|

| Number 20, October 2000 |

|

Revitalization: Secretary, governor unveil ORNL’s future look

Revitalization: Secretary, governor unveil ORNL’s future look

|

| (From left) Energy Secretary Bill Richardson, Gov. Don Sundquist, Rep. Zach Wamp and Rep. Bob Clement share a light moment after unveiling ORNL's modernization plan. |

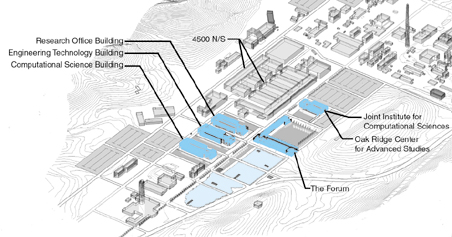

ORNL can look forward to new facilities and major renovations as part of a revitalization plan announced by Energy Secretary Bill Richardson on September 11.

“For more than a half-century, Oak Ridge National Laboratory has been one of the world’s leading scientific institutions,” Richardson told ORNL employees. “Modernization of the Lab today will ensure that it continues in its leadership role for another generation.”

The Energy Secretary came to ORNL to announce the five-year plan to modernize the Lab’s facilities. The plan includes the construction of 11 major facilities and the renovation of several others over the next five years. More than half the buildings at ORNL were built during and immediately following World War II.

He was joined before the crowd of about 800 by Gov. Don Sundquist, Rep. Zach Wamp -Chattanooga), Rep. Bob Clement (D-Nashville), and a host of federal, state and local officials.

“In a highly competitive research community, it takes world-class facilities to attract world-class scientists,” said ORNL Director Bill Madia. “This modernization plan represents the largest construction effort on the ORNL site since the Manhattan Project in 1943.”

One of the plan’s most innovative features involves the long-term transfer of DOE land on the present ORNL site, making possible construction of seven new facilities funded by the state and Battelle. Four of the 11 facilities would be funded by the state of Tennessee, and three would be funded by Battelle, which has partnered with the University of Tennessee to manage ORNL. The partnership among DOE, the state and the private sector is the first of its kind in the nation and a potential model for other national laboratories.

In addition to upgrading the Lab’s research capabilities, the modernization plan also will reduce operating costs, improve safety and reduce energy consumption at ORNL. When construction and renovation are completed in 2006, ORNL will have replaced 1.8 million square feet of expensive and outdated space with about 600,000 square feet of modern, energy-efficient buildings.

Elements of the modernization plan include a new mouse genomics facility that will help bring the human genome project to life, new chemistry facilities, a new facility for computational sciences, and a facility to house the Oak Ridge Center for Advanced Studies.

The federal government’s funding of the modernization plan for ORNL is subject to Congressional approval.—Billy Stair

New, upgraded facilities aimed at ‘world class’ Lab

New, upgraded facilities aimed at ‘world class’ Lab

New buildings—part of the Lab revitalization plan—will change the face of ORNL when they become a reality. The most exciting part of the building campaign may be what’s going inside those structures.

Preliminary plans call for a new cafeteria and public assembly area, plus office buildings that will house researchers and support staff and possibly some new user centers.

Older facilities will be revamped into new lab space.

Tim Myrick, who is heading the Lab’s facilities improvement projects, says that although plans are very subject to change over the next few years, a most certain outcome will be that ORNL will shed some of its institutional grayness and look more like a world-class science facility to those who arrive.

“The first thing visitors will come to is being called the ‘Forum’ building,” Tim says. “The Forum will be the place for public interaction at ORNL. It will include a visitor reception area, the new cafeteria and a 250-seat auditorium to replace Wigner Auditorium in Building 4500-North. It will also have breakout rooms, so it will be a really nice, usable place for a conference setting.”

The Forum, which is a DOE line item project, will extend from where the current Building 5002 sits now toward Bethel Valley Road. It will be preceded, however, by the first of a set of three privately funded research buildings in what is currently the east parking lot. Slated to move into those are staff members from the Lab’s Engineering Technology Division, probably in the first to be built, and from the Computer Science and Mathematics and Computational Physics and Engineering divisions in the second. A third building will house various research and support staff offices.

| "We're not plowing up a lot of new ground for these facilities. |

Separate pools of water extending west from the current Swan Pond will front those three buildings. Those ponds might be used as thermal sources for heat pumps. Energy efficiency and environmental concerns, in fact, are being figured into the new building plans.

