|

Number 113, August 2009 |

Quick change

Quick change

With original retired, Spallation Neutron Source is now on its second mercury target

|

|

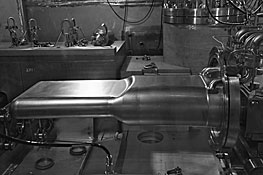

The original target just after it was retracted for removal. The entire operation, and all future change-outs, are done completely by remote operation. |

If you had placed a bet, based on conventional wisdom, on when the Spallation Neutron Source’s target change would occur, you probably would have lost.

SNS operators took advantage of a planned July-August maintenance outage to replace the original target, which had been in service since the SNS’s startup on April 28, 2006, having outlasted all expectations for its service life and never having actually failed.

“We were anticipating this operation as far back as the summer of 2008, and the fact is that the target received nearly twice the cumulative beam as its projected lifetime limit. In the meantime, neutron scientists have been reveling in the beam intensities the SNS is already providing,” says Thom Mason, who directed the SNS before becoming Laboratory director.

The SNS’s mercury target is the first of its kind. A proton beam generated by the SNS’s linear accelerator strikes the target 60 times per second with a force comparable to bursts from a large-caliber machine gun, “spalling” neutrons from the circulating mercury inside.

Eventually, the wear and tear of those forces were expected over time to damage the stainless steel of the target and render it unusable. The target is modular: It can be changed out whenever necessary. Some researchers estimated the first change would become necessary a year ago.

All of the changeout operations are done by remote operation—robotic manipulators controlled by trained technicians—because of radiation levels from normal operations of the target facility. In fact, all maintenance work performed in the SNS’s target bay will be done robotically throughout the life of the SNS.

One reason for the target’s longer than expected life could be that operators made the decision to run the SNS at lower power—and step up the SNS’s power more slowly—to give experiments that are already being conducted more stable beam time. Replacing the target during the maintenance outage avoids interruptions of experiments.

With a maximum design beam power of 1.4 megawatts, the SNS has been routinely operating at just under 500 kilowatts. Already the world’s most powerful neutron source, every time power is stepped up, a new record is established.

“Even at these power levels, our scientific users have been ecstatic with the results they are getting from their experiments,” says SNS Director Ian Anderson. In fact, the number of SNS users—288 at the end of June—has exceeded its goal of 260 for FY 2009, even with a quarter of the year left to go. For that matter, its older neutron source sibling, the High Flux Isotope Reactor, has also topped its user goal.

The SNS team has already operated the facility at close to megawatt levels. Recent tests verified that the linear accelerator and accumulator ring—two vital components that supply the proton beam pulses—are meeting and exceeding the 1.4 megawatt design criteria.

The replacement operation entails decoupling the target module and retracting it from the beam line area after draining the mercury— approximately 20 tons of it—from the vessel. Then the new module is put into place, returned to the target station and then refilled with the mercury. The entire process is performed with remote manipulators by operators working in a control room adjoining the target bay—a procedure that will be repeated each time the target is changed, which ultimately at full power could occur several times a year.

The old target will be studied to gauge how three years of proton bombardment have affected its materials.

Here's a backstage pass to the target changeout at the SNS target facility.—B.C. ![]()

Award-winning Artificial Retina Project has ORNL roots

Award-winning Artificial Retina Project has ORNL roots

|

Eli Greenbaum’s work with chlorophyll has been a factor in the Artificial Retina Project and in several spin-off technologies. |

The Artificial Retina Project’s R&D 100 Award, announced in July, is an added chapter in the partnership between an ORNL researcher and a leading expert on eye diseases that blossomed into an acclaimed project embraced by DOE and six of its national laboratories.

About a decade ago, Elias Greenbaum, UT-Battelle corporate fellow and leader of ORNL’s Molecular Bioscience & Biotechnology Research group, and Mark Humayun, of the University of Southern California’s Keck School of Medicine, founded DOE’s Artificial Retina program, aimed at restoration of sight to people who are blinded by age-related macular degeneration and retinitis pigmentosa.

“I listened to Mark’s presentation on artificial sight at a DARPA (Defense Advance Research Projects Agency) meeting and was impressed with his work. I thought, how can I get involved with this project?” says Eli. “One thing led to another. We started a pilot project collaboration that led to the Department of Energy’s Artificial Retina Project.”

DARPA’s aim was to develop cell-based systems that can identify human health risks in the battlefield and improve the performance of chemical and biological sensors and detectors. To Eli, it was also an opportunity to work with a great retina surgeon to provide partial sight to people who couldn’t see.

