|

Number 114, September 2009 |

Stellar stainless

Stellar stainless

ORNL’s CF8C-Plus stainless steel is proving unbeatable in the field

|

|

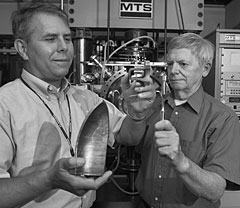

ORNL’s CF8C-Plus stainless steel proved the answer to Caterpillar’s particulate filter chambers, which are subject to high temperatures and rapid heating cycles that cause other materials to quickly fail. |

An award-winning stainless steel developed at ORNL is already proving itself in the field—and in the marketplace—as an all-purpose, heat-resistant alloy that can endure extreme temperature fluctuations and retain its properties. And it performs better than materials that cost up to seven times as much.

The CF8C-Plus cast stainless steel won the 2008 project of the year award from the Federal Laboratory Consortium’s Southeast Region. In May, ORNL and Caterpillar, one of the world’s leading heavy equipment makers, picked up the FLC’s 2009 national award for excellence in technology transfer.

DOE’s Vehicle Technologies Program supported the alloy’s development as a part of its program to develop advanced materials for energy efficient cars and trucks.

Caterpillar is using CF8C-Plus stainless steel in the regeneration systems for its ceramic particulate filters for diesel engines. The filters, which trap carbon particles from the exhaust gas, must be cleaned periodically. CF8C-Plus is used in the burner chamber ahead of the filters that initiates pyrolysis, breaking down the particulates. The carbon in the ceramic filter is then burned away, regenerating the filter.

The materials challenge for Caterpillar was to find a material that could withstand cycles of repeated rapid heating to very high temperatures without distorting or cracking. Ordinary commercial stainless steels are too weak when hot and can crack when they are cold, and thus cannot survive such rapid, repeated extreme temperature cycling over several years.

More than 450 tons of CF8C-Plus steel have been cast to make tens of thousands of parts, none of which have failed, even though some have been in service more than two and a half years.

“The temperature cycling rapidly degrades most materials,” says Phil Maziasz, the principal developer. “The high temperature causes oxides to form, and structural ‘creep’ (damaging high-temperature plastic deformation) occurs. Cooling then brings high-tensile residual stresses, which can cause a part to crack. Such cracks then open and grow during the next high temperature cycle and oxidize. Once started, these mechanisms can cause the parts to fail pretty quickly,” Phil says.

More than 450 tons of CF8C-Plus steel have been cast to make tens of thousands of parts, none of which have failed. |

In helping find a tough, strong material for Caterpillar’s regeneration systems, the Materials Science & Technology Division researcher took advantage of years of research in developing radiation-resistant materials for fission and fusion reactors. His development at ORNL of a new steel, which began with casting only one small batch of molten metal (called a “heat”), had moved up to commercial scale-up heats in only a year and a half.

“Reactors would make stainless steels and other materials brittle, mainly due to helium bubbles at grain boundaries, and swell due to void formation. Creep also causes voids during the final stages of ductile fracture. We did a great deal of electron microscopy of irradiated materials, which were very complex.

“We get the high performance without the high cost.” |

“We are the only people who really looked at this problem completely, sorted it out, and then came up with a systematic way of understanding our results,” Phil says.

“Once you have that understanding, you can then just look at other complex steels for other, no-radiation applications, like high- temperature creep and fatigue, and just dial in microstructures that stay good for a very long time,” he says. “Using the data base and following these rules is termed the ‘engineered microstructure’ method.”

With almost 30 years of experience behind him, Phil was able to make his first heat of steel at ORNL “just right.” With one specimen left, he ran a creep test at 850ºC that lasted two and a half years, due to its stable nano-carbides and nitrides.

|

Phil Maziasz (left) and Bob Swindeman with a sample of CF8C-Plus, which won an R&D100 Award in 2003 and a Federal Laboratory Consortium national award last year. |

Generally, nanostructures don’t form or stay stable at high temperatures because they don’t resist coarsening or dissolution.

For his development of the steel and the rapid commercialization, ORNL and Caterpillar won an R&D 100 award in 2003.