“We’ll investigate the most energy efficient technologies for the buildings, which is where the idea for using the ponds for heat pumps might work out,” Tim says, adding that most of the new buildings go on land that has already been developed in some way.

“We’re not plowing up a lot of new ground for these facilities. We didn’t go up into the side of the hill, and we haven’t crossed Bethel Valley Road. Most of these buildings are going into brownfields, which have previously been parking lots, retainment ponds, burial sites or old buildings. We intend to reuse an old burial ground and remediated ponds for parking.” (A cleaned up pond was capped for such a purpose several years ago at Y-12.)

To the west of the Forum, between the current flagpole parking lot and main portal, a state-funded building to house the Oak Ridge Center for Advanced Studies and Joint Institute for Computational Studies is sited. That area is currently home to several nice hardwoods, and Myrick says they’ll try to preserve them.

In fact, trees are a significant part of the plan. Architectural designs call for a tree-lined boulevard to run from the Forum building east to the 6000 area and beyond. Lab staff members may get the opportunity to donate trees—most likely the state tree, the tulip poplar—to the cause.

|

On the west side, new facilities that include the Functional Genomics Laboratory (the new Mouse House), the adjacent Joint Institute for Biological Sciences and the Center for Biological Sciences (on the current site of Building 1000) will, as Tim envisions, “make the Marilyn Lloyd Research Complex bloom as a research center.”

In between, after environmental restoration projects are completed in the center of the X-10 site, plant services facilities currently housed in the 7000 area could move to the more central environs.

Existing structures aren’t being left out of the plans. Buildings 4500-North and South are to be renovated, a corridor at a time, with offices replaced with new lab space and outdated and inefficient utilities replaced and upgraded. It’s been pointed out since the UT-Battelle team came in that old, inefficient buildings are eating up a lot of money, and upgrading and replacing them are expected to add up to major cost savings.

Administrative offices and the research library are likely to remain in Building 4500-North, Tim says, but many offices in the center of the building will be converted to lab space.

For those who have just read with alarm that their current parking space is about to be occupied by a new structure, Tim assures that parking areas will be upgraded and expanded where the 6026 trailers are now, as well as the north parking and flag-pole lots. Over time, employees will likely be able to park closer to their buildings, reducing what Tim calls the “mall” parking lot feel.

The Forum, east-side research office buildings and new Mouse House are part of a first phase of construction that could see the first buildings—the privately funded research buildings—open by 2002, winding up in 2006. Phase two, which includes the Center for Biological Science, runs until 2011. Plans for even more structures are included in a third phase that runs from 2012 to whenever.

One thing’s for sure—in just a few short years the approaches to ORNL are going to look much different.—B.C.

Amazing graphite foam keeps turning industry heads

Amazing graphite foam keeps turning industry heads

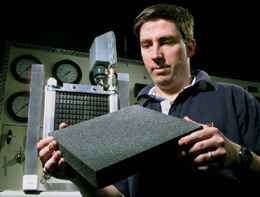

Just a few short years ago ORNL’s James Klett discovered a new carbon-based material—a graphite foam—that has amazing heat transfer properties. If you hold a puck of graphite foam in your hand and place an ice cube on it, the cube melts from your body heat as if it were on a hot griddle

Three years and a commercial license to Poco Graphite, Inc., later, the Metals and Ceramics Division researcher has an R&D 100 award and a box of press kits to respond to industry inquiries. PocoFoam, as it’s now trademarked, has attracted lots of attention from industries interested in applying it to a number of uses. A mention in Business Week brought in 800 inquiries. It even attracted interest from within the Lab.

| James Klett holds a block of graphite foam. A prototype radiator that uses the foam is in the background. |

|

“Bob DeVault in Energy Division’s Buildings Technology Center read about it and called. The result of that call is a radiator for a natural-gas-fired

V-8 engine that drives an industrial heat pump. The radiator transfers heat very efficiently to the air, and since this air is hotter than with a normal radiator, it can be used to regenerate the desiccant that removes humidity from building air more efficiently.”

James says the radiator is a test model to provide data for a more refined model to be built later. But it paints a picture of what graphite foam offers to a world increasingly interested in conserving energy and using it as efficiently as possible. ORNL wants to build on its strength in materials research; James’s graphite foam is a good example of why materials technology is so important to energy research.

