- Number 432 |

- February 9, 2015

Antireflective solar cells inspired by moths’ eyes

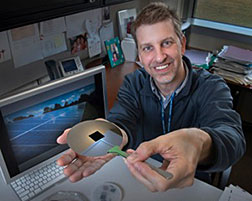

Chuck Black of the Center for Functional

Nanomaterials displays a nanotextured

square of silicon on top of an ordinary

silicon wafer. The nanotextured surface is

completely antireflective and could boost

the production of solar energy from silicon

solar cells.

Reducing the amount of sunlight that bounces off the surface of a solar cell helps maximize the conversion of sunlight to electricity. To achieve that goal, scientists at Brookhaven Lab etched a nanoscale texture onto silicon to create an antireflective surface as good as that achieved by multiple layers of thin-film coatings.

Their method, inspired by the antireflective textured surface of moths’ eyes, has potential for streamlining production and reducing manufacturing costs. It may also be applied to reduce glare from windows, provide radar camouflage for military equipment, and increase the brightness of light-emitting diodes.

One issue with traditional antireflection coatings, explained Charles Black, who led the research at the Brookhaven's Center for Functional Nanomaterials (CFN), is that each coating works best for a specific color of light and light oriented in a particular direction, so multiple layers are required. “We'd prefer to fully capture every color of the light spectrum, irrespective of the direction it comes from,” he said.

Moths’ eyes are a well-known example of such a multidirectional, broad-spectrum antireflective surface, helping moths to absorb light to see well at night and avoid any reflective glare that would alert predators to their presence. The secret is a textured pattern on the surface of their eyes made of many tiny "posts," each smaller than the wavelengths of light. Like a coating, these posts act to gradually change the refractive index between the air and the eye, cutting down on reflections that would be caused by a sudden shift at a flat interface.

The Brookhaven team recreated this patterned surface in silicon at even smaller sizes using methods of nanotechnology, incorporating methods commonly used in the manufacture of semiconductor electronic circuits. They masked the surface with a nanometer-scale self-assembled pattern and etched exposed parts with a plasma of reactive gases to leave a surface textured with tiny posts.

"Adding these nanotextures turned the normally shiny silicon surface absolutely black," said Atikur Rahman, a postdoctoral fellow working with Black at the CFN.

Full story.[Karen McNulty Walsh, 631.344.8350,

kmcnulty@bnl.gov]