The CF8C-Plus stainless steel contains nitrogen, which adds strength similar to nickel, and manganese, which helps the steel dissolve more nitrogen. The manganese itself also dramatically improves work-hardening and enhances the metal’s fluidity, resulting in excellent properties for casting.

The good castability has made almost every CF8C-Plus part made, from 45-pound exhaust components to 6,700-pound gas-turbine casings, a first-time success, with no cracks, cavities or other casting defects.

Even more important to a manufacturer is the fact that the best high-temperature properties are found in the as-cast condition, so there is no need for additional heat treatments. CF8C-Plus has creep strength at 600-900ºC that compares well with nickel-based superalloys, like 625 and 617, which are five to seven times more costly, owing to the expensive alloying elements they contain, including nickel.

“It is easy to cast and easy to make things from, and the ‘cast-and-go’ aspect makes applications cheaper and easier,” Phil says. “We get the high performance without the high cost.”

Another huge advantage is that the CF8C-Plus cast stainless steel is very weldable. The weldability was tested and verified as part of the qualification process for a new heat-resistant cast alloy grade certification from ASTM, which was obtained in November 2008.

With its versatility, toughness and ability to outperform materials that are much more expensive, CF8C-Plus is headed toward another level of commercial applications. ORNL recently signed its second CRADA with Honeywell to test CF8C-Plus steel for turbocharger housings for both diesel and automotive engine applications.

Caterpillar is one of Honeywell’s largest customers, so co-developing CF8C-Plus with Caterpillar paid dividends with Honeywell, as well. Success with Honeywell Turbo Technologies should also lead to trials and applications with some of the world’s largest automakers.

ORNL has also had significant interest and collaboration in testing CF8C-Plus for gas-turbine engine components and other power generation applications. “Continued commercial trials and success will further expand opportunities for other applications and licensing,” Phil says.—B.C. ![]()

UT-Battelle gift supports OR Playhouse restoration

UT-Battelle gift supports OR Playhouse restoration

|

Our name in lights: Oak Ridge Playhouse is the latest of

UT-Battelle’s legacy investments in the community. |

UT-Battelle has announced a gift of $175,000 to the Oak Ridge Playhouse to help restore one of the oldest community theaters in the Southeast.

The gift, presented by ORNL Director Thom Mason before the August 28 Playhouse performance of “The Graduate,” is part of the Oak Ridge Playhouse “Next Stage” fundraising campaign.

The funds will be used for a new marquee and will help the Playhouse leverage the $2 million needed to renovate the theater’s aging facilities.

“The Playhouse is an important part of Oak Ridge’s history,” Thom says. “This gift will help preserve our history while supporting the arts in Oak Ridge.”

The Playhouse gift is the latest in a series of UT-Battelle’s “legacy investments” in the Oak Ridge region. The legacy investments, which include the renovation of Oak Ridge High School and new launch docks and a finish-line tower for the Oak Ridge Rowing Association, are efforts by UT-Battelle to fund projects that will bring value to the community for years to come.

David Bradshaw, co-chair of the Oak Ridge Playhouse capital campaign, said the facility originally was built as the Center Theatre movie house. Its conversion in 1957 to a live theatre venue included unique features—such as an underground tunnel for backstage access—that have endeared audiences and performers alike for decades.

“There are still people in Oak Ridge from the Manhattan Project era who went on their first date in that old movie house,” Bradshaw says. “The theatre productions are fantastic, but the facilities are deteriorating. We want to restore the physical condition of the building to equal the outstanding quality of the productions the public has grown accustomed to seeing there.”

Bradshaw said the renovations are separated into four distinct project areas: exterior and main entrance, lobby area, auditorium and stage, and first floor infrastructure and code.

Designers for the Playhouse renovation are McCarty Holsaple and McCarty, which designed the 2005 renovation of the historical Tennessee Theatre in downtown

Knoxville.

Established in 1943, Oak Ridge Playhouse is one of East Tennessee’s most active community theatres and one of the oldest in the Southeast, offering a wide variety of musicals, comedies, dramas and children’s plays. Located in Historic Jackson Square, the Playhouse facility includes a 344-seat auditorium, dressing rooms and rehearsal space, a costume rental shop and office space.