“Mark and I presented this idea to DOE program managers Drs. Dean Cole and Michael Viola, first as a pilot project and then as a full team proposal with multiple national laboratories, universities and Second Sight Medical Products as the CRADA (cooperative R&D agreement) partner,” Eli says.

Retinal diseases such as age-related macular degeneration and retinitis pigmentosa destroy vision by annihilating photo-receptor cells in the eye.

By 2002, a team led by Humayun at USC’s Doheny Eye Institute had effectively implanted an array containing 16 microelectrodes into the eye of a patient who had been blind for more than a half-century. Humayun successfully demonstrated that if retinal tissue is stimulated electrically using electrodes implanted in the eyes of legally blind patients, many of these people can perceive image patterns that mimic the effects of stimulation by light.

The Artificial Retina Project branched out beyond ORNL in the late 1990s when the Lawrence Livermore and Sandia national labs stepped forward to fabricate the electrode arrays and integrated circuit chips that are used to actuate the device.

The eventual research team, consisting of six DOE national laboratories, the Jet Propulsion Laboratory, four universities and private industry, developed a retinal device that replaces the eye’s lost light-gathering function of the rods and cones with a video camera.

“The vision isn’t 20-20, but it’s still something, and will improve with additional R&D.” |

“A miniature camera mounted in eyeglasses, or ‘pho-glasses,’ captures images and wirelessly sends the information to a microprocessor,” says Eli. “The data is converted to an electronic signal and transmits it to a receiver on the eye.”

The receiver is able to transmit signals through a tiny cable to the microelectrode array, emitting pulses. The artificial device bypasses defunct photoreceptor cells and transmits electrical signals straight to the retina’s remaining workable cells. The pulses travel to the optic nerve and finally to the brain, which perceives patterns of light and dark spots corresponding to the electrodes stimulated.

Patients learn to interpret these visual patterns. “The vision isn’t 20-20, but it’s still something, and will improve with additional R&D,” says Eli.

One trial patient equipped with a 60-electrode retinal implant describes on the Artificial Retina Project’s website how she looked up at a night sky and detected the full moon. As electrode technology progresses, sight would theoretically improve as more electrodes are added to the five-millimeter-square area on the retina than can receive the implants.

|

The more retinal implants, the better the vision would be for a patient. This simulation shows vision with (from left) 12 electrodes, 200, and more than 1000. |

And then there was the spinach factor. Eli and colleagues in the Chemical Sciences Division proposed replacing inactive photoreceptors in a patient’s retina with spinach, a special protein, which “generates a voltage in response to light that may prove able to trigger optical signals to the brain,” says Eli.

Eli and his coworkers, including Tanya Kuritz and Ida Lee, demonstrated that chlorophyll-containing proteins in spinach give off a small electrical voltage after capturing the energy of incoming photons of light. The same spinach protein could potentially be used to replace key, light-receiving parts of the human eye that have lost their ability to function.

One potential advantage to using the spinach protein would be a more efficient delivery of an electrical signal to the retina. In such a system, because the photo reception is directly into the eye, the camera-equipped glasses would not be necessary. It is also theoretically possible to implant many more proteins into the retinal area than the man-made electrodes, which could improve image resolution.

Eli describes the chlorophyll research as “inspired by Mark Humayun’s pioneering work.” Spin-off technologies include Aqua-Sentinel, a chem-bio sensing system that can help protect water supplies, and a treatment to prevent blindness from diabetes by supplying oxygen to blood-starved retinal tissues through retinal implants.

Currently, close to 30 people worldwide are testing the Artificial Retina Project implants in clinical trials. The artificial retina won’t be a cure-all for blindness: Eli points out that not all patients are alike, and some sufferers of the sight-robbing diseases are affected more severely than others. But he believes that the research project will eventually help many people to see again.

“Everyone is really doing great work,” says Eli. “It’s just a pleasure to go to the PI meetings and seeing some of the top notch people working on this important research.”

—Joanna Finney ![]()

Gary Baker latest Presidental Early Career winner

Gary Baker latest Presidental Early Career winner

|

Baker |

The Chemical Sciences Division’s Gary A. Baker is ORNL’s latest winner of the Presidential Early Career Award for Scientists and Engineers. Gary is one of 12 DOE scientists to receive the presidential award.

