|

Number 71, October 2005 |

Silver linings

Silver linings

The dark cloud of Katrina gives a Xavier University researcher an unexpected opportunity

|

| New Orleans resident Shubha Kale Ireland’s track record as a researcher led to an opportunity at ORNL and a temporary home for her family. |

You wouldn’t know just by talking to her

that Shubha Kale Ireland has just been through a catastrophe. She projects a thoroughly positive outlook. But she and her family experienced, along with thousands of others, one of the nation’s worst calamities: Hurricane Katrina.

“People were talking a little about this storm in the Gulf, and my husband said on Saturday that maybe we could have a bag packed,” recalls the researcher and New Orleans resident. She checked on her experiments anticipating at most a three- or four-day absence.

“Then, early Sunday morning, he woke me up and said, ‘We have to go.’”

What followed were the now familiar evacuation traffic jams, the storm itself and an anguished period of not knowing the whereabouts of her husband, Rick, who stayed behind for several hours to secure the house. The family then spent days of not knowing whether they had a home or a job.

Shubha is a microbiologist and geneticist at New Orleans’ Xavier University. Her husband Rick is a lawyer and a doctoral student in finance. They have a son, Kaitan, 6.

In the haste to leave the area, the Irelands left nearly everything behind. Like many, they had essentially what they could throw in the car.

Their first refuge, Baton Rouge, was mayhem. The city, although relatively undamaged, lost power and cell phones were either out of commission or jammed. It was some time before she knew if Rick was safe.

“I even left my passport and driver’s license behind in the rush,” Shubha says.

The Irelands, as countless others in the region, also left behind much of their lives. For Shubha, experiment samples dependent on refrigeration are undoubtedly destroyed. Many of her papers and research documents were irretrievable and possibly destroyed at the college, as was likely much of her collaborative work at nearby Tulane and for the U.S. Department of Agriculture.

“It’s heartwrenching,” she says of her own and countless other research experiments the storm and the aftermath ruined.

However, she did know where an excellent curriculum vitae was: She had recently been nominated for an award and had sent in information. Earl Hayes of the White House Initiative on Historically Black Colleges and Universities noted her field of research and the strength of her work, which includes many published abstracts, and mentioned her case to Will Minter, director of ORNL’s Asset Management and Small Business Division, who set in motion a process that has given the Irelands an opportunity to resume life in Oak Ridge.

Shubha now has an office in the Life Sciences Division’s Biochemical Engineering Research group in Building 4505 under group leader Jonathan Mielenz. She has a five-month research appointment arranged through the efforts of Will, the Office of Science’s Peter Faletra, University Partnerships Director Lee Riedinger and the Oak Ridge Institute for Science & Education. Chief Finance Officer Greg Turner helped Rick find a part-time position in the Business and Information Systems Directorate.

The Irelands returned home for a short time just after the storm. It was damaged by a fallen pecan tree and other effects of the storm.

“Every tree in the city is blown down or bent over,” Rick says.

The Irelands were luckier than others: Their home sits on a old natural levee and is on high ground, spared from the flood. Conditions in the New Orleans area after the storm, however, were hellish.

“There was no water—it was so dirty you couldn’t wash clothes in it. No stores were open and the schools were closed. You couldn’t get anything repaired. You can’t live that way,” Shubha says.

The Irelands dined on the military’s Meals Ready to Eat—they have vegetarian MREs, she learned—and answered one evening to the unsettling knock of a soldier who had noticed lights on in their house.

|

| Rick, Kaitan and Shubha Ireland at Rick’s parents’ home in Florida, where they briefly stayed after Katrina struck New Orleans. |

The family left New Orleans for Indialantic, Fla., to stay with Rick’s parents, when Shubha was contacted about the opportunity at ORNL.

Will gave Carol Leffew the task of making arrangements for the Irelands. In short order, she lined up the use of a house in the River Run development from local realtors Tom and Peggy Hanrahan and gathered donated household items from Business & Information Services employees and a local rental firm.

“I could tell right away she meant business, that she could get things done,” Shubha says of Carol.

The new family was soon being called on by neighbors bearing cookies and muffins. Kaitan has enrolled at Woodland Elementary School.

“A neighbor boy came over and asked if Kaitan could play,” Shubha says. “He likes it here.”

The Irelands plan to go back to the New Orleans area in January to possibly pick up life as they knew it.

“You don’t desert a university when it’s down,” she says, also noting the uncertainty of whether Xavier and the New Orleans community will ever fully recover. In the meantime, Shubha hasn’t wasted any time in resuming her research career.