A volunteer organization that operates with a balanced budget, the Playhouse enjoys a strong reputation for outstanding theatrical production. Participation in the Playhouse is open to the community.—Mike Bradley ![]()

Singh, Kreykes named UT-Battelle Corporate Fellows

Singh, Kreykes named UT-Battelle Corporate Fellows

|

|

Singh |

Kreykes |

UT-Battelle has added two ORNL researchers to its list of UT-Battelle Corporate Fellows. David J. Singh and Jon A. Kreykes have been recognized for sustained outstanding achievements in their scientific and technical fields.

“The UT-Battelle Corporate Fellows represent significant influence in the scientific community and outstanding achievements in the delivery of critical technical missions. David Singh and Jon Kreykes certainly have demonstrated that impact,” says ORNL Director Thom Mason.

David Singh, of the Materials Science and Technology Division, is a condensed matter theorist who is internationally recognized for his contributions to the methodology for electronic structure calculations and in applications to diverse classes of materials. His work in condensed matter and materials physics, superconductivity, radiation detection and thermoelectric materials has resulted in growing programs that span the interface between basic and applied research.

With more than 300 scientific papers to his credit, David is a sought-after speaker at leading technical conferences. His honors include the 2008 UT-Battelle Director’s Award for Outstanding Individual Accomplishment in Science and Technology.

Jon Kreykes, of the Global Initiatives Directorate and currently assigned in Washington, D.C., was recognized for his far-reaching accomplishments on national security issues including nuclear weapons and nuclear materials proliferation. He regularly briefs senior U.S. government officials on national-security-related technical issues and provides direction and guidance to the Oak Ridge Field Intelligence Element, which he directed for five years.

Jon was the technical lead for one of the United States’ most celebrated nuclear nonproliferation efforts, Project Sapphire, which was headed by the Y-12 National Security Complex and removed nearly 600 kilograms of highly enriched uranium from Kazakhstan. His awards include the 2007 Secretary of Energy Achievement Award and a Director of National Intelligence Seal Medallion, also in 2007.—B.C. ![]()

Leadership Givers breakfast

to cap 2008 United Way drive

Leadership Givers breakfast

to cap 2008 United Way drive

|

Lara-Curzio |

The UT-Battelle United Way campaign concludes with a Leadership Givers breakfast on Tuesday, September 22, to highlight what is hoped will be another record-setting campaign.

Leadership Givers are defined as those who contribute at the highest level of giving according to their pay category, as follows.

• Exempt employees: 1.5 of your base salary or $1100 (i.e., an exempt employee who gives either 1.5% of their base salary or $1100 annually will be recognized as a Leadership Giver).

• Weekly salaried employees: Red Ribbon Givers, $250-$499; Blue Ribbon Givers, $500 or more.

• Bargaining unit employees: Silver Leader, $250-$499; Gold Leader, $500 or more.

Mintha Roach, CEO of the Knoxville Utilities Board and member of the United Way of Greater Knoxville board, is the featured speaker. Each Leadership Giver will receive a special gift and a 2009 Leadership Givers pin.

Items to be auctioned by local auctioneer “Bear” Stephenson include a football autographed by UT football coach Lane Kiffin, who kicked off the Lab’s campaign in June. All proceeds will benefit the United Way. Drawings for special prizes will include a pair of skybox seats at a UT home football game and a one-year parking pass for a space near the building where the winner works.

ORNL directorates will receive trophies for the highest combined percentage increase of contributing employees and Leadership Givers (for the directorate with less than 50 employees and the directorate with more than 50 employees). Also recognized will be ORNL retirees who have contributed to the ORNL campaign and the area’s United Way county directors and managers.

Finally, campaign chair Edgar Lara-Curzio will reveal the total received and pledged to the 2009 ORNL Campaign. ![]()

|

fueleconomy.gov cleared clunkers

fueleconomy.gov cleared clunkers

The “Cash for Clunkers” program has ended, which has both car dealers and the folks at the Center for Transportation Analysis breathing a little easier.

The center’s staff developed the fueleconomy.gov Website for DOE and the Environmental Protection Agency, and now maintains it. The site, which was already one of the most popular government sites on the Internet, saw its page views mushroom when the clunkers program started.