Gary is considered a leader in the relatively new field of ionic liquids, which have potential applications to emerging energy-related technologies including solar cells, lithium batteries, fuel cells and biomass processing.

“These extraordinarily gifted young scientists and engineers represent the best in our country,” President Barack Obama said. “With their talent, creativity, and dedication, I am confident that they will lead their fields in new breakthroughs and discoveries and help us use science and technology to lift up our nation and our world.”

Gary’s pioneering work in materials science and environmentally responsible chemistry has been recognized nationally and internationally. As author or co-author of over 100 publications with more than 2000 citations to his credit, he is a leading expert in the synthesis and application of green solvents, including supercritical fluids and ionic liquids, a new type of solvent.

“Gary Baker has the extremely rare ability to make outstanding contributions to numerous unrelated disciplines at the same time. This award is an indicator of the tremendous future Gary has in research at ORNL,” says ORNL Director Thom Mason.

His accomplishments include the invention of an innovative and simple method for producing frozen ionic liquid functional nanoparticles in variable sizes, the co-development of improved approaches for measuring properties of ionic liquids that are otherwise difficult to obtain, and the development of sensing methodologies with potential applications ranging from clinical glucose assays to biomass process monitoring. His design and synthesis of a series of bio-designer ionic liquids are expected to play a significant role in biomass processes, including the breakdown of cellulose into sugars for the production of ethanol, as well as biocatalysis and bioremediation.

Currently working in the Nanomaterials Chemistry group of ORNL’s Chemical Sciences Division, Gary joined ORNL in 2005 as a Eugene P. Wigner Fellow following a postdoctoral appointment at Los Alamos National Laboratory. He received his doctorate from the University at Buffalo, the State University of New York.

Gary’s awards and recognitions include the American Chemical Society Division of Analytical Chemistry Graduate Fellowship and the Frederick Reines Distinguished Postdoctoral Fellowship. Five of his papers have been featured on scientific journal covers.

He lives in Knoxville with his wife, Sheila, and two children, Kali and Kaden. ![]()

Lab staff’s generosity fills breach for United Way

Lab staff’s generosity fills breach for United Way

|

Campaign chair Edgar Lara-Curzio observes one of a United Way agency’s workshop participants as she assembles supplies for area craft stores. |

United Way campaign co-chairs Edgar Lara-Curzio and Kathy Carney and their cabinet have launched several activities to raise both awareness and funds for this year’s ORNL campaign, now under way.

The June 11 tour of United Way agencies introduced three organizations in Oak Ridge, including the Emory Valley Center. The center provides support and services to individuals with developmental disabilities, including the opportunity to earn a small income in the workshop.

“These tours were an eye-opening experience that allowed us to learn about the challenges these agencies are facing and to see, first hand, how our contributions are making a difference in the community,” Edgar says.

The June 23 campaign kick-off’s football throw and corn-bag toss, attended by UT football coach Lane Kiffin and members of his staff, raised nearly a combined $3,000. In July, the U.S. ITER office organized a catered Mexican lunch with donated themed gift baskets, raising almost $2,500. Adding in the $2,500 total from two book fairs brings the total as of July 31 to nearly $8,000.

Thursday, August 6, brought the International Festival, with 20 booths from countries around the globe and all ticket proceeds going to the United Way. Another August event is the third book fair of this campaign, August 18-20, on Main Street.

During August all employees are being encouraged to enroll in payroll deduction and, considering economic conditions, to seriously consider giving at the Leadership level.

This year retiree Tom Row, a former United Way campaign chair who was director of ORNL’s ES&H compliance and a senior assistant to former ORNL Director Al Trivelpiece, helped reach the more than 4,000 ORNL retirees to invite them to participate in this year’s campaign. “It has been exciting to start receiving checks and messages of support for the campaign within just a few days of mailing the invitation letters,” Edgar says.

As the campaign enters its final month, Edgar and Kathy point out that ORNL can be justifiably proud of its United Way record. In 2008, ORNL’s United Way donations increased by 10.2 percent, while U.S. charitable giving fell by the largest percentage in 50 years, almost six percent. The co-chairs are confident ORNL will meet this year’s ambitious goal of $925,000 committed through payroll deductions and other gifts.

The final total will be announced at the Leadership Givers Breakfast on Tuesday, September 22. ![]()

|

Another day, another record

Another day, another record

Just before its maintenance shutdown, researchers at the Spallation Neutron Source set a new world record by creating 155 trillion protons in a single pulse and delivering that pulse to the SNS mercury target.