“Since this is a new project for me, there are new techniques to learn and new equipment to use. It is like being a graduate student all over again. However, each and everyone in the group—Dr. Mielenz, Abhijeet Borole, Choo Hamilton, Babu Raman, Miguel Rodriguez, Cathy McKeown and Ann Luffman—have been so very helpful in showing me the ropes that the transition has been smooth. Indeed, I feel fortunate to be a part of this team and the ORNL family,” Shubha says.

“We are very thankful for all of the help we’ve received and this wonderful oppor-tunity. I can do some good science here.”—B.C.

Hard winter ahead: ORNL seeks ways to trim energy costs

Hard winter ahead: ORNL seeks ways to trim energy costs

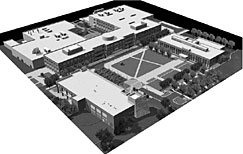

|

| The new campus has some of the Lab’s least energy-hungry buildings. |

It’s an annual preoccupation but this time

around may be worse than usual. ORNL will be joining the nation this winter in getting the shivers over the utility bill.

Supply disruptions caused by the Gulf hurricanes and increasing demand have experts forecasting steep price increases for natural gas in particular. ORNL’s steam plant converted from coal to natural gas several years ago, and this winter could prove expensive if it’s a rough one.

“We have to give our gas supplier an estimate on how much natural gas we’ll use so that they can plan. If we go over that estimate, we pay at a premium,” explains Greg Palko, ORNL’s energy efficiency manager in the Facilities Management Division.

ORNL’s utlility bill last year for both procurement and operating and maintenance was about $31 million. About 60 percent was procurement, or buying electricity and natural gas. The steam plant’s system is backed up by heating oil. Coal, though cheap and abundant, is no longer a fuel option mainly because of pollution restrictions.

“We bought $7 million worth of natural gas last year, so if prices rise by at least 50 percent as some have speculated, our bill will go up $3.5 million.”

| Individual efforts can keep the utlility bills down. Multiply each effort by the 4,000 staff members on site and savings add up. |

On the up side, the Lab’s modernization campaign will soften the impact. All three facilities on the new east campus—the Conference Center, the Research Office Building complex and the Joint Institute for Computational Sciences—are Leadership in Energy and Environmental Design, or LEED, certified, meaning they are among the most energy efficient in the nation.

“We’ve done a great job with the new buildings. The awareness month poster that DOE is using throughout the DOE system features our new buildings,” Greg says.

On the down side, some of the Lab’s older buildings are energy hogs. The heavily populated 4500 complex has a particularly healthy appetite.

“Building 4500-South alone uses just over 10 percent of the Lab’s heating and cooling energy,” Greg says.

It’s not that South’s residents are wasteful. Greg explains that the building has many research labs and thus many ventilation hoods, which means that the building’s air is once-through and not recirculated, as in the newer buildings.

“But we can improve the building’s efficiency by upgrading the supply fan and exhaust hood systems so that unused hoods don’t pull as much air,” Greg says.

Greg says that FMD is also aggressively fine-tuning and upgrading the Lab’s steam system.

“This includes fixing steam traps, repairing leaks, removing condensate from the system and applying insulation to bare lines,” he says.

One such insulating project is visible from White Oak Avenue, where a 700-foot section of steam line bound for the 7000 area has received a new cladding of insulation.

“The payback on that improvement is less than a year,” Greg says.

The individual staff member can do his or her bit to keep the bills down. Multiply each effort by the 4,000 or more staff members on site, and the savings add up.

“Improving and updating your office equipment can save electricity,” Greg says. “Old CRT monitors use a lot of energy; the newer flat screens use much less. These old monitors may still work great, but they are electricity hogs. You may be saving money by not upgrading, but on the whole, it’s probably costing the Lab more.”

Conserving is often just common sense. If you must use a space heater, be sure to unplug it at night and over the weekends or put it on a timer so that it doesn’t run.

Even better, if your office is too hot or cold, report it. FMD, according to Greg, is redoubling its efforts to adjust the temperature zones in the offices so that employees won’t have to resort so often to heaters and fans, which represent a “double whammy” on the energy bill.

Newfangled appliances have neat energy-saving features. Electric strips are available that now have motion sensors on some of the outlets. “Some things that need to run continuously, such as your CPU, can run all the time, but your printer, another energy hog, will shut off when you aren’t there,” Greg says.

For more advice on saving energy, contact Greg, 574-4088.—B.C.