“Graphite foam is as thermally conductive as aluminum at one-fifth the weight. It has a very high surface-area-to-weight ratio and a high heat transfer coefficient. This interests engineers and designers because products that use energy wage an ongoing battle with heat,” he says.

“The hotter something runs, the shorter the life. Increasing the temperature of an electronic component by 20°F will typically reduce its service life by half. At the same time, decreasing the operating temperature of a computer chip by 20 degrees increases its life and reliability by a factor of two.”

And, as James points out, about two-thirds of all energy consumed is wasted through heat. Components incorporating Poco-Foam could carry that damaging heat away from electronics—advanced heat “sinks”—and would weigh less because the material weighs less. And less weight in itself would result in energy saved.

James’s M&C team replaced a standard finned-aluminum heat sink from a microprocessor with a similar graphite foam sink. The foam heat sink, mainly because of its higher surface area, outperformed the aluminum sink even though it weighed only a fifth as much. When James ground the fins off the foam heat sink, the foam still dissipated heat on par with the much heavier aluminum sink.

Consider that if you’re designing a spacecraft with a very strict payload limit.

The weight and temperature factors also have attracted the interest of the racing industry. Graphite foam radiators would not only reduce the weight of the car, but also their high thermal efficiency would enable designers to place the radiator away from the front of the vehicle, which could enable more aerodynamic designs. A number of NASCAR Winston Cup teams have visited James’s lab to see for themselves. James has also received inquiries from several Formula One racing teams.

Enhancing radiator efficiency could also make a difference in design of more conventional vehicles such as semi trucks, which lose as much of 25 percent of their energy efficiency overcoming wind resistance. Streamlined trucks of the future, with their radiators in places other than the front, could resemble rocket ships more than boxes.

Graphite foam car radiators could also eliminate auto overheating in heavy city traffic. The graphite-foam-designed radiators have outperformed aluminum radiators by 30 percent. “However, this was a test case and we still need to determine the durability of such a design,” says James.

Another goal is to recycle the wasted heat. Heat exchangers, James says, are not very efficient. “The air temperature exchange from car radiators is not very much,” he says. “Improve that exchange—take more heat from the system—and you can use that heat to run other systems and do more work with it. The principle applies to a number of processes, similar to the way heat recovered through the BTC’s heat exchanger regenerates the desiccants.”

James notes that significant research lies ahead on a material in its infancy. “There is so much that we have found that this can be used for, such as a basis for replacing carbon fibers in composites, sound absorption, anodes for lithium ion batteries and firewall protection.”

“This is a truly revolutionary material that will find uses in many applications,” says Patrick Davis of the Office of Transportation Technologies, which currently funds materials research on carbon foam at ORNL. “Specifically, we believe carbon foam is an enabling technology that will solve critical heat rejection problems we must overcome before fuel-cell and advanced power electronics technologies can be introduced into automobiles.”

Robert Kirk, manager of DOE’s Office of Advanced Automotive Technology observes, “When I review the list of recurring areas of automotive interest, I see the thermally conductive carbon foam most frequently. I am pleased with this high level of industry interest since it provides convincing evidence that our research funds are well placed and effectively utilized.”

Over the past couple of years James has amazed scores of people with his foam and ice demonstration—there’s usually not a dry hand in the house by the time he’s done. His first try at an R&D 100 hit paydirt this year, one of ORNL’s three winners. That probably means folks will keep calling.

“A fellow from an electronics firm just called from out of the blue today,” he says.

There goes another press kit.—B.C.

SNS funding: Full request

SNS funding: Full request

Several Oak Ridge projects received good news from Congress just before this issue went to press. The House and Senate conference committee approved $278 million for the Spallation Neutron Source—that’s the full amount of the administration’s request for FY 2001. It’s also more than the $241 million approved by the Senate and much more than the $119 million passed by the House. The legislation, after a final vote, will ultimately by signed into law by the President.

The SNS’s prospects were boosted by funds added at the last minute to energy and water project legislation, which funds many science projects. Supporters are crediting the concerted efforts of the six participating laboratories—ORNL, Argonne, Brookhaven, Berkeley, Los Alamos and Jefferson Lab—and the science community in working for the project. The Tennessee legislative delegation has also been unified in touting construction of the United States’ first major science facility in several decades.

The neutron science facility has a total price tag of $1.4 billion and a projected completion date of 2006.

