| Research

|

|

|||||||||||||||||||||||||||||

|

Check out symmetry—the

|

Sandia, General Motors focus on |

|

|---|

|

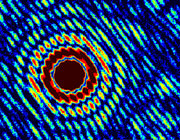

A critical aspect of hydride storage tank development is the act of recharging and discharging hydrogen. Here, Sandia National Laboratories engineer Mark Zimmerman integrates a hydride bed with temperature monitoring sensors.

|

General Motors and DOE's Sandia National Laboratories have launched a partnership to design and test an advanced method for storing hydrogen based on metal hydrides.

Metal hydrides— formed when metal alloys are combined with hydrogen—can absorb and store hydrogen within their structures, then, when subjected to heat, release their hydrogen. In a fuel cell system, the hydrogen can then be combined with oxygen to produce electricity.

Sandia and GM have embarked on a four-year, $10 million program to develop and test tanks that store hydrogen in a complex hydride—sodium aluminum hydride, or sodium alanate. The goal is to develop a pre-prototype solid-state hydrogen storage tank that would store more hydrogen onboard a fuel cell vehicle than current conventional hydrogen storage methods. Researchers also hope to create a tank design that could be adaptable to any type of solid-state hydrogen storage.

Researchers at both GM and Sandia say the program is part of a concerted effort to find a way to store enough hydrogen onboard a fuel cell vehicle to equal the driving range obtained from a tank of gasoline, which will be key to customer acceptance of fuel cell vehicles.

The current leading methods of storage are liquid and compressed gas. To date, however, neither of these technologies has been able to provide the needed range and running time for fuel cell vehicles.

“We are designing a hydrogen storage system with challenging thermal management requirements and limits on volume and weight,” says Chris Moen, manager of Engineering and Science Technologies at Sandia's California lab. “Our staff researchers are excited to apply their unique, science-based design and analysis capabilities to engineer a viable solution.”

“We know a lot of research still needs to be done, both on the types of hydrides we use, as well as the tanks we store them in,” says Jim Spearot, director of GM's Advanced Hydrogen Storage Program. “We think our work on projects like this with Sandia will get us another step closer to our goal.”

In the first of the project's two phases, researchers will study and analyze engineering designs for a sodium alanate storage tank using thermal and mechanical modeling, develop controls systems for hydrogen transfer and storage, and develop designs for external heat management. GM and Sandia scientists will also be testing various shapes—from cylindrical to semi-conformable—to see which are the most promising.

In the second phase, researchers will subject promising tank designs to rigorous safety testing and ultimately fabricate pre-prototype sodium alanate hydrogen storage tanks based on knowledge gained from the program's first phase.

“This is the kind of public-private research partnership that will help us realize the president's vision, communicated in his 2003 State of the Union address, that ‘the first car driven by a child born today can be powered by hydrogen, and pollution-free,'” DOE Secretary Spencer Abraham said of the project. “Over the long term, because of the president's visionary leadership, clean, efficient hydrogen fuel technologies like this will help make our nation far less reliant on foreign sources of energy.”Submitted by DOE's Sandia National Laboratories