The reason, explains the Environmental Sciences Division’s Bo Saulsbury, is fueleconomy.gov has EPA fuel economy ratings for all cars and light duty trucks sold in the United States since 1985. It thus became the National Highway Transportation & Safety Administration’s standard reference for the dealers to base their rebates.

Dealers couldn’t cut a clunker deal unless the trade-in’s fuel economy was listed in fueleconomy.gov.

In some cases, there were gaps in the data. One minivan make was listed for 1993 and 1995, while the 1994 model, with a virtually identical power train, was omitted. For a ‘94 model owner, that was a deal killer.

“At one point we were getting 60 calls a day. We worked with the EPA to plug in any missing entries,” Bo says.

“Between May 18 and August 24 when the program ended, we answered over 7,000 emails from dealers, consumers and other interested parties,” says the center’s Stacy Davis. “Many wanted to know the fuel economy rating for their vehicle, or explanations for why their vehicle did not qualify. Others reported vehicles that were not in our database or identified concerns with the data. We notified the EPA of the data issues and they were able to provide us with additions and revisions for our Website, which we promptly posted.”

Meanwhile, the center’s Janet Hopson saw the website’s page views skyrocket, from 21 million in May to 162 million in July, when Cash for Clunkers was in full bloom. August was on a similar track up to the program’s end.

The surge in traffic nearly crashed the site’s server. Ultimately, however, fueleconomy.gov helped make the Clunkers program one of the most popular of the economic recovery measures.—B.C.

Beacon house looking sharp on Chestnut Ridge

Beacon house looking sharp on Chestnut Ridge

|

The refurbished beacon house now stands as a monument to early aviation. |

Just a few ridges behind the Spallation Neutron Source, a one-of-a-kind facility that provides the most intense pulsed neutron beams in the world, sits a relic that used to help pilots navigate across the country.

Built before ORNL was even a blueprint, a yellow metal shack with a black stripe around the middle guided pilots through the day and night in the 1930s. Formally known as the Airway Beacon Lighthouse, this 10-by-14-foot structure was part of the route that extended from Nashville to Knoxville, a section of the overall Transcontinental Airmail Route that stretched from Wyoming to New York (See Reporter No. 96).

Generations later, the Laboratory has invested in revitalizing this piece of air navigation history.

“In 2008, we initiated an effort to restore the beacon house back to its original specifications,” says Ann Bryant of the Facilities Management Division. “Due to its uniqueness and cultural relevance, the old structure was targeted for actions to return it to its former condition as part of the Laboratory’s responsibility to manage the historical legacy of the site.”

Every 10 miles, a beacon lighthouse built on a large yellow concrete arrow would direct pilots during the day while the beacon would take over at night when an arrow could not easily be seen.

Before, the beacon lighthouse resembled a rusty shanty that served no purpose, but with a fresh coat of paint it begs to be noticed among the forested area. Although empty inside, this station does not need fancy interior work to stand as a testament to original air navigation tactics.

“It’s amazing how a coat of paint, window treatments, a new door and some minor landscaping work can completely revitalize a historical relic,” Ann says. “As we build beautiful new facilities, we must continue to treasure the historic ones.”—Emma

Macmillan

|

Bethel Valley Road repeated its role as a racecourse for the Oak Ridge Velo Classic on August 22. This racer shows that even in bicycle events a good tongue-hold is paramount. | |

As H1N1 influenza looms, prevention could stem its spread

As H1N1 influenza looms, prevention could stem its spread

Health officials are expecting a busy flu season this year, particularly with the H1N1 influenza strain. Although the virus has not been confirmed in Laboratory staff members, one ill employee who had been exposed to someone with confirmed H1N1 virus was sent home in August.

This means that H1N1-strain influenza, also called “swine flu,” is most likely present in the community and poised to spread. Health officials are expecting an outbreak with the onset of cool weather. Preventive actions can reduce your chance of contracting and spreading this new and virulent strain.

|

Frequent hand washing is a simple and very effective way to prevent spreading and contracting seasonal lllnesses. |

If you get sick with influenza-like symptoms such as 100º F. or higher fever, stay home from work and contact your personal physician. Limit contact with others to keep from infecting them. However, if you live in areas where 2009 H1N1 influenza cases have been identified or have been exposed to travelers returning from affected areas and become ill with influenza-like symptoms including fever, body aches, runny nose, sore throat, nausea or vomiting, or diarrhea, contact your health care provider. Your health care provider or public health department will determine whether influenza testing or treatment is needed, depending upon the circumstances.

