- Number 375 |

- November 5, 2012

High-tech tools tackle wind farm performance

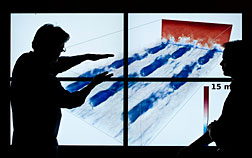

NREL's Steve Hammond, director of the

Computational Science Center, and

Kenny Gruchalla, senior scientist, discuss a

3D model of wind plant aerodynamics that

shows low-velocity wakes and the

resulting impact on downstream turbines.

Credit: Dennis Schroeder

From a distance, a wind farm can seem almost placid, turbines turning slowly, steadily, churning out electricity. But there's more to it than meets the eye.

The wind, though it can seem consistent, often has varying degrees of turbulence that impact wind turbine performance. Heating and cooling change the wind over the course of the day. A wind farm's turbines interact in ways that reduce performance and add to structural loads on the turbines, increasing maintenance costs and the overall cost of wind energy.

Researchers at DOE's National Renewable Energy Laboratory (NREL) are learning how to better understand these issues and are working toward effective solutions for the wind industry. Their goal is to maximize turbine performance and minimize structural loads, which will ultimately result in lower-cost wind energy. Toward that goal, NREL researchers are leveraging the lab's supercomputing resources and have developed high-tech modeling and simulation capabilities.

Wake turbulence is a type of instability in the wind flow and is the result of wind flowing through the rotor of a wind turbine. Its effects and how they impact wind turbine and plant performance have not been well understood. To better understand these issues and move toward effective solutions, NREL researchers have developed sophisticated simulation tools to perform large-eddy simulation models that are designed to predict the performance of large wind plants with greater accuracy than any previous models.

Wind plant developers have used design tools going back to the 1980s, which are generally effective for basic optimization of the layout of a wind farm. However, none have been able to simulate with consistent accuracy how wakes propagate and how wind turbines interact with one another.

"Previous models were very simple and don't capture a lot of the physics — how the atmosphere behaves and how wind turbines respond to changing conditions in the field," said Pat Moriarty, senior engineer at NREL's National Wind Technology Center.

Good models need good data. Data from operating wind farms provides validation for the models. So the project has been collecting data from offshore and onshore wind farms in both Europe and the United States to compare to the simulations. The backbone of this new modeling capability is the high-performance computing resources that run the simulations.

Researchers are currently using RedMesa, NREL's most powerful high-performance computing system, located at DOE's Sandia National Laboratories and managed in collaboration with Sandia. NREL will be adding additional high-performance computing capability in the next year with a new supercomputer on the lab's Golden, Colorado, campus. The supercomputer in NREL's new Energy Systems Integration Facility (ESIF) will be petaflop in scale (a petaflop is 1,000 teraflops) and will be the fastest computer system in the world dedicated to renewable energy and energy efficiency technologies.

One anticipated outcome of this enhanced simulation and modeling capability is improved understanding by wind plant developers of how to lay out their projects to achieve maximum performance from individual turbines. Issues to consider include placement of turbines in a wind farm, spacing between turbines, and how terrain and other location-specific conditions might impact turbine performance.

"We are trying to get a better handle on the physics of what is actually going on within the wind farm. All these issues affect performance, and that is the industry's greatest concern," Moriarty said. "This makes sense because it impacts their costs.

Another benefit to using these tools is in the area of 'wind farm controls.' This concept — a hot topic of discussion in the industry today — involves looking at a wind farm as a total system rather than just a collection of wind turbines. It explores how to best operate that system in a manner that leads to maximum efficiency for the wind farm as a whole.

"Wind turbines are greedy," Moriarty said. "They will try to extract as much energy from the wind as possible without consideration for anything around them, such as other turbines in a wind farm. This is not necessarily the optimal way to operate a wind farm as a whole."

Studies have shown that if the front row of wind turbines extracts less energy from the wind in an array than the turbines would by themselves, more potential energy would be available for all turbines downstream. In this scenario, the total energy capture of the entire wind plant would be increased. Another consideration is the slight turning of upstream turbines to steer wakes away from downstream turbines, maximizing the efficiency of the other turbines around them.

NREL’s work will create a better understanding of wind farm performance and will allow wind developments to be designed to maximize performance through increased energy capture and reduced maintenance costs — all of which leads to lower-cost wind energy.

Learn more about NREL's wind energy research.[David Glickson, 303.275.4097,

david.glickson@nrel.gov]