The conference committee also approved $2.5 million for a new Mouse House, which keeps plans for an

The conference committee also approved $2.5 million for a new Mouse House, which keeps plans for an new facility, to be located on the west end of the ORNL campus, on schedule with funds for concept and design.—B.C.

Lab officials hope volunteers satisfy staff reductions

Lab officials hope volunteers satisfy staff reductions

ORNL has initiated a voluntary reduction-in-force program as the first phase of a staff reduction effort aimed at lowering the Lab’s cost of doing business. Officials are hoping that enough volunteers come forward to make the second phase—an involuntary RIF—unnecessary or minimal.

ORNL Director Bill Madia announced the staff reduction program September 22. In an e-mail to ORNL staff members, Madia said the Lab’s “reduction of indirect costs, combined with program funding reductions, is expected to affect roughly 300 employees.”

Several dozen applied for the VRIF package shortly after it was announced. The VRIF window was to close October 6. Applicants have until November 10 to withdraw from the VRIF plan.

If needed, an involuntary RIF will occur in late November or early December, after VRIF numbers are assessed and federal R&D budgets are finalized.

“Reducing the cost of doing business at ORNL and giving our customers more research and development for each dollar they spend at the Laboratory have been consistent messages since UT-Battelle assumed responsibility in April,” Madia said. “Becoming a value leader among DOE laboratories is critically important for securing ORNL’s future.”

Madia has stated the goal of moving ORNL into the lower third of national labs in terms of cost of doing business. Currently, ORNL is one of the most expensive.

Madia cited ORNL’s effort to reduce indirect costs by $20 million in the fiscal year 2001 budget, plus a loss of $25 million in directly funded work, mostly in environmental management programs, as necessitating the work force reduction.

The Lab director also pointed out, however, that some overhead rates for FY 2001 would be lower than the current year’s.

“The two most significant overhead rates, G&A (general and administrative) and research division organization burden, will be lower than those for FY00,” he said. “For the first time in many years the cost of doing business at ORNL will actually go down. This improvement in our rate structure is a signal of our commitment to put ORNL back on the path of business growth and financial stability.”

Madia said in July that efforts to reduce the Lab’s indirect costs by $30 million over two years, with $20

Madia said in July that efforts to reduce the Lab’s indirect costs by $30 million over two years, with $20 million coming out in FY 2001, would likely require a reduction in force. The remaining $10 million is expected to be saved through operational improvements.—B.C.

Bismuth-213 processing for cancer research begins

Bismuth-213 processing for cancer research begins

Processing has begun at ORNL that will give researchers sufficient quantities of bismuth-213 to test its effectiveness as a cancer treatment. The short-lived isotope is derived in a new process from ORNL’s stored supply of uranium-233.

The initiative, announced by Energy Secretary Bill Richardson, will make the isotope available for research treatments of conditions such as acute myeloid leukemia, lung cancer and large tumors. Cancer research using bismuth-213 is being conducted at Memorial Sloan-Kettering Cancer Center in New York, the Fred Hutchinson Center Research Center in Seattle, the National Institutes of Health and several other worldwide institutions, including ORNL.

In the collaborative effort among the Chemical Technology, Chemical and Analytical Sciences and Life Sciences divisions, thorium-229 is separated from uranium-233 and added to the Lab’s inventory. When bismuth-213 is ordered, actinium-225, which has a half-life of up to six weeks, will be separated and purified from the thorium-229 and shipped. Research centers will use an actinium generator to process the bismuth-213, which because of its 45-minute half-life must be done on-site.

The effort provides a beneficial use of the uranium-233 stored at ORNL, the result of reactor and other research activities in past decades. The current program is expect to run for one to two years. —Marty Goolsby

Blood drive starts Oct. 12

Blood drive starts Oct. 12

ORNL’s next blood drive is set for Thursday, October 12 through Tuesday, October 17 at Building 1503. Hours are 8 a.m. to 4 p.m. except Friday, when they will open at 7 a.m. Retirees who wish to volunteer to call Ernie Wilson at 922-0246.

Top gun stresses technological edge

Top gun stresses technological edge |

| Gen. Shelton tours the Lab, guided by his host, Associate Lab Director for National Security Frank Akers. |

Shelton told a Lab audience of nearly 300 that U.S. military forces must be armed with the greatest technology to remain the strongest and most capable in the world.

That’s partly because U.S. forces aren’t the largest. Shelton said that the U.S. Army ranks fourth in the world in size, behind China, Russia and North Korea. So the “technological edge” is crucial.