Everyday actions can help prevent the spread of germs that cause respiratory illnesses like influenza. These simple steps can protect your health and prevent the spread of flu and most respiratory ailments:

• Wash your hands often with soap and water, especially after you cough or sneeze. Alcohol-based hand sanitizers are also effective.

• Cover your nose and mouth with a tissue when you cough or sneeze. Throw the tissue in the trash after you use it.

• Avoid touching your eyes, nose or mouth. Germs spread that way.

• Avoid close contact with sick people. Influenza is thought to spread mainly person-to-person through coughing or sneezing of infected people.

Staff members planning foreign travel should contact Health Services as part of the Foreign Travel approval process. Health Services will notify you of any safety and health issues that you should be aware of before traveling.

It is never a bad idea to plan for how to deal with a challenging situation, such as a potential flu pandemic for you and your family. The Pandemic Flu Planning Checklist for Families & Individuals provides a helpful basic tool for this task. This and more mitigation topics are available at www.pandemicflu.gov.

ORNL management is coordinating with local DOE officials on preparedness activities. ORNL has a Pandemic Infectious Disease Preparedness Plan that is maintained continuously. Useful information links are at the Lab’s Pandemic Response Website, home.ornl.gov/general/pandemic.

Employees with further questions can also refer to the at www.cdc.gov. Questions about ORNL’s preparedness activities can be directed to Carol Scott, ESH&Q Operations Manager, at 241-1550, e-mail scottch@ornl.gov. ![]()

GEM students, mentors tackle summer projects

GEM students, mentors tackle summer projects

Six students participated at ORNL this summer in the GEM program, or National Consortium for Graduate Degrees for Minorities in Engineering and Science, Inc. GEM’s mission is to increase the participation of underrepresented groups (African Americans, American Indians, and Hispanic Americans) at the master’s and doctoral levels in engineering and science.

|

From left: ETSD Director Johney Green Jr., Calvin Phelps, Brian Letzen, Aaron Curry, Jerome Taylor, Elliott Ortiz-Soto, Steven Walker and Patricia Glenn. |

Calvin Phelps (master’s fellow), is pursuing his degree at North Carolina State University in aerospace engineering. Calvin worked with Burak Ozpineci in the Power & Engineering Systems group (Energy & Transportation Science Division), where he contributed to designing a grid-connected solar inverter using silicon carbide power devices.

Brian Letzen (master’s fellow), is pursuing his degree at John Hopkins University in biomedical engineering. Brian worked with Justin Baba in the Monolithic Systems Develop group (Measurement Science & Systems Engineering Division), collecting and analyzing experimental data for the validation of a newly developed optical properties system.

Aaron Curry (master’s fellow), is pursuing his degree at North Carolina Agricultural & Technical State University in electrical engineering. Aaron worked with Moonis Ally in the Whole-Building &Community Integration group (ETSD), where he provided research support on solid state lighting and solar photovoltaic materials.

Jerome Taylor (master’s fellow), is pursuing hisdegree at the University of Tennessee in mechanical engineering. Jerome worked with Bruce Bunting in the Fuels, Engines & Emissions Research group (ETSD), supporting fuel chemistry and fuel surrogates activities.

Elliott Ortiz-Soto (Ph.D. fellow), is pursuing his degree in mechanical engineering at the University of Michigan. Elliott worked with Robert Wagner in the Fuels, Engines & Emissions Research group (ETSD), where he assisted in modeling spark-assisted HCCI combustion modes with a focus on cyclic and cylinder dispersion.

Steven Walker (master’s fellow), is pursuing his degree at Georgia Institute of Technology in mechanical engineering. Steven worked with Melissa Lapsa in the Whole-Building & Community Integration group (ETSD) on current projects relating to thin-film photovoltaic material systems, as well as solid state lighting material systems.

