "glass" the ability to snap back into its original shape instead of deforming - as long as it's not bent too far. These fascinating materials have a number of unique physical and sometimes electrical and magnetic properties but are difficult to study because of the ways and speeds with which they form. The materials Sordelet and Kramer are studying have been melt-spun - a stream of molten metal is dropped onto a spinning copper wheel and solidifies in a ribbon before the atoms can line up. They are also looking at metallic glass formed by high-energy mechanical milling that destroys the crystal structure to such an extent that it becomes amorphous, and by laser deposition in which a laser vaporizes materials into highly energetic atoms that condense randomly in a thin coating. With all of these contrasting synthesis methods, it's difficult or impossible to find out what's taking place at the atomic level as the amorphous structure forms. So the two researchers work backwards, in a way, through a process called devitrification. This involves gradually heating the metallic glass until it devitrifies - loses its amorphous properties - and the atoms realign in the metal's regular crystalline pattern. "From a fundamental viewpoint, we want to try to make the linkage between the structure that's in a liquid and the resulting amorphous structures that we see," Kramer says, "and identify the relationship of the short-range order in the glassy alloy and the role it plays in phase selection as the materials devitrify." The Ames Lab research group is relying on the Advanced Photon Source (APS) synchrotron radiation source at Argonne National Laboratory to analyze the materials. Using a novel furnace Kramer helped design and build for the Midwest Universities Collaborative Access Team at APS, the team gradually heats samples of zirconium-palladium (Zr70Pd30) while using the high-energy beam line radiation to produce X-ray diffraction images of the material's atomic structure. To take some different "snapshots" of the materials, Sordelet and Kramer are collaborating with researchers from the Centre National de Recherche Scientifique (CNRS) at the Ecole des Mines in Nancy, France, to utilize accelerator facilities in Oxford, England, and Grenoble, France, where neutrons are used to bombard the samples instead of photons. While the researchers admit they aren't precisely sure where their work will lead in gaining new fundamental insight into the infinite range of amorphous structures of metallic glasses, there could be some practical applications that come out of it. Kramer points out that one of the keys to forming nanoscale materials is to control devitrification. Submitted by DOE's Ames Laboratory |