|

Number 79, July 2006 |

Nanoscience Center users will find ‘one-stop shop’

Nanoscience Center users will find ‘one-stop shop’

|

|

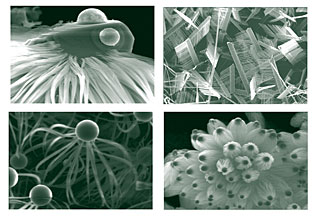

| For the user meeting, the Chemical Sciences Division’s Shengwei Pan made posters of these four scanning electron microscope images of catalyzed materials growth. Clockwise from upper left: A gallium ball, silicon crystal and silicon oxide nanowire; zinc oxide “combs;” gallium catalyzed silicon oxide nanowires; and a gallium and silicon-based “octopus.” |

ORNL’s Center for Nanophase Materials Sciences presented itself as a one-stop shop for nanoscale research during its 2006 Users Meeting June 14-16. The June conference, chaired by CNMS Scientific Director Doug Lowndes, was attended by more than 200 delegates representing both American and foreign universities and laboratories.

The scientists convened at Oak Ridge’s Pollard Technology Conference Center for poster sessions, lectures and briefings on seven related scientific themes through which the nanoscience center’s researchers will address nanoscience challenges and nanotechnology opportunities during the coming year. These themes are macromolecular complex systems, functional nanomaterials, catalysis and nano-building blocks, magnetism and quantum transport, nanofabrication, theory-modeling-simulation, and instrumentation for nanoscale imaging and properties measurements.

Leaders of each theme gave potential users a general idea of the grand challenges to scientific understanding that the nation’s nanoscience research community faces.

The first grand challenge the nanoscience center hopes to overcome is “designing and controlling the nanoscale organization of macromolecular materials,” Phil Britt says about Macromolecular Complex Systems. Focusing mainly on polymers, the group’s co-leader suggested that the new laboratory was a “one stop shop” for users’ polymer needs, including design, synthesis and characterization. Phil, alongside ORNL and UT-ORNL Distinguished Scientist Jimmy Mays, will lead the Macromolecular group as they prepare to use the latest equipment and resources, such as ORNL’s new Spallation Neutron Source, to uncover fundamental properties of polymers and the control scientists might achieve in their synthesis.

Functional Nanomaterials faces four grand challenges. Dave Geohegan says that this group will first focus on controlling the creation of high quality nanorods, nanowires and quantum dots made from a wide range of materials. To design methods for combining the nanomaterials to make new materials, the group members will need to understand the nanoscale mechanics and the materials’ interactions at the nanoscale interface level.

Hans Christen discussed the next two challenges, including collaboration with users to discover new oxide-film materials and synthesis of artificially layered oxide structures, with which the scientists can manipulate magnetic and electric properties of complex oxide materials.

“This is the Lego version of putting down one thing at a time,” Hans says. “It is perfect for nanoscale structure.”

|

The Lego version of putting down one thing at a time is perfect for nanoscale structure. |

The other challenge, Hans says, is to understand how these nanomaterials grow and then to figure out how to control that development. The CNMS facilities allow users unique access to equipment that can monitor the early stages of growth while the nanomaterials are forming, a new approach to analyze and understand their synthesis. The equipment will help ORNL scientists and guest users to uncover how they can control nanomaterial growth and function.

Steve Overbury discussed Catalysis and Nano-Building Blocks, which is a new CNMS scientific theme. Steve says that the researchers will address the task of creating and characterizing catalysts on the level of nanoparticles and nanocrystals. Because the nanoscience center has the ability to use ORNL’s cutting-edge resources—such as the aberration-corrected atomic-resolution electron microscope and other new scanning probe microscopes—and because researchers can collaborate with Functional Nanomaterials group members and users to understand how nanomaterials are composed, major advances are anticipated in this field. Steve says the group will aim to influence energy resource R&D with applications of its studies in hydrogen storage and production, fuel cells, pollution control and other areas.