Patricia Glenn (Nuclear Engineering Science Laboratory Synthesis program) is pursuing her degree at the University of Tennessee in nuclear engineering. Patricia worked with Saed Mirzadeh in the Isotope Development group (Nuclear Science & Technology Division), where she contributed to a project utilizing the ORNL High Flux Isotope Reactor to produce medical radioisotopes. ![]()

Bio-inspired photovoltaic materials research seeks new photoconversion energy source

Bio-inspired photovoltaic materials research seeks new photoconversion energy source

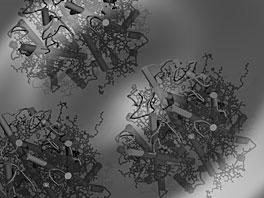

|

Light Harvesting Complex II, the protein responsible for light capture in plants, is visualized in a polymer membraner. |

Natural photosynthetic systems—plants—have developed a complex machinery for the efficient conversion of sunlight to chemical energy, which to the present day has not been matched by man-made technologies. A group of ORNL researchers is investigating ways to mimic these exquisite molecular architectures to develop synthetic bio-inspired systems for the conversion of solar energy to electricity and fuels.

The ultimate goal, says principle investigator Hugh O’Neill of the Chemical Sciences Division, is to convert solar energy into electricity or fuels, thereby developing a competitive energy source, which is one of the key challenges outlined by the DOE’s 2005 Basic Energy Sciences Workshop report, “Basic Research Needs for Solar Energy Utilization.”

The researchers hope the results of the work will lay the foundation for future photovoltaic devices, which combine the elements of naturally occurring photosynthetic systems of plants with functional polymers whose morphology can be engineered to take on desired forms.

The interdisciplinary research team consists of Hugh O’Neill, Kunlun Hong, William Heller, Dmitriy Smolensky and Mateus Cardoso and Xiang Yu, collectively of the Chemical Sciences Division, Cener for Nanophase Materials Sciences and Center for Structural Molecular Biology, and Bernard Kippelen of the Georgia Institute of Technology.

The researchers use the High Flux Isotope Reactor’s Bio-SANS (CG-3) instrument for their small-angle neutron scattering, or SANS, studies. Bio-SANS, the cornerstone of ORNL’s Center for Structural Molecular Biology, is optimized for investigating the structure and dynamics of proteins, polymers, colloids and viruses.

Much of the team’s research involves studies of Light Harvesting Complex II (LHC II), a protein complex that is responsible for light capture in plants. SANS experiments were performed with LHC II in detergent solutions containing mixtures of hydrogenated and deuterated water. Control of the D2O concentration allows the visualization of the protein and detergent separately, as well as the sample as a whole, through the application of contrast variation methods.

At the H2O-D2O mixture where the detergent is invisible (~15%), researchers could see the scattering profile of the protein, without any significant contribution by the detergent. This study showed that the protein was in its native trimeric state and provides preliminary data for studying the interaction of the protein with synthetic polymer systems. The group plans to use the Bio-SANS instrument for follow-on structural analysis studies of the polymer-protein systems.

“This fundamental research takes inspiration from nature, utilizing LHC II, and combines it with precision polymer synthesis to produce new photosynthetic systems that will potentially have properties that exceed current biosystems,” says Phil Britt, Chemical Sciences Division director. “These studies will lay the foundation for understanding how the macromolecular structure—or more precisely the three-dimensional orientation of molecules in space—leads to the conversion of light into electricity and how to design new more efficient biohybrid systems.”

In future work, the researchers will extend their research by developing synthetic versions of LHC II to replace the natural protein. It is envisioned that synthetic analogues of LHC II could be directly intregated into electroactive block copolymers to produce a self-assembled photovoltaic structure in a configuration that will respond optimally to light. —Agatha

Bardoel ![]()

MTSU leads

new HFIR instrument team

MTSU leads

new HFIR instrument team

ORNL has collaborated with a team of research institutions to bring a state-of-the art-instrument for the neutron analysis of advanced materials to the High Flux Isotope Reactor.

Middle Tennessee State University, North Carolina State University and Hauptman-Woodward Medical Research Institute have obtained a single-crystal neutron diffractometer, called IMAGINE, through the National Science Foundation and the American Recovery and Reinvestment Act.