The test exceeds the SNS design intensity of 150 trillion protons in a pulse. If pulses of this intensity were delivered to the SNS target at the design repetition rate of 60 pulses per second, it would provide a beam power of 1.5 megawatts, or 0.1 megawatts more than the facility's design beam power of 1.4 megawatts.

The tests, which were performed at a rate of less than one pulse per second, confirm that both the SNS’s accelerator and its accumulator ring are capable of reaching the design beam power, says Research Accelerator Division Director Stuart Henderson.—B.C.

Lab fleet adds hybrids

Lab fleet adds hybrids

|

Fleet manager

Kathye Settles

with some of the

new hybrid cars. |

ORNL has just taken another step in its sustainable campus campaign, this time again involving the Lab’s transportation services.

The latest additions to ORNL’s vehicle fleet are “tuxedo black” Ford Fusion and Chevy Malibu hybrids.

“These cars can get up to an impressive 41 miles per gallon,” says Kathye Settles of the Logistical Services Division.

The fairly luxurious and yet environmentally friendly automobiles will replace vehicles currently in the fleet. The Recovery Act-funded purchases have been approved because the new vehicles increase the fleet’s fuel efficiency. For that reason, more hybrid vehicles are on the way.

Examples of vehicles they replace include a 1993 Safari van with nearly 60,000 miles on it and three 1998 models.

“We’ll be able to tell how economically the new vehicles are performing from our fuel and vehicle mileage records,” Kathye says.

Eventually, ORNL will have 41 hybrids in its fleet in addition to more flex-fuel vehicles, which can run either gasoline or E-85

(85 percent ethanol).—J.F.

Students chalk out flight pattern

Students chalk out flight pattern

High school students from the Appalachian region are taking advantage of a once-in-a-lifetime opportunity to study with experienced researchers at ORNL—by drawing on a sidewalk with chalk.

|

ARC student Quinn Matney gains altitude. |

As part of the Appalachian Regional Commission Program, four students are studying air traffic control under Jim Rome, a former ORNL employee in the Fusion Energy and Computer Science & Mathematics divisions.

“We want to model airplanes in the airspace to make sure they don’t collide with each other,” Jim says. “We want to do this in a fail safe and a self-controlled manner.”

In a field experiment, students drew the “flight patterns” with chalk and used the concrete balls in the plaza outside the east end of the Research Office Building to represent interferences. Through simulation, Jim and his students are learning about modeling aircraft routes and how to pick appropriate courses so that the planes do not collide.

In addition to the ambitious nature of the simulation project, students are simultaneously learning how to use computer programming that they have no experience with. One of the ARC students, Quinn Matney, describes the challenge as two-fold.

“We are picking up programming while at the same time managing how to create a four-dimensional simulation of massive amounts of data,” Quinn says. “It’s quite difficult because none of us have any history with this topic, but it’s interesting at the same time.”

The ORNL Neutron Science TeraGrid Gateway sponsors the two-week summer session to encourage students to learn that computer programming is necessary to tackle most real-world problems.

Jim’s students came to ORNL from North Carolina, Kentucky, Tennessee and West Virginia.—E.M.

For those who would rather walk

For those who would rather walk

Lab staff members who like to go for the occasional stroll are about to get a new trail. One of the numerous construction projects scheduled for this fiscal year is a walking path along White Oak Creek that runs between the 6000 (Physics) and 7000 areas.

The route will also connect the main campus to the overflow parking lot at 7000, which has received some added use this summer owing to the closures of other lots and the summer influx of students and visiting staff.

“The path will be an eight-foot, blacktopped surface that crosses Melton Valley Access Road and winds its way down along the creek until it reaches the 6000 area,” says Facilities & Operations’ George Baber.

George says the trail should also be bicycle friendly.—B.C.

Reported by Joanna Finney, Emma Macmillan and Bill Cabage |

Eight: Lab has one of best years for R&D 100 Awards

Eight: Lab has one of best years for R&D 100 Awards

ORNL researchers and engineers have won eight R&D 100 Awards, presented each year by R&D Magazine in recognition of the year’s most significant technological innovations.

Now with 148, ORNL has won more R&D awards than any other DOE laboratory.

This year, researchers from ORNL received recognition for the following inventions.

Alumina-forming austenitic, dubbed AFA, stainless steels, invented and submitted by a team led by Michael Brady of the Materials Science & Technology Division.