State’s joint institute declared ‘green’

State’s joint institute declared ‘green’

The U.S. Green Building Council has

recognized the efforts and accomplishments of the state of Tennessee and ORNL teams by awarding Leadership in Energy and Environmental Design Green Building Certification, or LEED-NC Silver, to the Joint Institute for Computational Sciences and Oak Ridge Center for Advanced Studies.

LEED certification identifies JICS-ORCAS as a pioneering example of sustainable design and demonstrates our leadership in transforming the building industry and marketplace. The JICS-ORCAS facility has earned this recognition for excellence in the built environment and a place among the finest measured green buildings. ORNL’s Facilities Development Division, Computing and Computational Sciences, and Facilities Management Division were instrumental in the planning and execution of the project, and the additional partnership of the state of Tennessee has made this accomplishment possible.

“Sustainability has been a major element of the ORNL modernization since its beginnings five years ago. The Silver certification of the JICS facility is the most significant achievement of this initiative to date,” says Lanny Bates, director of ORNL’s Facilities Development Division. “We are proud to be a part of the leadership for sustainable buildings. It’s not only the right thing to do but it also provides a pleasant working environment that our staff can enjoy and be proud of.”

The facility will use at least 25 percent less energy than a conventionally constructed facility. Elements that save energy include highly insulated reflective roofs, low-energy windows, additional wall insulation, higher-efficiency lighting including natural daylight through windows and atrium clerestory, high-efficiency air-conditioning systems and Energy Star office equipment. Special air filters and carbon dioxide monitors ensure healthy indoor air quality, and adjacent landscaping of native plants minimizes the building’s heat-trapping sun exposure. Annual energy cost savings attributed to these modernizations is approximately $500,000.![]()

Governor touts Lab-state potential

Governor touts Lab-state potential

Gov. Phil Bredesen visited ORNL on September 15, his first trip to the Lab as governor. Sights he saw included the Spallation Neutron Source, the Center for Computational Sciences and the state-funded Joint Institute for Computational Sciences.

“I have to bring my son,” he said. He also jestingly hinted that he wouldn’t mind having a set of keys to the state-funded joint institute.

Bredesen says the Lab’s growing science programs can be an economic boon for the state.

“Any time you bring together these capabilities, you attract capital investment. There are examples where intellectual capital has driven economic development, and we can do it if we’re smart and play our cards right,” he says.

|

|---|

Jeff Wadsworth, Gov. Phil Bredesen, SNS Director Thom Mason and UT President John Petersen reflect on the Spallation Neutron Source. |

Tennesseans should “get on focus, invest, make it ours and feel ownership” in the Lab and its intellectual capital. He said the SNS, which he has been talking about since becoming governor but actually saw for the first time that day, “puts us right on the cutting edge—a huge advantage for Tennessee, and right in our own backyard.”

The governor also praised the response and charity in the aftermath of Hurricane Katrina. Lab Director Jeff Wadsworth, Deputy Gov. Dave Cooley and University of Tennessee President John Petersen accompanied the governor.

New curves on Bethel Valley Road

New curves on Bethel Valley Road

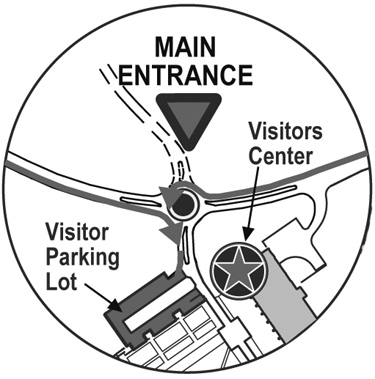

Bethel Valley Road’s roundabout is now open. Drivers are now getting accustomed to the traffic-calming device at the main Visitor Center entrance.

Navigating the roundabout isn’t difficult. For through traffic, drivers mainly just need to slow down to negotiate the semi-curve. Large vehicles such as semi trucks have a wide apron on the inner section of the circle to compensate for the tight turn radius.

|

If you are new to traffic circles, getting into the visitor parking lot from the east will be different. To reach the Visitor Center lot, which would be a left turn in a typical intersection, drivers should bear instead to the right and go three-quarters of the way around the circle until they reach the parking lot entrance. Westbound traffic yields for these oncoming drivers.

A new parking lot on the north side of Bethel Valley Road, when it opens later this fall, will be similarly accessed by westbound traffic—by bearing right until the driver reaches the parking lot.

There are no left turns in a roundabout.

Visitors, who will most commonly enter the Visitor Center lot, are being advised of the feature at the vehicle entrances.

With Bethel Valley Road traffic being one of the Lab staff’s primary safety concerns, the roundabout, besides becoming a prominent landmark on the ORNL campus, promises to slow folks down.