Shelton added that there is no dividing line between a soldier and a scientist. By working together, the two groups can make America stronger. “For over 50 years, this great Laboratory has served America,” Shelton said. “And you continue to play a crucial part today.”

ORNL’s ISMS program clears bar

ORNL’s ISMS program clears bar

ORNL’s Integrated Safety Management System program has been deemed “adequate” by DOE-ORO. Last month’s two-week ISMS Phase II verification at ORNL culminated with an out-brief by David Allen, the DOE-ORO team leader. The Plant and Equipment Division must complete one action before DOE’s official declaration of “readiness.”

DOE praised the ORNL work force’s “commitment to the ISM principles.” David Milan, manager for Management Systems Integration, expressed his appreciation to the Chemical Technology and Plant and Equipment divisions for their teamwork efforts that resulted in the successful review.

“The teamwork exhibited by all involved in this success was exceptional,” David said. “The Laboratory should be proud of the collective efforts of the various divisions, as well as support and guidance from our colleagues at PNNL. Our challenge, of course, is to continue toward the mark of excellence in ESH&Q by refining and enhancing the ISMS implementation tools developed over the past two years and by implementing those actions identified in our Laboratory agenda.”

Honest co-workers mean no losers

Honest co-workers mean no losers

The fellow who searched the world for an honest person could have saved a lot of time by visiting ORNL first. Engineering’s Warren Thomas says he recently arrived home minus $110 he had when he left work. A hasty search of the Building 1000 area, where his office is, turned up nothing, so he figured it was gone forever.

“The next morning I thought it might be worthwhile to ask around the nearby offices to find out if anyone had seen my lost bills,” Warren says. “To my astonishment Cathy Higdon, who sits down the hall from me, said that three $20 bills had been found yesterday by the west door by two different individuals.”

They were Robert Martin and Tyler Denton. Warren, Cathy and Ronnie Jackson searched again in the parking lot, where Ronnie found the rest—two twenties and a ten, “slightly wet from being outside all night, but otherwise none the worse for the wear.”

Warren counts five people (Tim Myrick held the cash until the owner was found) who helped return the cash to its “careless but appreciative” owner.

“These people demonstrated honesty and integrity in a time when we do not hear about such traits very often,” Warren says. “It is an honor to work around people of such high character and ORNL is a better place for having these individuals here.”

| —Reported by Bill Cabage and Fred Strohl |

|

ORNL’s history is on display ORNL’s history is on displayBuilding 4500-North’s flagpole lobby is now home to the History of ORNL exhibit, the culmination of a two-year project sponsored by the Laboratory Advocacy Group. The exhibit, which has benefited from the time and efforts of a number of Lab staff members, features a series of posters summarizing significant events and achievements decade-by-decade, a display of artifacts and a touch-screen video that makes available to viewers interesting vignettes from ORNL’s past and information about the Lab at the present. “We have had input from all the former Lab directors and many current and former scientists,” says the Lab Advocacy Group’s Barbara Ashdown. If you’re coming through the flagpole lobby, build a good chunk of time into your trip to check out the exhibit. |

Days of past glory: The Oak Ridge Research Reactor once had a royal heyday

Days of past glory: The Oak Ridge Research Reactor once had a royal heyday

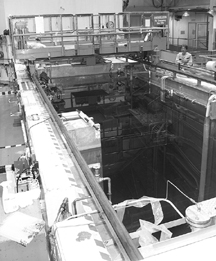

Hardly anyone goes there anymore, but it used to be the biggest ticket in town.

The Oak Ridge Research Reactor is like a magnificent but disused old department store. Once a top draw for scientists, politicians and even kings and queens, the ORR closed its doors 13 years ago. Its famous next-door neighbor, the Graphite Reactor, has been converted into a popular museum. What’s in store for the ORR is probably the wrecking ball.