The challenge within the Nanoscale Magnetism and Transport theme lies in uncovering the origins of magnetism in nanomaterials, as well as learning how to measure the quantum transport of charge and spin through and along ultra-thin film, nanowire and nanostrip surfaces. Jian Shen, working aside UT-ORNL Distinguished Scientist Ward Plummer, will oversee the magnetism and transport scientists as they access a suite of scanning probes and instruments designed to make the nanoscale measurements needed to understand how to grow nanostructures in an ultra-clean environment.

“The scanning electron microscope is dynamic to understanding the magnetism of nanostructures,” Jian says. Understanding magnetic properties and interactions of nanodots will be a key for developing higher data storage on smaller and smaller devices.

Mike Simpson says that his Nanofabrication theme’s scientific focus lies in developing new ways to control nanomaterials assembly, especially for “nano-bio” materials. In collaboration with the Catalysis and Nano-Building Blocks group, Simpson and his colleagues intend to uncover how nanoscale properties and interactions link to materials’ micro and macro structure. Nanofabrication scientists want to go beyond nanostructure, though, and build complete systems, Mike says. The greatest obstacle for this group will be integrating synthesis methods that do not damage any biological material they may be trying to develop.

“We are studying complex systems of organisms and how they are put together,” Mike says. “We want to make a structure that looks like the biological, that mimics cells for example, and then we can change the transport properties or change how we bring things to the cell.”

The Theory, Modeling and Simulation theme is carried out through the CNMS’ Nanomaterials Theory Institute (NTI), which its leader, Peter Cummings, says is available to experimental users for support in the theoretical and computational components of their research.

Peter says the NTI vision is one of integration with the experimental side of the center, providing a problem-solving base for the researchers. The theory institute will aid all the other themes in addressing their challenges, but also will address fundamental challenges of computational nanoscience, most importantly new methods for the functional design and virtual synthesis of nanomaterials.

The theory institute aims to become a world-leading center for nanoscience collaboration, and it already brings together world leaders and users of computational nanoscience, by sponsoring an international program of Computational Nanoscience Focused User Laboratories, or NanoFocULs. The theory institute aims to provide experimental scientists “hands on” access to develop and apply the newest techniques needed to address the nanoscience center’s seven related scientific themes.

“We want to simplify materials,” Peter says. “Anything that works on a nanoscale connects to how it works on the macroscale.” The CNMS themes challenge both theoretical and experimental scientists in identifying that connection. Peter says answering the themes’ questions will rely entirely on collaboration.—Ashley Yeager ![]()

Central campus cleanup

Central campus cleanup

ORNL has a long-range plan for its aged midsection

|

Rusty, musty and dusty old facilities on the central campus are slated for cleanup. |

With its recent growth and new construction, ORNL resembles in several ways a booming city—gleaming buildings, busy sidewalks, lots of visitors, tight parking and new faces.

ORNL also has its rough part of town, known as the central campus. The Environmental Protection & Waste Services Division’s Dirk Van Hoesen refers to the central campus area between First and Fifth Streets, and Bethel Valley Road and White Oak Creek as “downtown.” It’s the part of ORNL, built mostly during the Cold War, that has seen better days.

Dirk currently has the UT-Battelle lead in an ambitious project—part of the ongoing campus modernization campaign—to clean up and tear down the outmoded, disused and often contaminated central campus structures, to reduce risk and prepare the heart of the ORNL site for future uses like the recently announced Oak Ridge Science and Technology Park, future DOE missions and, of course, parking lots.

It’s ironic that the project is named the Central Campus Closure Project, or CCCP—the Russian initialism for the former Soviet Union. Like the old USSR, the “reliable and stable” foe that spurred much ORNL research in mid-to-late 20th Century, the world has passed much of the central campus by.

“The general idea of the project is to replace the oversized and outdated ORNL liquid and gaseous waste treatment systems, clear out the old facilities and clean up the underlying contaminated soils and groundwater, “ Dirk says.

Under the preliminary plans, nearly every structure in that area will be cleaned up, torn down and hauled away. The exceptions are the historic Graphite Reactor Museum, the steam plant, the Energy Efficiency and Renewable Energy facilities and the recently renovated 3500 complex. Nearly everything else in the area, including the 3025 complex, home of the Condensed Matter Sciences portion of the new Materials Science and Technology Division, and the fire hall, will be razed.