Nanoscience center opens

Nanoscience center opens

The first day of Fiscal Year 2006, October 1, was also the first day of business for the Center for Nanophase Materials Sciences. The CNMS is the first of the Office of Science’s nano centers to be completed, this one located strategically adjacent to the Spallation Neutron Source, which is homing in on its own completion early next year.

“With the new fiscal year, we have operating funds now,” a gleeful CNMS Director Linda Horton says. “We’re ordering phones, chemicals for the labs and the host of other operating items needed for full operations of the facility.”

Previously, funds were for facility construction activities.

While the paint dries and the first research proposals for the new FY enter the final stage of the review and approval process, the nanoscience center’s bank of computers—the theory cluster—is up and running.

The theory cluster is part of a new “ORNL cluster” of parallel computers that will provide computing resources to Lab researchers as much of the terascale supercomputing time in the Center for Computational Sciences becomes dedicated to larger projects of the National Leadership Class Computing Facility.

The Computer Science and Mathematics Division’s Jack Wells says the theory cluster gives nanoscience center researchers and users the computing resources that have become so central to their work.

“The cluster will be the workhorse for the theoretical simulations developed in the nanoscience center’s Nanomaterials Theory Institute,” Jack says. The NTI is led by Peter Cummings, a visiting distinguished professor from Vanderbilt and longtime ORNL

collaborator.

Jack says a hallmark of the theory cluster is the close working relationship the nanoscience center is building with the CCS. He believes ORNL’s early recognition of the role of computational science gave the Lab a leg up in the nanoscience race.

“ORNL’s nanoscience center proposal was one of the first to stress theory, modeling and simulation to a large degree, and the investments we are making in midrange computing will keep us out in front,” Jack says.

—Reported by Bill Cabage |

|

|---|

Vine Magnet School’s West African dancers highlighted September 27’s International Festival, which raised nearly $5,000 for the United Way. |

From here to eternity

From here to eternity

ORNL team leads tricky thorium nitrate disposal project, saves taxpayers millions

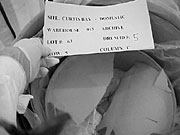

|

|---|

|

Jim Terry (left) and Bill Hermes pay their respects at the Nevada Test Site, the final resting place of 21,000 barrels of surplus thorium nitrate, shown in the background. |

It probably seemed like a good idea at the

time. Beginning in 1957 the Atomic Energy Commission, DOE’s forerunner in nuclear matters, commissioned contracts for processing tons of monazite sands into thorium nitrate hydrate for the potential production of nuclear reactor fuel.

Thorium nitrate contains thorium-232, a naturally occurring radioisotope that can be transformed in a nuclear reactor to uranium-233. As matters turned out, the thorium fuel cycle market never materialized and the government wound up with 7 million pounds of excess thorium nitrate. For the past several decades, the stockpile has been stored near a couple of large urban areas—Hammond, Ind., near Chicago, and Curtis Bay, Md., near Baltimore.

The Defense Logistics Agency’s Defense National Stockpile Center inherited the trove and began looking for a solution to what to do with the material. The DNSC in 1994 commissioned an East Tennessee Technology Park team, led by Bill Hermes, to assess processing technologies for converting the thorium nitrate from a mixed waste into a low-level waste. That trail was picked up again in 1999 by ORNL, which has long held expertise in characterizing and handling nuclear material. The Work-for-Others Thorium Nitrate Stewardship and Disposition Project was approved and again landed in the hands of Bill, now in the Nuclear S&T Division.

Bill had the previous direct experience with the thorium stockpile and at ETTP was the principal engineer for the TSCA Incinerator from conceptual design through licensing.

“National defense and industry people come to ORNL because of our expertise in nuclear waste and safety,” Bill says. “Our initial task was to characterize the thorium nitrate and decide how it could be safely transported and disposed of. Just as important were decisions on how the material was to be classified and managed in a regulatory sense. Those decisions could mean the difference in tens of millions of taxpayer dollars, as well as minimizing dose to the radiological workers involved.”

Something needed to be done with the inventory because of its location near heavily populated areas.

“The material is a gamma-dose hazard,” Bill explains. “The government went through two or three repackaging campaigns from the 1960s through the 1980s. With no nuclear or other market in place, the stockpile was a liability and the managers were looking for a disposition option.”

Bill enlisted the services of a multidisciplinary ORNL team, including the Environmental Sciences Division’s Jim Terry as a principal co-investigator to manage the National Environmental Policy Act issues. Those NEPA issues weighed heavy in deciding what to do with tons and tons of what was yet to be decided as being a waste material or something else.

