- Number 412 |

- April 28, 2014

NREL working to clean air in fracking process

NREL working to clean air in fracking

process.

In the annals of impressive eating, there was The Cat That Swallowed the Canary and The Eggplant That Ate Chicago. Now, add The Microbe That Consumes the Methane.

A microbe capable of digesting methane could save countless tons of greenhouse gas from reaching the atmosphere during the hydraulic fracturing process. Hydraulic fracturing, also known as fracking, uses pressurized water to fracture rock to release natural gas. It's been a boon to local economies and a source of inexpensive fuels—but if nothing is done to capture the byproduct methane, which is typically flared in the air, it can also contribute heftily to greenhouse gases in the atmosphere.

Scientists and engineers at DOE's National Renewable Energy Laboratory (NREL) are working with colleagues at the University of Washington (UW), LanzaTech, and Johnson Matthey to develop microbes that convert the methane found in natural gas into liquid diesel fuel. If successful, the Biological Gas to Liquids (BioGTL) process could also lower our dependence on foreign oil.

The amount of natural gas simply flared or vented from oil wells globally is enormous—six trillion cubic feet, which adds up to tens of billions of dollars in lost potential revenue annually. This adds greatly to global greenhouse gas emissions because every molecule of methane vented to the atmosphere in the fracking process has the global-warming capacity of 20 molecules of carbon dioxide.

Backed by a $4.8-million Advanced Research Projects Agency – Energy (ARPA-E) award from the Energy Department, the scientists are making progress. The goal of the project is to transform the current landscape of the energy and raw materials markets by producing a scalable, low-cost, low-temperature, and low-environmental-impact way of converting that wasted methane into a transportation fuel.

The scientists chose a novel microbe, Methylomicrobium buryatense 5GB1, which is one of just a few bacteria that have a high natural potential for producing lipids (a good biological feedstock for hydrocarbon-based fuels) from any carbon source. Within that small subset, 5GB1 is a rare species that can use methane to produce lipids—the precursor to fuel.

Scientists from NREL, UW, and LanzaTech have already shown at laboratory scale that the unique microbe growing in a simple mineral medium supplemented with a salt and carbonate buffer can double in three hours—twice as fast as other methanotrophs. Even with the faster growth, the lipid content comes in at an impressive 17% to 22%.

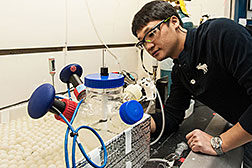

NREL's first major challenge was to demonstrate that the process can be done safely. In NREL's Integrated Biorefinery Research Facility, microbes consume the methane fed carefully into a fermenter, under the watchful eye of NREL Scientist Qiang Fei. "It's all about safety," Fei said, demonstrating how controls can combine methane and air in a safe way. He worked on the process for months, and in December, the continuous-feed system passed a safe work permit (SWP) protocol. That marks a big step on the road to getting commercial-scale fermenters to well sites.

UW researchers are focusing on genetically modifying the microbes to both increase the amount of membrane lipids and get the microorganism to produce non-phosphorous-based lipids that are more readily converted to fuels. At the same time, the United Kingdom-based Johnson Matthey team is working to convert the phospholipids into diesel fuel. Combining the super microbe with the best methane oxidation machinery at the fracking wells could result in a bumper harvest of lipids and create conditions that will yield even higher liquid fuel outputs.

New Zealand-based LanzaTech, a pioneer in waste-to-fuels technology, has signed on to take the bench-scale plan to the commercial level if it is successful.

Interest in the process is high. An Energy Department Bioenergy Technologies Office workshop in Chicago on turning natural gas into liquids drew a large crowd of important industry players. In addition, ARPA-E has recently awarded winners in its REMOTE (Reducing Emissions using Methanotrophic Organisms for Transportation Energy) solicitation to identify additional technologies to convert methane to fuels.

In its application to ARPA-E, the research team asserted that the process will simultaneously capture the energy lost by the stranded natural gas, provide a new source for liquid hydrocarbons, and mitigate greenhouse gas emissions—and the process will provide new jobs and new production capacity, while disrupting the current liquid fuel paradigm. That's because the Bio-GTL diesel product can use the existing pipelines at extraction sites to travel to refiners where it will undergo processing. It could prove useful for petrochemicals, too.

One more potentially transformative benefit: the single-cell protein produced as a byproduct has been explored for more than 20 years as a source of nutrition for both humans and animals.

Save enormous amounts of greenhouse gas; produce liquid diesel cheaply

and safely; create a source of nutrition for livestock and people.

Not bad for an organism too small to see.

Learn more about NREL's biomass research.

[Bill Scanlon, 303.275.4051,

william.scanlon@nrel.gov]