AFA stainless steels boast an increased upper-temperature oxidation, or corrosion, limit that is 100 to 400 degrees Fahrenheit higher than that of conventional stainless steels. These new alloys deliver this superior oxidation resistance with high-temperature strengths approaching those of far more expensive nickel-based alloys without sacrificing the typical lower cost, formability and weldability of conventional stainless steels. These new alloys have applications ranging from gas turbines and power plants to chemical and petrochemical processing equipment.

The Artificial Retina Project, jointly submitted by Argonne National Laboratory, Lawrence Livermore National Laboratory, Los Alamos National Laboratory, Oak Ridge National Laboratory, Sandia National Laboratories, USC (Doheny Eye Institute), California Institute of Technology, North Carolina State University, the University of California at Santa Cruz and Second Sight Medical Products (see "Award-winning Artificial Retina Project has ORNL roots" story).

The artificial retina, a bio-electronic implant, enables patients with a severe form of retinal degeneration that causes blindness, the ability to recognize objects and navigate their environment. With the aid of the most current 60-pixel implant, patients can distinguish between light and dark. In order to be able to read large print and recognize faces, the implant must feature 1,000 pixels.

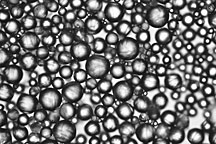

|

A close-up view of fire-resistive phase change material, one of this year’s eight R&D 100 Award winners. |

Fire-resistive phase change material, developed and submitted jointly by Jan Kosny and David Yarbrough of the Energy & Transportation Science Division; Tim Riazzi, Dan Davis and Dale Work of Microtek Laboratories; Doug Leuthold of Advanced Fiber Technology; and DOE’s Marc LaFrance.

This first-ever organic fire-resistive material when incorporated into conventional insulation can improve the heating and cooling efficiency in buildings. The new materials, composed of fatty-acid esters from sustainable plant and animal fats and blended with cellulose insulation, are the first phase change materials to fulfill all requirements in the U.S. flammability tests. The PCM adds thermal mass to buildings, thus generating heating and cooling energy savings of up to 25 percent in residential buildings. Temperature fluctuations are absorbed by the PCM-enhanced insulation and transferred to the environment later, resulting in energy savings.

Mass-Independent Kinetic-Energy-Reducing Inlet System for Mass Spectrometers, developed and submitted by Peter Reilly of the Chemical Sciences Division.

This technology permits high-resolution mass analysis of large, intact biological molecules without having to break them apart. With this spectrometer, the large biomolecular ions are captured in a trapping field while air is pumped away. Conventional spectrometers pump most of the ions away with the air, making them less sensitive. This mass spectrometer delivers much higher resolution in the high mass range compared with conventional spectrometers. For specific use in the medical field, the mass spectrometer can be developed to rapidly image a tumor and define the boundaries so the tumor can be most effectively treated.

MELCOT: Methodology for Estimating the Life of Power Line Conductor-Connector Systems Operating at High Temperatures, submitted by Jy-An John Wang of the Materials Science &Technology Division, Edgar Lara-Curzio of the Materials Science and Technology Division, Thomas King Jr. of the Energy Efficiency & Electricity Technologies Program, jointly with John Chan of the Electric Power Research Institute, Joe Graziano of the Tennessee Valley Authority and Tip Goodwin III of PBS&J.

This technology predicts the service life of conductor-connector systems. The splices connecting the conductor lines are literally the weak links in power transmission systems. With this new method of investigating performance and integrity of the power line systems, researchers can develop more durable and reliable systems for the electric power grid. Power grid operators can maintain power flow and prevent potential grid failures, and effectively reroute power distribution during emergency or natural disasters.

PulseForge 3100, jointly submitted by Stan Farnsworth of NovaCentrix and a team led by Chad Duty of the Materials Science & Technology Division.

The PulseForge 3100 uses rapid pulses of light for high-speed drying, curing, sintering or annealing high-temperature materials on plastic and paper, enabling inexpensive and flexible electronics. With the PulseForge 3100, high intensity flashlamps briefly heat inks and films to controlled high temperatures. The PulseForge and Pulse Thermal Processing systems provide a thousand-fold increase in the energy flux that is available to the surface of the processed part--cutting processing times to fractions of a second.

Superconducting “Wires” by Epitaxial Growth on SSIFFS, invented and submitted by a team led by Amit Goyal of the Materials Science & Technology Division.