ORNL recommended to the DNSC disposal of the material at either a commercial or federal site. That initiated, in Bill’s words, a “rigorous characterization phase.”

“We sampled each lot within the stockpile, constituting more than 100 drums of the thorium nitrate, and took hundreds of digital photos to document the material and drum condition,” Bill says. “We determined that it was not an oxidizer and, therefore, not a mixed waste.”

The ORNL team convinced regulators that the material could be shipped “as is,” and did not require processing. Winning that argument saved the taxpayers the cost of designing, constructing and operating a processing plant that would have cost $40 to $50 million. Also, the historical records documenting the AEC tie was sufficient basis for DOE to accept transfer of the source material from the Defense Department.

“This action was a huge win for the public and showed the agencies were able to work effectively together,” Bill says.

Determining the condition of the barrels of thorium nitrate presented a challenge. The warehouses they were stored in were packed tight with pallets that contained four to five drums each, and stacked five to six tiers high. A couple of pounds of calcium hydroxide were added to a certain drum type as part of a repackaging campaign completed in the 1980s to neutralize acid seepage. The carbonate impurity in the hydroxide led to carbon dioxide formation.

The off-gases had pressurized some barrels, turning them into potential bombs. Based on research led by Paul Singley at the National Transportation Research Center, a simple test was devised that consisted of laying a steel bar across the top of the barrel. If the barrel head pooched out enough to touch the bar, it was deemed to be under pressure, like a can of beans gone bad.

As it turned out, relatively few of the 21,000 drums had to be vented. The test saved the expense of puncturing and HEPA filtering for each drum and, more importantly, avoided significant dose to the contracted radiological workers.

Another complication was the thorium nitrate inventory itself. It wasn’t all the same. Most was mined and produced in the United States from monazite sand. Small but significant portions of the stockpile, however, were produced in France with ore from Madagascar, and in India using Indian ore. The French material was higher in thorium-230 because the uranium-238 in the ore was significantly higher. The team had to be careful to assure that shipments did not exceed radiological DOT limits for transport. A model recommended mixing shipments with domestic and offshore drums, and it proved to be on track.

| Convincing regulators that the material did not require processing saved up to $50 million. |

ORNL specified that new 20-foot cargo containers be used as both the disposal and shipment package, which avoided assessing the quality of the drums and minimized radiation dose by allowing for handling cargo containers at the disposal site versus individual drums. The sponsor supported the decisions and paid DOE around $7 to dispose of each cubic foot of thorium nitrate. The ORNL team in 2003 estimated that the job would require 266 containers. That prediction was also on the money.

Maintaining quality and certification records for operations entailed a highly rigorous regime of requirement tracking, electronic filing, paperwork and communications. Bill said that the shipping procedure alone, assembled principally by Mark Hawk at the NTRC, was 50 pages. NRC source material accountability requirements had to be met, as well as constant validation of program certification and shipment requirements. More than 25,000 records were generated.

Safety was an imperative, “pounded on” in

daily planning meetings. The thorium nitrate, while not a fissile material, represented a gamma dose requiring careful packaging and handling. Much of the loading work had to be done outside in cold and rainy conditions. There was thorium-232 contamination on the exterior surfaces of the foreign drums, pallets and floor area, as well as 400,000 pounds of pallets and floor covering to pick up and dispose of. The lead operations contractor, RWE Nukem of Columbia, S.C., and their subcontractors worked more than

32,000 hours with no reportable injury.

On August 30 the last of 266 truckloads of containers of thorium nitrate arrived at the Nevada Test Site. In all, the ORNL team “retired” more than 21,000 barrels in a series of shipments to NTS that began, finally, in September 2004.

The material is buried in dedicated trenches in the desert. The drummed inventory is well documented and located hundreds of feet from any water. The stockpile could be retrieved if the economics ever support it. There is no hurry, since the thorium-232 has a 14- billion-year half-life.

There were no lost-time accidents during the course of the overall project. The eventual cost of the project was just over $17 million when, except for the ORNL knowledge and technical sleuthing, it could have been up to $70 million.

Michael Pecullan, the Defense National Stockpile Center’s thorium nitrate project manager, says the process was very intense leading up to actual transfer of the material.

|

| Determining the condition of the barrels of thorium nitrate was a challenge for the ORNL-led disposal team. In the end, relatively few of the barrels had to be opened. |

“This was the most complex project undertaken by DNSC in my 28 years with the organization,” he says. “It could not have been completed without the many cooperative efforts, and especially the superb project oversight provided by a team of professionals from UT-Battelle who worked at ORNL on behalf of DNSC.”

