Research

Highlights...

|

|

Number 187 |

July 5, 2005 |

|

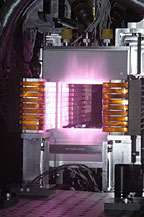

World's most powerful diode pumped solid state laser

A revolutionary new laser under development at DOE's Lawrence Livermore National Laboratory could drastically reduce casualties by U.S. forces. The Solid State Heat Capacity Laser program has already successfully achieved world-record energy output. The system will eventually allow infantry units to use a beam of invisible light to destroy incoming mortars, artillery shells and anti-tank missiles, as well as defusing buried landmines. The Army's Space and Missile Defense Command is sponsoring the program, which uses a unique pulsed beam that fires 200 times per second, and can already easily burn a hole through an inch of carbon steel in approximately seven seconds.

[Bob Hirschfeld, 925/423-2379,

hirschfeld2@llnl.gov]

|

|

INL tests advanced fuel cell technology for industry

Scientists and engineers at DOE's Idaho National Laboratory have tested and successfully demonstrated, for the first time, the technical feasibility of directly connecting a catalytic partial oxidation diesel reformer to a 5-kilowatt solid oxide fuel cell system – converting the diesel fuel into a hydrogen-rich synthesis gas and passing the gas through a fuel cell to generate electricity. The purpose of this unique three-day test was to gather data to design and integrate a new and revolutionary diesel-powered solid oxide fuel cell system. Ultimately, scientists say, by designing a heat recovery unit into the next-generation system, an efficiency rating of 80 percent can be achieved.

[Reuel Smith, 208/526-3733,

Reuel.Smith@inl.gov]

|

|

Lighting solution for the developing world

|

Berkeley Lab's Evan Mills holds a prototype white light-emitting diode. |

An energy-efficiency expert with DOE's Lawrence Berkeley National Laboratory (Berkeley Lab) has calculated that replacing kerosene and other fuel-based lighting systems in developing nations with highly-efficient, cost-effective white light-emitting diode lighting systems could save tens of billions of dollars per year worldwide in energy costs, and also dramatically reduce carbon dioxide emissions. In a paper published in Science, Berkeley Lab's Evan Mills showed that fuel-based lighting now consumes the energy equivalent to 1.3 million barrels of oil per day, and gives off about 190 million metric tons of CO2 emissions per year, equivalent to one-third the total emissions from the United Kingdom.

[Lynn Yarris, 510/486-5375,

lcyarris@lbl.gov]

|

|

Spotting spins in a cryogenic vise

Scientists at DOE's Los Alamos National Laboratory have developed a novel method for controlling electron spins in gallium arsenide semiconductor crystals. By mounting the crystals in an optical cryostat and using a miniature "cryogenic vise" to apply gentle pressure, researchers were able to watch the electron spins rotate as they flow through the crystal. The cryogenic vise operates at only a few degrees above absolute zero and can be used to intentionally tip, rotate, and flip the electron spins without applying magnetic fields. The work suggests an alternative method of spin manipulation for use in future generations of "spintronic" devices.

[Todd A. Hanson, 505/665-2085,

tahanson@lanl.gov]

|

|

New "biosensor" screens contamination within minutes

|

The DNA Capture Element instrument was developed at the Pacific Northwest National Laboratory for the Air Force Research Laboratory. The "green box" is used to process samples of agents – in a matter of minutes – to determine if they are or aren't harmful. |

Air Force personnel will soon know within minutes if they or their equipment are contaminated with a biological agent, thanks to a new technology developed by the Air Force and DOE's Pacific Northwest National Laboratory. Airmen and other personnel will use the biosensor system to collect and isolate samples, detect and identify agents, and assess the seriousness of the threat. The system consists of a spray developed at the Air Force's Brooks City-Base in Texas and a hand-held "green box," which determines if agents are present. The green box, or DNA Capture Element instrument, was developed by researchers at PNNL. The biosensor system is designed to be reliable, disposable and cost-effective. The Air Force will continue testing the device over the next several months and the rapid detection capability of the instrument is expected to be useful in other applications, including outside of the armed forces.

[Andrea Turner, 509/375-3893,

andrea.turner@pnl.gov]

|

|

|

Science 'detective story' sparked Seryi's career

It was a book about element 104, known as Rutherfordium, which led a 12-year-old Andrei Seryi to pursue a career in physics. “It read like a detective story,” said Seryi, who now co-leads an

inter national group of over one hundred people on the Internationall Linear Collider (ILC) beam delivery design team from the DOE's Stanford Linear Accelerator Center (SLAC).

Seryi obtained his Ph.D. from the Budker Institute for Nuclear Physics, where he helped design VLEPP, an electron-positron linear collider. His role was to devise the final focus system.

Now, 17 years later, he's doing the same thing. Currently, Seryi, Tomoyuki Sanuki from the University of Tokyo, and Grahame Blair from the Royal Holloway University of London are leading an international group of particle physicists working on the design of a final focus for the ILC, a future polarized electron-positron linear collider that will create collisions with energies from 500 GeV to 1 TeV. This time, however, the challenge is much more difficult.

When the electron and positron beams collide, the particle beams are severely disrupted and particles may be deflected into the detectors located around the collision point. In order to prevent such a scenario which will degrade the detector performance, Seryi and his group are designing a unique configuration for the final focus systems located at the ends of the two twenty-kilometer linear accelerators in the ILC. The particle beams will not collider head-on; instead, they will collider at an angle that is less than

180 degrees. Deciding exactly what the crossing angle will be, however, is the team's main task. "The international group is very active and able to work quite productively," says Seryi, who is excited about SLAC's role in the ILC.

“I think SLAC has a lot of expertise in a wide variety of areas and will play a central role in the ILC,” he said. “Certainly SLAC will play a large role in the beam delivery and final focus design.”

Submitted by DOE's

Stanford Linear Accelerator Center

|

|