Back in the fifties, when people used to go “downtown”—in this case, “Isotope Alley” in the center of the X-10 site—the ORR began an illustrious 30-year career as the most powerful research reactor in the world, 100 times more powerful than its historic predecessor across the parking lot. The 20-megawatt reactor’s neutron flux was bested in 1958 only by the Materials Testing Reactor in Idaho.

|

Among the famous who visited the ORR were (clockwise from top) Sen. and future President John F. Kennedy and wife Jacqueline in 1959, shown with Director Emeritus Alvin Weinberg and the late Sen. Albert Gore (right); Queen Frederika of Greece in 1958 (shown with Weinberg); and the late King Hussein of Jordan in 1958. |

|

|

Scientists flocked to ORNL to use the ORR’s powerful beam lines to perform research that helped give the phrase “atoms for peace” true meaning. Physicists Arthur Snell, Cleland Johnson and Frances Pleasonton confirmed the electron-neutrino theory of nuclear beta decay at the ORR, which led to the refinement of recoil mass spectrometry techniques. Harvard’s Norman Ramsey collaborated with ORNL researchers to refine his neutron spectrometer, which, along with other research into the characteristics of protons and neutrons, earned him a Nobel Prize for Physics in 1989.

Wallace Koehler, Mike Wilkinson, Ralph Moon, Ray Child, William Dress, Bob Peelle and a host of other researchers well known in the ORNL community performed groundbreaking research at the ORR in the fields of neutron scattering, nuclear fuel development and reactor engineering.

|

| Artie Butler (upper right) helps maintain the ORR's reactor pool. Keeping the demineralized water level up is one of the chief costs of maintaining the facility. |

Except for a brief period toward the end of its service life, the ORR used highly enriched uranium for fuel. The reactor core, immersed in a 30-foot-deep tank of water that still serves as shielding, emitted the magical blue Cerenkov glow that made it an attraction for VIP visitors to ORNL.

That dance card includes, in 1959, Sen. (and soon-to-be presidential candidate) John F. Kennedy and future First Lady Jacqueline; Sen. and future President Lyndon Johnson in 1959; and Vice President Hubert Humphrey and future President Gerald Ford, both in 1965. Royal figures stopping by during Oak Ridge visits included Queen Frederika of Greece in 1958 (who is often mistaken for Britain’s Queen Elizabeth in photos), King Leopold of Belgium in 1957 and King Adulyadej of Thailand in 1960. Jordan’s late King Hussein visited as a young monarch of 23 in 1959. Other world leaders, either then or later, who visited include Indian ambassador Indira Nehru in 1963, who went on to become Prime Minister Indira Ghandi, and leaders of Afghanistan and Northern Nigeria.

To Lab management during the late ’50s and early ’60s, it must have seemed like “king for a day” at times.

Then, like all good things, it all came to an end on March 26, 1987. The ORR operated for 10,537 days, producing 5,788, 267 megawatt hours of thermal energy. As is typical for many center-city attractions, it had been superceded by a spiffy, more powerful facility located out in the suburbs—the High Flux Isotope Reactor, situated across the ridge near the Molten Salt Reactor Experiment.

Corporate Fellow Herb Mook did neutron scattering research in the ORR for a few years before moving his work across the ridge to HFIR, which went on line in 1966. He says there was little comparison in working with the 20-megawatt ORR and the 100-megawatt HFIR.

“We did a lot of good science at the ORR, but HFIR was so much better,” Herb says. “HFIR was the reason I came here.”

These days the ORR has the musty feel of a house that hasn’t been lived in for a while. One of its few frequenters is Bratati Lynn. Bratati, who recently assumed facility manager duties for the ORR and the Graphite Reactor, watches over the reactor as it is being “characterized” for upcoming decontamination and decommissioning activities. The ORR is now a clean-up site. Bratati is an employee of Bechtel Jacobs Company, the Environmental Management program contractor.

Except for the fact that in summer it gets pretty hot inside the non-air-conditioned building, Bratati says she’s enjoying her “interesting” assignment.

“We’re doing everything remotely with video cameras in the reactor pools,” Bratati says.

Bratati, along with Facility Operations Manager Arnie Butler and Doug Byrum, watch after the demineralized water levels (minerals in normal tap water would corrode pool components) and perform routine checks on the dormant reactor facility’s well being.

|

| Facility Manager Bratati Lynn demonstrates a scale model of the ORR. In its day, the reactor was one of the most powerful research reactors in the world.. |

The facility currently has a category III rating, which means there is “potential for significant localized consequences” (in this case, radiation dose) if the reactor pool lost its water. The level of demineralized water in the reactor pool has to be maintained to shield the highly activated materials in the pool.

Some of the most radioactive materials in the reactor’s pool are a metal grid and the reactor’s removable thermal shields. The uranium fuel is long gone. The plan is to use remotely operated, special tools to dismantle the grid and thermal shield and remove those highly activated materials. Otherwise, maintaining the ORR in its current state amounts to a considerable ongoing expense.