“Except for a few, these are all pretty old buildings that have reached the end of their service lives,” Dirk says. A historic preservation plan has been prepared and historic facilities and processes will be documented to preserve this area’s historical heritage and contributions to the Manhattan Project and nuclear and chemical sciences.

A trek from the west end of the X-10 site to the new east campus means passing through ORNL’s old downtown, although it is more reminiscent of an old industrial district. There are downright ugly buildings over here, an oddly rustic wooden structure with flaky paint over there, pipes protruding from the ground everywhere, and, all too often, the ominous magenta-and-yellow sign warning that radiological contamination is present.

Actually, the section from First Street to Third Street isn’t so bad. It’s the block with the fire hall, the “green door” machine shop and the old, empty ORNL cafeteria. Grass grows in lots of places, including where structures have already been removed.

|

ORNL’s Quonset huts, which helped inspire UT-Battelle’s modernization campaign, would be no more under the Central Campus Closure Project. |

But up on the hill is the “Winter Palace,” the shabby, drafty Quonset huts that housed the UT-Battelle transition team in the winter of 1999-2000. That experience ingrained in the new ORNL contractors the need for a general Lab modernization.

Bill Madia, the first Lab director from UT-Battelle, remarked that one of his greatest surprises on assessing ORNL in 1999 was the degree of deterioration of the physical plant.

Sure enough, cross Third Street going east and the scene becomes more grim. It’s the really old part of town—Isotope Circle, Reactor Row, the Gunite Tanks—the original X-10. Near the historic Graphite Reactor, which will stay, are the Oak Ridge Research and Bulk Shielding reactors, which will go. Here you find old machine shops, rock piles covering up contamination, relics from past projects and buildings that are deserted except for the occasional groundhog, braving it all.

How do you clean up something so massive and imposing? Dirk describes the plan.

“One thing you want to do is get your folks out of the way,” he says. “We need to move the people out of the area so we don’t have to work around them and so they aren’t potentially exposed to all the clean-up hazards. This ultimately protects people and saves the taxpayers money,” Dirk says.

So those currently in labs or offices in the central campus area are looking at an eventual move—with the first moves starting this year.

David Poker, the facility manager for Building 3025E—the home of the Condensed Matter Sciences group—says his tenants have been discussing moves for some time, with some going up to Chestnut Ridge and others moving to other Materials S&T Division facilities. But homes for most of the building’s residents aren’t ready.

Once that happens, “we’ll gladly accommodate the plans,” David says.

Once the labs and offices are vacated, the cleanup and demolition work is much simplified. But removing contaminated structures can be risky and must be done carefully. One proven approach is to work surgically. Dirk describes recent, successful projects.

“I was involved in the cleanup of the six large concrete underground liquid waste storage tanks in the South Tank Farm. They originally were going to put up a large containment building and dig the tanks and surrounding soil all up at a cost of hundreds of millions of dollars. Then we proposed something like arthroscopic surgery. We punched holes in the tops of the tanks and used robotic devices to clean the insides, and then filled them with concrete,” he says.

|

Contamination can be removed ‘surgically’ or with a process that resembles a face peel. |

The South Tank Farm is now usefully employed as a parking lot. Dirk describes another cleanup method, similar to a face peel.

“In the old contaminated Metal Recovery Facility (Building 3505), which was near the South Tank Farm, a DOE remediation team applied a rubbery coating to the walls of the cells, then peeled it off, removing most of the contamination and allowing them to use traditional nip-and-chip demolition techniques on the remaining reinforced concrete structure,” he says.

Dirk says hot-cell facilities are some of the trickiest to clean up. Several central campus hot-cell facilities have already been closed in a consolidation campaign, however, so work could begin fairly soon.

“The idea is to decontaminate buildings from the inside, where you already have containment in place, and then use typical demolition techniques to remove the remaining structure,” he says.