Superconducting wires are flexible, single-crystal, high-temperature cables that enable high-performance advantages for electric power grid applications. These cables are different because they are round, rather than flat like conventional wires, which lowers heat loss and eliminates energy loss, making longer transmission lengths possible. Superconducting wires can carry five times more power than copper cables and are capable of long-distance power transmission, interconnecting entire continents and providing local energy storage. For a specific device or design, wires can be bundled into larger dimension wires of any shape.

Thermomagnetic processing technology, developed and jointly submitted by a large team from ORNL, Eaton Corporation, American Magnetics, Inc., and AJAX TOCCO Magnethermic Corporation. Gerard Ludtka and Gail Mackiewicz-Ludtka led the ORNL contingent.

Thermomagnetic processing technology could revolutionize the U.S. heat-treating industry with reduced energy and processing costs. This technology enhances materials performance with an 85-percent higher stretch capability strength, enabling lighter weight designs. Thermomagnetic processing technology uses superconducting magnets to cut down on energy use in the typical heat treat processing. High magnetic fields processing reduces residual stress (post-heat treating stress) and eliminates material phases, thus eliminating specialized thermal processing steps.—Emma Macmillan ![]()

FACEing the finale

FACEing the finale

ESD team collects data as Free-Air Carbon Experiment ends

After 12 years, an experiment focused on forest growth and climate change comes to an end, and researchers at ORNL are eager to collect and analyze data to see if their predictions match results.

With the DOE-sponsored free air carbon dioxide enrichment experiment, known as FACE, three plots of sweetgum trees were the control sites and two plots of sweetgums were exposed to increased carbon dioxide levels in the atmosphere at 550 parts per million, the concentration that is projected to occur in about 2050 if current trends continue. The atmospheric carbon dioxide concentration has been rising steadily because of the burning of fossil fuels and global land use change.

The effect of carbon dioxide on tree growth needs to be part of the overall calculation of climate change. |

Project leader Rich Norby of the Environmental Sciences Division describes the end of the experiment as bittersweet.

“In one sense, a project that I have been heavily involved in will no longer be an active experiment site,” Rich says. “On the other hand, I am looking forward to gathering the evidence and analyzing the materials to see if our hypotheses prove to be true.”

Already, researchers and students are sifting through the soil to measure the amount of fine roots and to examine them further. Smaller roots are significant points of study because they take up the majority of the water and nutrients and provide important clues to how forests will respond to higher carbon dioxide levels in the future.

This month, four to five trees per plot are being cut down for analysis. Throughout the experiment, researchers have measured the circumference and height, making projections about the weight of the tree, hypothesizing that increased carbon would lead to increased growth and thus a comparably higher mass. Now, researchers will actually be able to weigh the trees and compare the estimates to actual masses.

When considering how the forest stores carbon, trees are often assumed to store the most for the longest. Soil lives longer than trees, though, so some researchers see soil as a more obvious resource for storing carbon compared with wood.

Colleen Iversen, a post-doctoral researcher who wrote her dissertation on the FACE project, notes that the trees are cycling carbon through the forest ecosystem faster.

“We noticed that in the plots with increased carbon dioxide exposure, the trees are absorbing more carbon, but the trees are also releasing more carbon,” Colleen says. “What we are trying to understand is how much carbon is being cycled and how much is being stored.”

|

Rich Norby and Joanne Childs dig a soil pit at the FACE site. Much of the FACE action has been beneath the surface. |

Even before the experiment officially ended, one hypothesis was confirmed when researchers saw that an increase in carbon dioxide leads to an increase in roots growing deeper into the ground.

In previous studies, the focus has been on trees absorbing carbon dioxide, but the FACE experiment gives some attention to the fate of carbon in roots and soil.

“The carbon dioxide fertilization effect will not solve the problem of climate change,” Rich says. “With this research, though, it has become obvious that the effect of carbon dioxide on tree growth needs to be part of the overall calculation of climate change.”

The FACE project has resulted in more than scientific advances. FACE has been the subject of five theses and several dozen publications and has presented academic opportunities for numerous undergraduate and graduate students and post-doctoral researchers. FACE collaborators have included Argonne National Laboratory, Purdue University, University of Illinois at Chicago and University of New South Wales in Australia.

Ultimately, the results that come from comparing the control sites with the elevated carbon dioxide sites will help improve the computer models that make projections of future climate.—Emma Macmillan ![]()

ORNL research couples once-incompatible analysis techniques

ORNL research couples once-incompatible analysis techniques

ORNL researchers have been looking for ways to improve ambient surface sampling and ionization techniques, which are ways to analyze samples by mass spectrometry without having to first place them in a vacuum.