MTSU principal investigator Tibor S. Koritsanszky and colleague Flora Meilleur from North Carolina State, in collaboration with Robert Blessing from HWMRI and ORNL’s Bryan Chakoumakos, will use IMAGINE to analyze light atom positions in materials of interest across the diverse fields of chemistry, structural biology, pharmacology, condensed-matter physics, nano-structured materials and in the environmental, biomedical and geological sciences.

“This diffractometer will fill a gap in U.S. neutron diffraction capabilities, since no similar capability or instrumentation is currently available at a neutron reactor source in the United States,” Koritsanszky says.

The instrument will take advantage of neutrons produced by HFIR, the nation’s most powerful research reactor and the benefactor of a recent upgrade with new beam lines and instruments.

IMAGINE will be placed on a beam line with a cold neutron source, in which neutrons are chilled to reduce their energy and make them more useful for analyzing materials’ properties at longer microscopic lengths.

Single-crystal neutron crystallography allows accurate and precise determination of the full three-dimensional structure of a molecule and provides accurate information about the spatial arrangement of molecules relative to the neighboring molecules. It is especially useful for determining the position of hydrogen atoms, which the related technique of X-ray diffraction cannot do as well.

“Because of the HFIR’s high intensity of neutrons, we will be more able to study the structure of compounds that produce relatively small crystals,” Koritsanszky says. “These studies will have an impact in a number of areas ranging from systems of medium-size molecules of biological interest to large molecules containing metal organic frameworks useful in materials research.

“This instrument will be an integral part

of teaching as well as research,” he

says.—B.C. ![]()

Hodge appointed to staff concerns post

Hodge appointed to staff concerns post

|

Hodge |

William “Bill” Hodge has been appointed staff concerns coordinator. In addition to his new rotational assignment within the Audit & Oversight Directorate, Bill will continue to perform information technology audits, investigations and other assessments.

Staff members are encouraged to work within their line organizations toward resolving concerns. However, when concerns or issues arise that are not solvable through the normal line-organization channels or functional areas or when staff are uncomfortable with other channels, they may contact the ORNL concerns coordinator.

Bill brings over 15 years of operational experience from companies including US Bank/Nova and PricewaterhouseCoopers. He holds a B.B.A. in business and a masters of accountancy from East Tennessee State University as well as an A.A.S. in computer science. He is a certified information systems auditor as well as a certified information systems security professional. During his tenure at ORNL, Bill has conducted a variety of information system-related audits and has assisted in the investigation of various employee concerns.

Bill succeeds Steven Bonnett, also of Audit & Oversight. The ORNL Concerns Program Website is located at home.ornl.gov/programs/employee_concerns/. ![]()

Boys and Girls Club

seeks volunteer mentors

Boys and Girls Club

seeks volunteer mentors

The Boys and Girls Club of Oak Ridge offers a number of educational after-school activities, 3:30-5 p.m. each weekday. Mentors for students are a big need.

Subjects cover reading, math, science, English & Spanish, computer skills and history for elementary grades and middle school.

“ORNL staff members and retirees are uniquely qualified and could provide some badly needed assistance at the Boys & Girls Club off Jefferson Circle in Oak Ridge,” says Dave Reichle, retired Lab associate director.

Any staff member or retiree willing to help should contact the Oak Ridge Boys and Girls Club at (865) 482-4433 or orbcgc.education@gmail.com. Those responding should ask for the “education director” or the “executive director.” They will appreciate your help, Dave says. ![]()

UT-Battelle named mentor of year

UT-Battelle named mentor of year

|

From left: Brenda DeGraffenreid, DOE Office of Small and Disadvantaged Business Utilization; Keith Joy, director of Small Business Programs; Jerome Hicks, Contracts Division director; and Marsha Daigle, U.S. Small Business Administration. |

UT-Battelle, LLC, has been named

the winner of the 2008 DOE Mentor of the Year Award. The award was presented recently at DOE’s 10th Annual Small Business Conference in Long Beach, Calif. Accepting the award on behalf of ORNL were Keith Joy, Director of Small Business Programs, and Jerome Hicks, Contracts Division Director.

The Lab contractor received the award in recognition of the ORNL Mentor-Protégé Program, which is designed to enhance the capabilities of small businesses to perform contracts and subcontracts for ORNL, other DOE laboratories and federal agencies. The DOE Mentor of the Year award recognizes the efforts of a DOE mentor that have exceeded the requirements of their mentor-protégé agreement and have, thus, enhanced the protégé’s capabilities and ability to successfully compete for federal contracts.

