- Number 300 |

- November 23, 2009

Aluminum hydride work a boost for energy storage

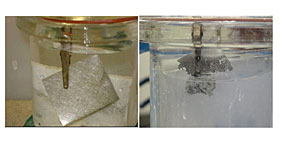

Aluminum electrode before (left)

and

after reaction

(right) in NaAlH4/THF.

Recent achievements at DOE's Savannah River National Laboratory with aluminum hydride, a high capacity hydrogen storage material, are not only expected to accelerate the development of a whole class of storage materials, but also have far reaching applications in areas spanning energy technology and synthetic chemistry.

The SRNL team, supported by the DOE Office of Energy Efficiency and Renewable Energy, has developed a novel closed cycle for producing aluminum hydride, also known as alane, that potentially offers a cost-effective method of regenerating the hydrogen-storing material in a way that allows it to repeatedly release and recharge its hydrogen. In this process, the hydride is made via an electrochemical method, and the starting material is regenerated directly with hydrogen.

In conjunction with this research, the SRNL team discovered novel ways to facilitate separation and formation of aluminum hydride that also apply to the formation of other complex metal hydrides and have the potential to cost-effectively regenerate other high capacity hydrogen storage materials. The SRNL results are expected to accelerate the development of a whole class of similar materials needed for hydrogen, batteries and other energy storage applications.

In addition, this work will significantly impact other fields including those of thin films, adduct based syntheses, and the recycling and regeneration of other materials.

[Angeline French, 803.725.2854,

Angeline.French@srs.gov]