| Research

|

|

||||||||||||||||||||||||

|

Check out the Office of Science's new Website.

|

Caught in the "Net"

|

|

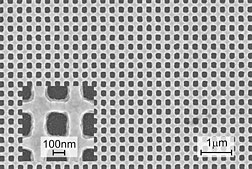

| Metamaterial micrograph: A micrograph shows details of the "fishnet" material. |

Metamaterials, also known as left-handed materials, are exotic, artificially created materials that refract light, or electromagnetic radiation, at a negative angle, opening a wide range of potential applications.

The challenge that Soukoulis and other scientists who work with metamaterials face is to fabricate them so that they refract light at ever-smaller wavelengths. The fishnet design, developed by Soukoulis and produced by nanostructure researchers Linden and Wegener has openings roughly 100 nanometers wide.

"We have fabricated for the first time a negative-index metamaterial with a refractive index of -0.6 at the red end of the visible spectrum, or a wavelength of 780 nanometers," says Soukoulis. "This is the smallest wavelength obtained so far."

While the silver used in the fishnet material is more resistant to energy loss when subjected to electromagnetic radiation than gold used in earlier materials, energy loss is a major limiting factor. The difficulties in manufacturing materials at such a small scale also limit the attempts to harness light at ever-smaller wavelengths.

"For applications to come within reach, several goals need to be achieved," Soukoulis notes. "We need to reduce losses by using crystalline metals and/or by introducing optically amplifying materials, develop three-dimensional rather than planar structures, create isotropic designs, and find ways of mass-producing large-area structures."Submitted by DOE's Ames Laboratory