ORNL has seven small business protégés for the FY 2006-2008 program, the largest number for any DOE science laboratory. The Laboratory also has mentor-protégé agreements with two Historically Black Colleges and Universities—Morehouse College and Jackson State University.

UT-Battelle is a national leader in the support of the small business community. The small business program has won the 2006 DOE Small Business Innovation Award and the 2007 SBA Francis Perkins Vanguard Award, and the program’s director, Keith Joy, was named 2007 Small Business Programs Manager of the Year. ![]()

New Staff

Members

New Staff

Members

August 2009

Adam Michael Aaron and Deokjung Lee, Nuclear Science & Technology

Richard Todd Bolden, Facilities Management

Travis Carl Burnette, Office of Chief Information Officer

Terri Denise Cleveland, Shirley Jean Marion (transfer) and Stanton Allen Fears (re-hire), Contracts

Sebastien Nicolas Xavier Dryepondt, Raymond Robert Unocic, Kinga Angelika Unocic and David Lee Wood III, Materials Science & Technology

Rachael Lea Jackson (re-instatement) and Edward Harold Adair, Information Technology Services

Alexander Kisliuk and Alexei P. Sokolov, Chemical Sciences

Mikhael Richard Loo and Mary Ann McGarvey, Global Nuclear Security Technology

Christopher Thomas Rathgeb, Kelly Marie Testa, Anil Meerasa Cheriyadat and Angela Gail Trott, Computational Sciences & Engineering

Richard Craig Robertson, Global Initiatives Dir.

Bradley Wade Settlemyer, Paul Richard Charles Kent, Jonathan Daniel Dobson and Cory David Hauck, Computer Science & Mathematics

Brian Scott Bevins, Curtis Maurice Cash, Jr., David Andrew Elmore, Timothy Clay Gibby and Rhonda Sue Kyker, Campus Support & Instrumentation

Pamela Vaneese Byrd, Energy & Engineering Sciences Dir.

Ethan Nathaniel Coffey, Bogdan Vacaliuc and Ivan Valerevich Vlassiouk, Measurement Science & Systems Engr

David E. Graham, Biosciences

Carri Johnston Hilson, Bryan Jeffrey Hilson (re-hire), Suzanne Marie Tice and Tacie Roman Hall, Human Resources

John Stephen Moss and Jeffrey Wade Saunders (re-hire), NScD Research Accelerator

Jeffrey David Munk, Michael Ralf Starke, Jeffrey Marvin Bielicki and Sachin Uttamrao Nimbalkar, Energy & Transportation Science

Steve Frank Ventura, Legal Dir.

Benjamin Jacob Glover, Nonreactor Nuclear Facilities

Xianglin Ke, NScD Neutron Scattering Science

Wesley Michael Pelle, NScD Neutron Facilities Development

Judah Lee Wilkins, Quality Systems and Services

Retiree Waters’ plane models displayed around country

Retiree Waters’ plane models displayed around country

|

Gene Waters and his son display a 1/16-scale Boeing 777 they built for the McGhee Tyson Airport Authority. |

Gene Waters knows how to retire. In his work life, he was a science technologist in the old Analytical Chemistry Division at ORNL. In his private life, he is a superb builder of model airplanes, a hobby that began at age eight.

Don’t think small planes made of balsa wood and tissue paper. Think huge hand-crafted models of modern materials that are exact replicas of real planes. They have wing spans of 10 feet or more. They are so realistic that, from a few feet away, they look like the real thing.

Gene has built gliders, radio-controlled planes, war birds, seaplanes, and airliners. His models for overhead display are displayed all round the country: Chicago, Washington State and Alaska.

His most recent project, which took a year to complete, is a scale model Boeing 777. It has a wingspan of 14 feet, a fuselage of 13.5 feet, and a weight of 80 pounds. It is spectacular. You can see it at the Anderson County Career and Technical Center in Clinton. —Judy Kibbe

If you have a story of interest about an ORNL retiree, send it to Judy Kibbe, kandjkibbe@comcast.net. ![]()