Excavation techniques will likely be applied to the Isotope Circle area of downtown—at the corner of Fifth Street and Central Avenue—a priority area because it contains significant subsurface contamination. Even after cleanup and demolition, future uses in that area will likely be restricted to parking lots, which would be welcomed by staff since it puts parking areas much closer to several heavily populated buildings.

ORNL has already seen one of those limited developments—the South Parking Lot—which sits on the site of four former holding ponds, now capped and sealed.

The CCCP is a long-term project; ORNL is supporting DOE’s Office of Environmental Management in doing the planning now for what will be a decade-long project. Beyond the technical and logistical challenges, there is also the funding hurdle. Similar cleanup projects abound throughout the DOE complex and, of course, there is only so much money to go around.

Project planners believe, however, that because cleanup projects at the East Tennessee Technology Park and in Melton Valley are in their latter stages, money for an X-10 cleanup could become available.

“The new east and west campus ORNL facilities are just next door, and the new programs those facilities are bringing to the Lab could help attract more cleanup dollars to the central campus project,” Dirk says.

Having a reason to clean up the area would be an advantage to getting the resources to do the job, and that reason could lie in the Oak Ridge Science and Technology Park, the industrial park that will be located in the central campus’s largely uncontaminated northwest corner. The cleanup project could turn that old quarter into valuable real estate once the outdated facilities are cleaned up and removed.

“We’re working this year on the mission-need documents and plan to start on the conceptual design next year. The work would ramp up in the 2007 to 2009 time frame, then really pick up steam during 2010 to 2015, and wrap up by 2018. If you’re working here then, you’ll have a pretty clear view from the Graphite Reactor all the way to White Oak Creek,” Dirk says.

“We want to go after it as one big job where we can get people out of the way, have easy access, clean it up, and make the space available to do good things in the future, while preserving the historical significance of the great work done in ORNL’s past,” he says.

“It will be a marathon, not a sprint,” Dirk says.—B.C. ![]()

Six R&D 100 Awards span range of Lab’s research

Six R&D 100 Awards span range of Lab’s research

ORNL researchers and engineers have

won six R&D 100 Awards, presented each year by R&D Magazine in recognition of the year’s most significant technological innovations.

The six awards touch Lab capabilities ranging from energy efficiency to computational sciences to advanced materials. ORNL researchers were recognized for the following inventions:

|

Co-developer Jeff Muhs displays optical fibers for the Hybrid Solar Lighting System, one of this year’s six R&D 100-winning technologies. |

Hybrid Solar Lighting System, developed by Jeff Muhs, David Beshears, Duncan Earl, Curt Maxey, Melissa Lapsa, Wes Wysor, Christina Ward and Randall Lind of the Engineering Science and Technology Division, John Jordan of ORNL Creative Media and Sunlight Direct of Oak Ridge.

The system uses a roof-mounted solar collector and small fiber optics to transfer sunlight to top-floor hybrid fixtures that contain electric lamps. With a control system, the two light sources work in tandem by dimming the electric lights when the sunlight is bright and turning them up as clouds move in or as the sun sets. The result is a dramatic improvement over conventional approaches to bringing sunlight into buildings.

The technology reduces energy usage not only for lighting but also for cooling because of the system’s ability to block ultraviolet and infrared heat. Developers note that the savings can be dramatic, especially in areas of the nation blessed with abundant sunshine.

LandScan Global Population Database, developed by Eddie Bright, Phil Coleman, Amy King, Budhendra Bhaduri and Ed Tinnel of the Computational Sciences & Engineering Division.

LandScan is a high-resolution population distribution model. At a 1-square-kilometer resolution, LandScan has 25 times higher resolution than the next best global population database. This database is produced through an innovative, flexible and dynamically adaptable spatial model that refines the best available census data utilizing geographic information system and remote sensing technologies.

LandScan has become the community standard for estimating population at risk and is useful for coordinating disaster response, humanitarian relief, sustainable development and environmental protection. In addition to U.S. federal agencies, thousands of users worldwide in government, education, research and commercial sectors use the LandScan database for scientific analyses and policy decision support in numerous areas of international significance. LandScan was an instrumental tool used during rescue and relief efforts after the Indonesian tsunami in December 2004.