Bruno Zovi of the Nevada Test Site’s Radioactive Waste Acceptance Program calls the ORNL team’s job on the shipments “exceptional” in its lack of any issues.

The final phase of the project will be to assist the Defense Logistics Agency in closing out the Hammond and Curtis Bay depots. This scope is no small task, since the material was stored in deteriorating conditions and handled many times over the years.

For Bill and Jim and the rest of the ThN team, the thorium nitrate retirement project’s culmination brings a sense of satisfaction.

“There were technical research problems to solve, as well as programmatic and health and safety barriers to overcome,” says Bill. “We did it through a dedicated and disciplined team, and we solved a problem of national importance.”—B.C. ![]()

New badging requirements for employees begin

New badging requirements for employees begin

ORNL staff members will soon be dealing with a new badging process that has been mandated across the federal government by President Bush. The order comes through an initiative sponsored by the Department of Homeland Security and the National Institutes of Standards and Technology.

Homeland Security Presidential Directive 12 is an effort to create a common identification standard for federal agencies and includes a security initiative called Personal Identity Verification. Under the plan, the new badge will be accepted as identification at all federal agencies.

The first phase, which must be in effect by October 27, is primarily aimed at new employees, who will undergo fingerprinting and a five-year background check. Guests and visitors will also come under the directive, but many details have yet to be determined.

For current staff members, a transition plan is being developed and more information will be available in the coming year. What is currently known is that the second phase will include issuance of a “smart card” to employees that will contain fingerprint information and other identification for access to facilities and computer systems.

Badge types will be temporary, short-term and long-term. Badge applicants will be required to produce two forms of identification (which can include passport, state driver’s license, birth certificate, military card or a current DOE badge). Upon completion of the background check, a long-term access (greater than six months) badge will be issued.

If the background check takes longer than five days to complete, the applicant will be issued a short-term badge (less than six months) that will be readily distinguishable from a long-term badge.

Issues between agencies are complex, and many features and factors in the rebadging have yet to be decided. The background checks on current staff, called National Agency Check Inquiries, could commence this month. Employees will be notified of the NACI checks.

Staff members who have Q or L clearances likely will have already completed requirements for the new badges. ORNL Security and Computer & Network Security will strive to minimize the impact of the initiative on ORNL research and employees.

Staff can forward questions to the HSPD-12 mailbox at hspd12@ornl.gov and obtain HSPD-12 information at the HSPD-12 Website at home.ornl.gov/ornlhome/hspd-12.shtml.![]()

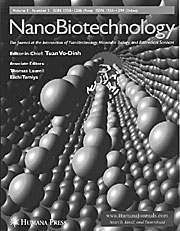

Vo-Dinh sees new journal advancing nano-bio field

Vo-Dinh sees new journal advancing nano-bio field

|

|---|

Tol. 1, No. 1 of the journal NanoBiotechnology, which Editor-In-Chief Tuan Vo-Dinh believes will provide a valuable forum for a growing interdisciplinary field of research. h |

Editor-in-Chief Tuan Vo-Dinh envisions the new international peer-reviewed journal NanoBiotechnology providing a forum that leads to “explosive growth” where nanotechnology and biomedical sciences converge.

“Current and future research achievements in nanobiotechnology could ultimately lead to the development of revolutionary modalities of biomolecular manufacturing, early diagnostics, medical treatment and disease prevention beyond the cellular level to that of individual proteins,” says the corporate fellow and leader of the Life Sciences Division’s Advanced Biomedical Science and Technology group.

The first edition of NanoBiotechnology, which has a 46-member editorial board, was issued this summer and features 10 papers. Topics include visualizing nature at work from the nano to macro scale, potential nanotechnology treatments for localized articular cartilage defects and an optical nanotool to study protein organization at the cell membrane.

In the journal’s introduction, Tuan, Thomas Laurell, associate editor for Europe, and Eiichi Tamiya, associate editor for Asia and Pacific Region, write: “The journal is intended to serve as an authoritative forum that timely presents the state-of-the-art multidisciplinary research and technological advances in theory, instrumentation and methods, as well as applications in various areas of nanotechnology related to biology and medicine.”

Potential topics include molecular bioprobes, nanoparticles and nanobiosystems, nanobiomaterials, biomolecular assemblies and supra-biomolecules, nanobiosensors and nanobiochips, BioNEMS and nano-biofluidics, nanobiophotonics, single-molecule detection and manipulation and molecular motors.