Currently, maintaining the pool’s water level is the most significant cost in managing the facility. If further pool characterization indicates removal of those highly activated objects would allow the pool to be drained, the ORR’s hazard rating would drop to that of a radiological site, which would be much less expensive to maintain.

“The long-term plan is to move everything out and demolish the building,” Bratati says.

Preparations to demolish some adjacent supporting facilities, such as a cooling tower, have already begun.—B.C.

ORNL people

ORNL people

Virginia R. Tolbert of the Environmental Sciences Division has been awarded the Distinguished Service Award for 2001 by the North American Benthological Society for her 10 years of service to the society’s finance committee.

Charles Kenneth Bayne, a senior research staff member in the Computer Science and Mathematics Division, has been named a fellow of the American Statistical Association. Bayne was recognized for his work in developing applicable statistical methodologies and for consulting and collaborative work.

A family of nanostructures discovered by the Chemical and Analytical Sciences Division’s Lætitia Delmau, Jeff Bryan and Bruce Moyer and former CASD members Nancy Engle and Rick Sachleben has been featured on the cover of Calixarene Molecules for Separations, a book published by the American Chemical Society.

SEED launches student toward career

SEED launches student toward career

Instead of flipping burgers, a Morgan County student has begun a journey toward a career in science education, thanks to a summer educational program at ORNL.

Patty Summers has finished the program and begun her freshman year at Tennessee Technological University. It was her second year in the Summer Educational Experience for the Economically Disadvantaged Project.

“A lot of things started to change in my life when I was accepted for the SEED Project,” Patty says. “At a time when many of my high school friends were working at fast-food restaurants for summer jobs, I was traveling to ORNL each day to help design a neural network program for determining from a couples’ history if they would be able to have children.”

|

| Patty Summers in the lab at ORNL |

Patty was a rising senior at Wartburg Central High School when she was one of five chosen in 1999 to participate in SEED.

“Before SEED I thought perhaps I could be a teacher and had thought about both high school and elementary. After my second session with SEED, I knew I wanted to be a chemistry teacher at Wartburg Central High. And the initial SEED opportunity opened the door for me to apply for and win a $5,000 scholarship from the American Chemical Society that I am using this fall at Tennessee Technological University at Cookeville.”

Project SEED is a work-study program offering high-school students an opportunity to serve eight- to 10-week appointments at ORNL under the direct supervision of a researcher-mentor.

Patty’s project this summer was “Alternative Hydrogen Production using the Hyperthermophilic Eubacteria Thermatoga Maritima.” She has enrolled at Tennessee Tech in a major in Secondary Education-Chemistry.

“I decided that I would really enjoy teaching students how to work in a chemistry lab. The SEED program has allowed me to see what the ‘real life’ of working really is and it has also helped me in deciding what I really enjoyed doing the most. I would deeply recommend any student to apply to work through Project SEED. It was a great experience.”—Marty Goolsby

FIRST LEGO challenges young minds

FIRST LEGO challenges young minds

Youngsters age nine to 14 are being challenged to sign up for FIRST LEGO League ORNL,Tennessee Technological University and the American Museum of Science and Energy are sponsoring the state tournament set for December 2 in Cookeville.

The competition challenges students to create working, problem-solving robots from the popular building blocks and electronic components.

“It’s a way for inspiring curiousity in science and technology,” says the Robotics and Process Systems Division’s Brad Weil. “It will teach the children teamwork, problem solving and creativity. It’s sports for the mind.”

Brad became an advocate of FIRST LEGO after reading about it on the Internet. ORNL and Tennessee Tech are coordinating the competition in the state with support from the American Museum of Science and Energy.

FIRST (For Inspiration and Recognition of Science and Technology) LEGO teams, which consist of seven to 10 players, are given a problem emulating a real-world event and given eight weeks to create a robot capable of accomplishing the objective of the challenge.

Coordinators expect as many as 30,000 youngsters to participate. Teams can come from schools, clubs or other organizations. In Tennessee, ORNL and TTU are distributing and encouraging FIRST LEGO League registration. Contact Claretta Sullivan (241-3653; sullivancj@ornl.gov) for more information.

November enrollment set

November enrollment set

Benefit Plans will hold its annual open enrollment for the CIGNA and Healthsource point of service plans, the MetLife Dental Plan and Flexible Spending Accounts for employees and retirees in November instead of October, as was announced in the September issue of Reporter.