Metal Infusion Surface Treatment (MIST), developed by researchers from C3 International, assisted by staff from ORNL’s Materials S&T Division.

MIST can infuse up to 51 elements into the surface of metals and alloys, and then secures these elements with a thin-nanostructure coating. Metalworking tools and catalytic devices have been treated resulting in increased lifetime or higher performance of the products, and the MIST process can be performed on site. In tests on cutting tools, MIST has yielded lifetimes 10 times better than conventional coatings.

NanoFermentation, developed by Tommy Joe Phelps of the Environmental Sciences Division, Lonnie Love of the Engineering S&T Division, Adam Rondinone of the Chemical Sciences Division, consultant and former ORNL researcher Bob Lauf and post-doctoral research fellows Yul Roh, Chuanlun Zhang and Ji-Won Moon.

NanoFermentation represents a fundamentally new approach for producing extremely fine, uniform and highly crystalline powders useful for magnetic media, ferrofluids, xerographic toner, catalysts, pigments, water treatment and coatings. The inventors believe that by making tailored nanomaterials available in economic quantities, their process will help stimulate interest in the development of new applications and eliminate a roadblock that has prevented the field of nanotechnology from reaching its potential.

TMA 6301 and TMA 4701, developed by Govindarajan Muralidharan, Vinod Sikka, Phil Maziasz, Neal Evans, Michael Santella and Christopher Stevens of the Materials S&T Division, Duraloy Technologies and Nucor Sheet Mill Group.

The two new heat-resistant cast austenitic stainless steels, with improved durability and lifespan at higher maximum operating temperatures, have been developed using a computer-aided design methodology. Use of the novel methodology reduced the time required for the development of new alloys from the six to 10 years typically needed with traditional trial-and-error methods to about three years. The new alloys will be used in various industrial equipment applications in the heat-treatment, steel, chemical, and petroleum industries. Since these alloys can be used at higher temperatures for longer times, energy savings and cost savings will be realized due to improved efficiency afforded by higher operating temperatures and increased component lifetime.

Trane CDQ, developed by Jim Sand, formerly of ORNL’s Engineering S&T Division, in collaboration with the Trane Company.

Trane CDQ controls the ambient air to a desired 45- to 60-percent relative humidity, which is important for libraries, schools, offices and, most importantly, hospitals. Because regulating humidity limits the spread of infection, the CDQ can maintain the needed moisture content as well as function more efficiently than its competition. Medical institutions, including St. Vincent’s Hospital in Alabama and Franklin Memorial Hospital in Maine, have installed the device. Unlike other air conditioning/dehumidifying units, the Trane CDQ effectively controls the humidity without adding heat to the system.—Reported by Ron Walli and Ashley Yeager ![]()

|

Old cars grace new campus

Old cars grace new campus

June 29’s Club ORNL Vintage Auto Day Display featured clear skies, free food and 43 classic cars.

The biggest draw was Steve Marschman’s 1988 Ferrari Testarossa. The car’s appeal has a downside, however. Steve said that he doesn’t drive it much because it “attracts flies”—people wanting to test their car’s performance against the Ferrari’s flat-12 engine.

“You can’t drive down Kingston Pike without some kid in a Honda Civic wanting to race,” Steve said.

Next to Marschman’s Ferrari was Jerry Gray’s 1970 Volkswagen Beetle. “That’s high budget there,” Jerry said, pointing to the Testarossa. He then motioned toward his car and said, “This is low budget here.”

One car of questionable vintage was David Christen’s 1973 Mazda RX-3. “I’m not sure it qualifies as vintage,” David said, “but it’s old enough.”

|

Tail-fins, as evidenced by this 1957 Chevrolet, were definitely “in” for June 29’s Club ORNL Vintage Auto Day Display. Forty-three cars ranging from the ’30s to the ’70s were showcased on the new east campus. |

The Mazda did have a unique attribute among the cars at the show—a rotary engine. David said that he has several old Mazdas with rotary engines that he likes to mess around with, including a 1974 pickup truck.