“This journal will provide an excellent forum for publishing interdisciplinary research in the very exciting and rapidly growing area of nanobiotechnology,” says Rashid Bashir, an editorial board member and professor in Purdue University’s Department of Biomedical Engineering. “The journal is very timely and the topics that will be covered encompass all the key areas of research in nanotechnology as they are applied to biology and medicine.”

More than 40 international academic institutions are represented on the editorial board, including the University of Basel, Switzerland; Nagoya University, Japan; Columbia University, Cornell University, Harvard University, Princeton University, Stanford University, Ohio State University and the University of Michigan; the University of Crete, Greece; Johns Hopkins School of Medicine, University of California at Berkeley, Los Angeles and Santa Barbara; University of Paris; University of Tokyo; Kyoto University, Japan; and University of Technology, Melbourne, Australia.

The journal, published by Humana Press, employs a paperless article submission and peer review process. Submissions should be sent to submit.humanajournals.com—Ron Walli ![]()

ORNL people

ORNL people

|

| Wadsworth |

Laboratory Director Jeff Wadsworth was inducted October 9 into the National Academy of Engineering at a ceremony in Washington, D.C. Jeff is one of 17 NAE members currently or formerly associated with Oak Ridge. He is the third ORNL director named to the academy, joining Alvin Weinberg, who was elected in 1975, and Al Trivelpiece, elected in 1993. Jeff was named to the NAE for his research on high-temperature materials, superplasticity and ancient steels and for leadership in national defense and science programs.

Scott Studham has been named ORNL chief information officer, responsible for planning and executing a coordinated information technology strategy. The CIO function will remain in the Computing and Computational Sciences Directorate but will report to the Laboratory Director’s Office in matters relating to policy.

Scott replaces Becky Verastegui who for the past seven years has served as both CIO and director of the Networking and Computing Technologies Division, which she will continue. Scott’s experience includes recent appointments as chief technology officer for the Center for Computational Sciences at ORNL, associate director for Advanced Computing at Pacific Northwest National Laboratory and information technology project manager for IBM at the National Weather Service.

ORNL retiree Richard Gwaltney has received the American Society for Mechanical Engineers’ Pressure Vessel and Piping Medal. Richard worked in the former Engineering Technology Division until he retired in 1996.

The former Operational Safety Services Division is now two divisions, the Nuclear and Radiological Protection Division and the Safety Services Division. NRPD will be directed by Michael Stafford, who was recently group leader for Nuclear and Radiological Support Services and leader of the facility characterization upgrade program. Michael L. Baker will direct the Safety Services Division, effective Nov. 1. Mike comes from Y-12’s Technology Development organization. Carol Scott, who has directed OSSD for the past five years, will serve as operations manager for the ESH&Q Directorate.

The Computer Science and Mathematics Division’s Nageswara S. Rao won a best paper award for his paper titled “Identification of Class of Simple Product-Form Plumes Using Sensor Networks.” The paper will be presented at the Innovations and Applications of Distributed Sensor Networks Symposium this month in Washington, D.C.

Will Minter, division director for Asset Management and Small Business Programs, has been appointed to the board of advisors for the College of Business at the Tennessee State University in Nashville.

Technology Transfer and Economic Development Director Alex Fischer has been asked by Battelle's Bill Madia and Lab Director Jeff Wadsworth to lead a Battelle-wide initiative to more fully integrate Battelle's technology commercialization efforts. Alex will continue to manage TTED in this dual capacity.

ORNL welcomes 5 Wigner Fellows

ORNL welcomes 5 Wigner Fellows

|

|

|---|---|

| Baker | Bennink |

|

|

| Daniel | Madden |

|

|

| Melko | |

Lab Director Jeff Wadsworth welcomed the new Wigners and recognized current and former Wigner fellows at the annual reception on September 20. He noted that over the 30 years of the fellowship program, which was begun by the late former Lab Director Herman Postma, about two-thirds of Wigner fellows have remained at ORNL.

Gary A. Baker recently joined the Surface Chemistry & Catalysis Group of the Chemical Sciences Division after postdoctoral work at Los Alamos National Laboratory. Gary received his Ph.D. in 2001 from University of Buffalo, The State University of New York. He has received a number of awards for his research including an ACS Division of Analytical Chemistry Graduate Fellowship and a Frederick Reines Distinguished Postdoctoral Fellowship. He has over 40 peer-reviewed publications and three patents. Gary’s cross-disciplinary background in physical, materials, and bioanalytical chemistry provides a strong platform for his current research into the application of ionic liquids.