Gary Van Berkel, head of the Organic & Biological Mass Spectrometry group, and his colleagues have teamed up with the thin-layer chromatography companies Camag and Merck KGaA to combine mass spectrometry with planar separation, a technique called ambient surface sampling and ionization.

Thin-layer chromatography, or TLC, is often underestimated by chemists who are introduced to it in undergraduate organic chemistry labs as a simple and cheap low-resolution separation technique. Continued technical improvements over the years, however, have made TLC capable of high-performance, high-resolution separations.

However, TLC doesn’t interface well with identification techniques like mass spectrometry. Gary and his collaborators are working to change that: The ambient surface sampling and ionization techniques they have developed can be used with high-performance TLC. The direct surface sampling and analysis approach is beginning to be successful with larger biological molecules, such as peptides and proteins. High-performance TLC is less costly and time consuming than other methods, such as mass spectrometric analysis using electrophoretic gels.

Applications of the improved analytical method already include the fields of food safety and pharmaceuticals. For example, as reported in C&E News, in Zurich the technique is used to check food products for a toxic dye that is sometimes illegally put in spices to enhance their color. In Asia, where Artemisia annua plants are grown in large pots to produce artemisinin, a malaria treatment, high-performance TLC allows local labs to quickly identify when the artemisinin levels are highest.

High-performance TLC also allows multiple samples to be analyzed simultaneously, saving both time and resources.—Kathryn Baddorf ![]()

Reporting fraud, waste and abuse

Reporting fraud, waste and abuse

UT-Battelle is committed to performing its business activities with the highest standards of integrity, honesty and professional competency. As a UT-Battelle employee, you play an important role in our commitment to maintaining the highest business standards through your individual commitment to excellence.

Employees should refuse to engage in illegal or dangerous activities which the employee believes to be unsafe; to violate laws, rules or regulations; or to involve fraud, mismanagement, waste or abuse. Further, you have the responsibility to provide notice of inappropriate activities which threaten our joint dedication to integrity in the workplace and which may prevent us from meeting the expectations of DOE and our other customers. Fraud is a matter that is taken seriously. All allegations of fraudulent activities—p-card, travel, other purchasing activities, timecard abuse, etc.—are investigated by the Audit and Oversight Directorate who have trained certified fraud examiners on staff. When credible evidence is obtained, these matters are referred to the Office of Inspector General for review and possible criminal action.

A case of p-card fraud was recently settled that involved a former UT-Battelle employee. The individual was convicted in federal court and sentenced to four years probation, 20 hours of community service and payment of $3,605 in restitution.

For work performed under the DOE contract, UT-Battelle employees have a number of options for expressing concerns about activities they view as inappropriate on the job. We urge all employees to immediately report any information regarding possible fraud, waste, abuse, corruption or mismanagement relative to DOE programs, operations, funds or contracts. may provide information to Scott Branham in the ORNL Office of Audit and Oversight by calling 241-7614 or submitting a Fraud, Waste or Abuse Reporting form.

However, employees are not limited to reporting in this manner. Instead, or in addition, employees can use any of the following channels to report such information:

• Line management

• Steven Bonnett, Staff Concerns Coordinator (241-2255) or http://home.ornl.gov/programs/employee_concerns

• The Office of Inspector General (IG), 1-800-541-1625. The toll-free hotline number is operated 24 hours a day to permit immediate access by any employee.

Note that reports to the IG should be made within 24 hours of discovering information that suggests a violation has occurred. UT-Battelle notifies the IG of information it receives, but employees can make the report on their own if they choose to do so.

In all cases, UT-Battelle policy strictly prohibits any intimidation or retaliation for reporting such matters through any of these channels. This prohibition applies to UT-Battelle employees and employees of any subcontractor performing services for UT-Battelle. Anyone who observes or is subjected to intimidation or retaliation with regards to reporting fraud, waste, or abuse should immediately report the matter to Steven Bonnett at 241-2255.

