- Number 335 |

- April 18, 2011

Palladium sorbents remove contaminants from syngas

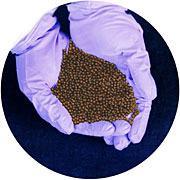

Palladium-based

sorbent beads

Many sorbents have been demonstrated for near-ambient temperature removal of mercury from natural gas and syngas, and for removal of mercury from flue gas at temperatures up to 350°F. However, few sorbents have been shown to remove mercury, arsenic, and selenium from high-temperature syngas. The National Energy Technology Laboratory’s palladium sorbents, which received an R&D 100 award in 2008, have been licensed for this application by Johnson Matthey. Southern Company has tested a 10-pound bed of the palladium sorbents in a slipstream of sour fuel gas at their Wilsonville Pilot Facility. The sorbent was exposed to the syngas for 718 hours at temperatures of 500-550°F. The syngas entering and exiting the sorbent reactor was periodically monitored for mercury, arsenic, and selenium. The used sorbent was also analyzed for mercury, arsenic and selenium. The palladium sorbent removed nearly 100% of the mercury, arsenic, and selenium present within the syngas, with no breakthrough of contaminants observed. This was the fourth and most challenging long-term exposure of the palladium to slipstreams of syngas at this pilot facility, and Johnson Matthey, delighted with the results, is planning a fifth long-term test for May 2011. In each case, the sorbent has removed nearly all of the trace contaminants, and these are outstanding results for multi-pollutant control. The work is timely, given EPA’s March 16, 2011, announcement of impending regulations for mercury and arsenic emissions from coal-utilizing facilities.

In a related study, researchers at DOE’s NETL recently investigated how the dispersion of palladium in NETL’s award-winning sorbents affects their ability to capture contaminants. The study showed that palladium dispersion determines its contact interaction with the support medium, which in turn affects susceptibility to sulfur poisoning. That poisoning can suppress or promote capture of different elements, depending on the contaminant. Therefore, tradeoffs must be considered when choosing a preparation method for the supported-palladium sorbents. In the design of adsorption beds, one could potentially use sorbents with different configurations of palladium on the support to optimize performance. This research was recently published in Fuel, Vol. 90, 2011, pp 1992-1998.

[Linda Morton, 304.285.4543

Linda.morton@netl.doe.gov]