Ryan Bennink received his Ph.D in 2004 in optics from the University of Rochester, New York. As a student, Ryan was the recipient of several awards, including the Sproull Fellowship, the Nelkon Prize, and the Granville Prize. He has also produced 14 publications including seven as first author, in notable journals. At ORNL, Ryan is working with Warren Grice in the Computer Science and Mathematics Division. Ryan’s past work has explored the momentum entanglement of classical and nonclassical light sources. His forthcoming work will continue future development of quantum optics phenomena in quantum information science.

Claus Daniel received his Ph.D. this year in thin films and mechanical properties from the University of Saarland, Germany. Claus joined the Metals & Ceramics Division, Surface Processing & Mechanics group, at the High Temperature Materials Laboratory, where he is under the direction of Ted Besmann. He is pursuing his interests in laser surface modification of materials for mechanical and functional applications. Claus has produced five publications, all as first author, in notable publications. He also is the recipient of the prestigious Carl-Eduard-Schulte-Prize from the German Engineering Society and the Young Professionals Award from the German Materials Research Society.

Megan Madden joins the Environmental Sciences Division following the receipt this year of her Ph.D. in geosciences from Virginia Tech. Among her many achievements, she received research grants from the Barringer Family Fund for Impact Research and the Geological Society of America, and an NSF ADVANCE Ph.D. Fellowship. She has three publications, all as first author. Megan is working in the Gas Hydrate group, under the direction of Tommy Phelps, where she is pursuing her interests in the thermodynamics and kinectics of natural materials and processes.

Roger Melko completed his Ph.D. in physics this year at the University of California, Santa Barbara. In addition to several scholastic awards as both an undergraduate and graduate student, he has 11 publications, including four Physical Review Letters and seven as first author, in notable journals. Roger joins the Theory group, Condensed Matter Sciences Division, under the direction of David Singh, where he will pursue his expertise in computational studies of strongly correlated many-body systems, with applications in electronic properties, low-temperature atomic systems, and magnetic materials.—B.C.

Stallions dies; led Lab security

Stallions dies; led Lab security

Donald Ray Stallions Sr., retired director of the Laboratory Protection Division, died August 31 in Maryville after a battle with kidney cancer. Don’s family came to Oak Ridge in 1944, when he was four. He began at ORNL as a researcher in the former Biology Division. He later transferred to the Laboratory Protection Division, which he eventually directed. Don retired last year after 37 years of service.

New Staff Members

New Staff Members

Brian Keith Goins and Mary Knox Strege, Craft Resources

Ashley Cheryl Clotfelter, Business and Information Services

Wanda Fay Wyrick, Contracts

Virginia Sue Fowler, Robin Eugene Hancock, Andrew Franklin Hobbs and Elizabeth Abernathy Mitchell, Quality Services

Mark Loguillo and Paul Randall Summers, SNS Experimental Facilities

Scott S. Dolvin, National Security

Lora Robin Johnson, Larry Alan Longcoy and Fred Randolph Williams, SNS Accelerator Systems

Patricia Gilbreath Smith, Business & Information Services

Melissa Skidmore Ward, SNS Project and Site Support

Karen Morgan Andrews, Nuclear S&T

Nathan Alan Crowe, Research Reactors

Glen Allen Jennings, Human Resources

Daniel Leon Maierhafer, Condensed Matter Sciences

Christie Dawn Rice, Accounting

David Lawrence West, Engineering S&T

Lab Katrina Relief

reaches $168,000

Lab Katrina Relief

reaches $168,000

For the second time in one year, ORNL

staff members’ charitable response to disaster has topped six figures.

“The selfless charity of the ORNL commu-nity continues to be a point of pride,” says Lab Director Jeff Wadsworth.

The Laboratory’s total contribution to the Katrina Relief effort reached nearly $168,000 by the time the relief account was officially closed on September 29. Employees’ contributions to the ORNL Federal Credit Union account reached $117,647. UT-Battelle is making a corporate contribution of $50,000 to the hurricane relief effort.

Employee funds will go to the American Red Cross. A group from Team UT-Battelle will provide a recommendation about how best to use the UT-Battelle matching funds.

Tsunami relief from ORNL employees and UT-Battelle reached nearly $200,000 earlier in the year, and Lab employees have also reached out to several employees who have suffered more personal misfortunes.

![]()

Bill Cabage, editor, ORNL, 865/574-4399 (cabagewh@ornl.gov)

Deborah Barnes, associate editor, 865/576-0470 (barnesds@ornl.gov)

ORNL office: P.O. Box 2008, Oak Ridge, TN 37831-6146, Building 4500-S, Room F-60, MS 6146

News Deadlines

DOE inspector general hotline: 1-800-541-1625

[an error occurred while processing this directive] [an error occurred while processing this directive]