Research

Highlights...

|

JLAB's

Alex Dzierba

|

|

|

Number 223 |

November 27, 2006 |

|

Imaging in a FLASH

Using the soft X-ray laser at Deutsches Elektronen-Synchrotron in Hamburg, researchers have for the first time captured a high-resolution image of a nano-scale object before the single, 25-femtosecond laser pulse destroyed the sample. The international collaboration was led by Janos Hajdu of DOE's Stanford Linear Accelerator Center and Uppsala University and Henry Chapman of the DOE's Lawrence Livermore National Laboratory. Successfully demonstrating this technique on a nano-scale object using soft x-rays opens the door for scientists to apply the technique to study atomic-scale objects using hard x-rays. The results are published in the November 12 online edition and the December print edition of Nature Physics.

[ Brad Plummer, 650/926 2282, brad.plummer@slac.stanford.edu]

|

|

Red Storm second-fastest supercomputer, number-one in scalability

A $15 million upgrade to Red Storm, a Cray-built supercomputer at DOE's Sandia National Laboratories, has increased its peak speed from 41.5 to 124.4 teraflops in a computing terrain in which a single teraflop was a big deal only six years ago. Bill Camp, director of Sandia's Computation, Computers, Information, and Math Center, says, "The Cray XT3 supercomputer now dominating the highest end of computing worldwide is based upon Sandia's Red Storm. Scientists love it because they can do bigger science more quickly on it than any other computer in existence, except for molecular dynamics studies on BlueGene/L (Lawrence Livermore National Lab's supercomputer). Otherwise, it's the best thing since night baseball."

[Howard Kercheval, 505/844-7842,

hckerch@sandia.gov]

|

|

Biofuel cells without the bio cells

|

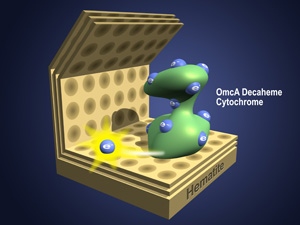

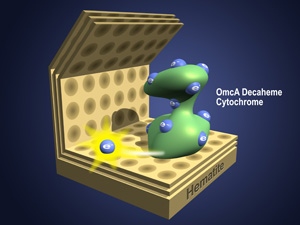

SELF-SEALING BIOCELL: Artist's depiction of purified, electrified bacterial cell outer membrane protein binding with and passing electrons to the iron-rich mineral hematite. In this purified-protein fuel cell, the seal made by the protein coating on the electrode effectively acts in place of a membrane necessary in whole-organism biofuel cells. Eliminating the membrane could aid the design of bioreactors to power small electronic devices. |

Researchers at DOE's Pacific Northwest National Laboratory have observed a first: direct electricity-shuttling from proteins—removed from the outer membrane of the metal-altering soil bacterium Shewanella oneidensis —to a mineral, hematite. The feat is the bacterial equivalent of removing lungs and coaxing the disembodied tissue to breathe. The function is a relic of respiration, in which the cell depends on the protein to dump electrons to maintain a steady flow of energy and prevent the organism-damaging accumulation of electrons. Iron in the hematite acts as an “acceptor,” a dumping point for thousands of trillions of electrons per square centimeter shuttled by the protein, called OmcA. The seal made by an OmcA coating a hematite-electrode effectively acts in place of a membrane necessary in the design of whole-organism biofuel cells. Eliminating the membrane could aid the design of bioreactors to power small electronic devices. The study was recently published in Journal of the American Chemical Society.

[Bill Cannon, 509/375-3732,

cannon@pnl.gov]

|

Savannah River Lab to build hydrogen power system

DOE's Savannah River National Laboratory has teamed with the Center for Hydrogen Research to build and test a prototype system to demonstrate how hydrogen fuel cells can be effectively used to provide an emergency backup power system for hospitals and other critical facilities.

The partners will combine SRNL's unique hydrogen storage technology with a fuel cell capable of generating electricity from hydrogen fuel and an electrolyzer to produce hydrogen. These combined elements will make up a regenerative fuel cell system that will provide a rugged, compact, quick-response, reliable emergency power supply for occasions when grid power is temporarily cut off. The resulting prototype will serve as a model for future larger scale systems that would enhance U.S. energy security by providing safe, reliable, and renewable backup power for a variety of critical applications. This work is part of SRNL's initiatives to work quickly to help the U.S. realize energy security. CHR, a nonprofit organization that is a subsidiary of the Economic Development Partnership of Aiken and Edgefield Counties, is dedicated to promoting partnerships to build the foundations for a clean, secure, safe energy source of the future. [Angeline French, 803/725-2854, angeline.french@srnl.doe.gov]

|

|

|

Listening to the Music of Exotics

|

Alex Dzierba, Jefferson Lab Visiting Fellow |

As a professor of physics at Indiana University, Alex Dzierba's name graces over 100 articles in the scientific literature; but his most unusual achievement may be a contribution to music.

In a 2004 distinguished faculty lecture at Indiana University, Dzierba discussed his work on the GlueX project at DOE's Jefferson Lab. GlueX is an experiment to probe the strong force by producing exotic mesons, particles built of two quarks held together by an excited "flux tube" of gluons.

Don Freund, a music professor at Indiana, was so impressed by Dzierba's talk that he composed a piece of music on the subject, "Exotic Particles and the Confinement of Quarks - A Subatomic Fantasy for Wind Ensemble." The piece was performed by music school students at the university in February 2005. "I'm one of the few physicists in the world with music written for his experiment," Dzierba says.

Dzierba landed at Jefferson Lab through a collaboration on two experiments at DOE's Fermilab. "One was an early bubble chamber experiment to look at the interaction of high-energy protons, and the other was similar but used an electronic version of the bubble chamber, which was an early precursor of our current GlueX work," Dzierba explains. "Since we will need the 12 GeV Upgrade [for GlueX}, my position at [Jefferson Lab] now is to work with the Director and his staff on that project."

Dzierba, his 16-year-old son, and his wife of 20 years, Linda, have recently taken up SCUBA diving as a family. "[It's] a wonderful enhancement to our existing hobby of photography," Dzierba says.

Pictures from his last trip line the walls of his Jefferson Lab office. When he's not working or snapping pictures of fish in the Caribbean, Dzierba also enjoys woodworking on a 16-acre farm his family shares with several horses.

Submitted by DOE's Jefferson Lab

|

|