Employees who wish to change insurance carriers or pick up coverage for themselves or dependents may enroll in November with an effective date of Jan. 1, 2001. Current coverage for all participants will remain in effect unless a change or addition is made to medical or dental plans.

Employees must re-elect Flexible Spending Accounts each year—both the health care and dependent care accounts.

Benefit Plans will send a letter containing the details of the open enrollment to all benefit participants before November 1. Look for the OneCall logo on an envelope in your mail.

Premium holidays extended

Premium holidays extended

Benefit plans has also announced that the premium holiday for the Dental and Group Life Insurance Plans that began in June 2000 will be extended through October and November 2000.

For employees paid weekly, the suspension will continue through the period ending November 26. Group Life deductions are taken on a weekly basis. Dental premiums are deducted the second pay period of each month.

For employees paid monthly, no Dental or Group Life premiums will be taken from the October and November 2000 payrolls. Deductions will resume with the December 2000 payroll. Contact the OneCall Benefits Service Center at 574-1500 if you have questions.

Firefighters urge employees to plan ‘Great Escapes’

Firefighters urge employees to plan ‘Great Escapes’

The ORNL Fire Department has invited ORNL employees to participate in a “great escape” from fire hazards in the workplace as part of Fire Prevention Week this year at the Lab. The week-long event, October 7–14, sponsored by the Fire Department, includes portable fire extinguisher demonstrations, fire safety displays, fire department equipment and apparatus exhibits, and fire safety handouts to employees.

The theme of this year’s national Fire Prevention Week is “Fire Drills: The Great Escape!” The goal is to make people safer from fire by motivating them to develop and practice a home fire escape plan.

David Baity, ORNL Fire Department manager, says, “This is the time of year to rejuvenate our awareness of fire hazards and our focus on fire prevention activities.”

David encourages employees to look around their offices, laboratories, and shops for fire hazards. Some common fire hazards include poor housekeeping, overloaded electrical circuits, improper use of portable heating equipment, improper storage of flammable liquids and improper use of electrical extension cords.

“When hazards are identified, take action to eliminate or minimize the hazard,” David says. “Ensuring the operability of automatic fire alarm systems, fire suppression systems, and fire fighting equipment at ORNL is a responsibility that the ORNL Fire Department takes very seriously. Take some of this responsibility home with you today!”

Some of the measures for the home include testing smoke detectors and changing the batteries at least once a year. Check the gauges on portable fire extinguishers to see if they are pressurized. Give the fire extinguisher a good shake and invert it to loosen the dry chemical agent inside.

|

| Tom Bethea and Captain Peggy Richardson from the ORNL Fire Department instruct Plant and Equipment electricians R. W. Rogers and Larry Bivens on the proper selection and use of portable fire extinguishers. |

“An admirable fire loss record is an obvious indicator of the overall Fire Protection Program’s success,” David says. “Each year brings new challenges that threaten ORNL’s admirable fire loss record. This year the challenge is change. With all the ongoing and planned changes at ORNL, the potential for an unwanted fire increases. Employees and facility users should continue their high level of fire safety awareness.”

Every 18 seconds a fire department responds to a fire in the United States. In 1998 public fire departments responded to 1,755,500 fires that took the lives of 4,035 civilians and injured over 23,000. Home fires accounted for 80 percent of the fire deaths.

“Installing and maintaining smoke detectors, having an awareness of fire hazards, and developing and practicing a home fire escape plan are key elements to surviving a fire in your home,” David says. “Make a home fire escape plan today and practice it at least twice a year.”

The staff of the ORNL Fire Department conducts routine fire safety inspections and evaluations. If you have any questions or need assistance with a particular fire safety issue, call the ORNL Fire Department business telephone number, 574-5678. To report emergencies, dial 911.—B.C.

ORNL office: P.O. Box 2008, Oak Ridge, TN 37831-6146, Building

4500-S, Room F-60, MS 6146

ORNL help line (ethics; fraud, waste and abuse; quality; ES&H)

576-9000

[an error occurred while processing this directive]

[an error occurred while processing this directive]

Bill Cabage, lead editor, ORNL, 574-4399 (cabagewh@ornl.gov)

Deborah Barnes, associate editor, 576-0470 (barnesds@ornl.gov)

Ombudsman: 576-7802

DOE inspector general hotline: 1-800-541-1625