All employees are required to work cooperatively with internal and external auditors and investigators. If you have any questions, please contact Scott Branham at 241-7614. ![]()

New Staff Members

New Staff Members

New Hires for July 2009

Dennis Duncan Earl (re-instatement), Jairus Burleson Hines and Ryan Alan Kerekes, Measurement Science & Systems Engr

Raghul Gunasekaran and Roselyne Dalanda Barreto, Center for Computational Sciences

Richard Dale Harvey, Global Initiatives Dir. (transfer)

Cole Richard Hexel and George Dongdong Jia, Chemical Sciences

Bryan Scott Johnson, Nuclear & Radiological Protection (transfer)

Katherine Ann Stusrud, Energy & Engineering Sciences Dir.

Elizabeth Mary Vacanti (transfer) and Hayley Joy Lamoureux, Contracts

Rosemary Elizabeth Walker, Thomas Jerome Wenning and Brandon Russell Langley, Energy & Transportation Science

Ting Xu, Steven Bradley Webb, Mark Stephen Lyttle and David Lee Cord, NScD Research Accelerator

April Dawn Andis and Tabitha Collins Mase (re-instatement), Human Resources Dir.

Dawn Marie Klingeman (re-instatement) and Thomas Scott Brettin, Biosciences

Gregory Robert Newkirk, Facilities Development

Joseph Nevada Williford, Information Technology Services

Yulong Xing, Computer Science and Mathematics

Kevin David Berry and Justin Robert Carmichael, NScD Neutron Facilities Development

Sylvia Shannon Davis, Business Services Dir.

Conrad Christopher Klepper (re-hire) and Arnold Lumsdaine, Fusion Energy

Maryjane E. Maelzer, US ITER Project Office

Philip Joseph Nugent and Olufemi Abayomi Omitaomu, Computational Sciences & Engineering

Tara Ruth Voit, Materials Science and Technology

Matthew Thomas Williford, Campus Support & Instrumentation

Donald Keith Newman, Facilities Management

ORNL People

ORNL People

The Materials S&T Division’s Amit Goyal has been elected a fellow of the World Technology Network, a global meeting ground and virtual think tank. He was also a finalist for the WTN’s materials award at its recent summit. Amit has also been chosen to receive the distinguished alumnus award for 2009 from his alma mater, the Indian Institute of Technology, at Kharagpur, India.

The Nuclear Science & Technology Division’s Julie Ezold has received the Patricia Bryant Leadership Award from the U.S. Women in Nuclear organization. The award was recently presented at the combined U.S. Women in Nuclear and Women in Nuclear Global conference in Washington. The leadership award was established to recognize U.S. WIN members who have made significant contributions and demonstrated leadership in the core values of U.S. WIN.

Chris Pickett, leader of the Safeguards & Security Technology group in the Global Nuclear Security Technology Division, has advanced to the grade of fellow in the Institute of Nuclear Materials Management. Fellow is the highest individual recognition by the INMM, with fewer than five percent of INMM membership holding the rank.

A climate visualization by Jamison Daniel and David Erickson recently received an OASCR (for Office of Advanced Scientific Computing Research) at the annual SciDAC ‘09 conference in San Francisco. Jamison works in the Center for Computational Sciences’ Scientific Computing group; David is with the Computational Earth Sciences group in the Computer Science & Mathematics Division. Their visualization describes the seasonal flux of carbon dioxide in the atmosphere over North America.

Jun Qu of the Materials Science & Technology Division is this year’s winner of the Outstanding Young Manufacturing Engineer Award from the Society of Manufacturing Engineers. Jun’s current research consists of advanced manufacturing, surface engineering and tribology. Having over 40 papers published in peer-reviewed journals and holding two patents, his technical achievements include wear-resistant nanocomposite surface processing, thermal drilling, oxygen-diffusion case-hardening for titanium, cylindrical wire electrical discharge machining and 3-D surface/curve matching.

The Physics Division’s Witold Nazarewicz received an honorary doctorate from University of the West of Scotland at its gradation ceremony on July 8 in Paisley, Scotland. Witek, who is joint faculty with the University of Tennessee and scientific director of the Holifield Radioactive Ion Beam Facility, was also recently appointed a visiting professor at UWS following a three-month Carnegie Centenary Professorship that he held last year. ![]()

Club ORNL

Club ORNL

|

Get the details and latest news on Club ORNL online via the ORNL home page and on ORNL Today. Retirees, to gain access to the ORNL home page, first register in XCAMS by going to http://www.ornl.gov/adm/clubornl_signup.shtml. After receiving your XCAMS account and Club ORNL membership, retirees can then go directly to https://www.ornl.gov/adm/clubornl. Ross Toedte, 574-1912, toedterj@ornl.gov, is the retiree point of contact.