Earl McLemore’s 1973 Camaro was certainly vintage. However, he altered the concept of the car show, merging it with a swap meet.

A sign in the car’s window said, “For sale or trade for flat bottom boat.”

Ed Hagaman’s 1959 Chrysler Crown South Hampton undoubtedly claimed the title of the biggest car in the show. One passerby referred to it as coming from the era of yachts, and it did not fit into the 18-foot-long allotted parking space. Ed had to park it perpendicular to the curb up on the sidewalk.

“It’s 21 feet long,” he said, “That’s a big car, especially for a two-door.”—Charlie Smith

Trace your gene history

Trace your gene history

We may not look the same, and we may not talk the same, but we do have one commonality—we all came from ancestors who left Africa about 60,000 years ago. That was Gyan Bhanot’s central theme on June 8 in a Physics Division seminar.

That migration is old news. The exciting news, says Bhanot, is that by using mitochondrial DNA, or mtDNA, obtained through a cheek swab, he and his colleagues can trace an individual’s ancestry. Through computer analysis, the scientists can trace your ancestral history, as well as where your ancient relatives migrated when they left Africa.

The work is part of the National Geographic and IBM Genographic Project. Bhanot and his group are responsible for analyzing the “mtDNA pages” and looking in the genome for the mutations, or lack of them, that depict our species’ migratory history.

Scientists may be able to identify and tag ethnicity-based diseases and identify individuals who might have a higher risk for specific illnesses like breast cancer if they can sequence more genomes, Bhanot says.

The project needs more sequences from indigenous people such as Australia’s aboriginies, but the funding to reach these populations is scarce. Bhanot is not discouraged.

“You can participate yourself,” he says, “And while you’re paying for the information, a part of that money pays for them, the indigenous people, to be sampled too.”—Ashley Yeager

SensorNet test on-site

SensorNet test on-site

The ORNL campus gives SensorNet researchers a diverse, controlled environment for testing innovative ideas, David Resseguie of the Data System Science and Engineering group says. In fact, one such test is going on this summer on the east campus “quad.”

Resseguie envisions the campus as being a test bed for sensor-related technologies before they are implemented at SensorNet test sites at military bases or ports, avoiding major disruptions to the system.

Current testing in the east campus quad uses a Vanderbilt-developed tracking system, an operating system developed at UC Berkeley and ORNL radiation detection tools and cameras to track nuclear weapon-wielding targets.

The system tracks targets like a global positioning sensor, except that it has wireless sensors instead of satellites.

The SensorNet team followed the movements of an individual carrying a simulated dirty bomb throughout Vanderbilt Stadium during tests in April. This summer they are adding more capabilities to the system including the ability to shadow multiple targets.—Charlie Smith

Strides toward biomolecular imaging

Strides toward biomolecular imaging

The biological research community stands to gain new analytical tools thanks to work from the Materials S&T Division’s Low Dimensional Materials Physics group.

The work for the first time demonstrates that piezo-response-force imaging is possible in aqueous and other liquid environments, a key step in developing this technique for applications in soft condensed matter and biological systems. Aqueous environments, required for living cells, were believed to be incompatible with electromechanical imaging because the electrically conductive liquid interferes with the process.

In work recently described in Physical Review Letters, the ORNL team led by Brian Rodgriguez overcame the problem by using high-frequency biases to probe the sample surface, which reduces both the damping effect on the probe’s cantilever and interference of liquid conductance. The team achieved 3-nanometer resolution by controlling the conductivity of the solution.

“This represents an intermediate step for the mechanical imaging of biomolecular systems, says team member Sergei Kalinin. “Brian is first person to make it work.”—B.C.

Ashley Yeager and Charlie Smith are interns from the University of Tennessee’s science communication program.

—Reported by Bill Cabage |

Retirement reality: Fill financial gaps with savings now

Retirement reality: Fill financial gaps with savings now

by KATHRYN COGAR |

Current events, both national and local,

reveal powerful lessons learned about the reality of retirement; namely, a need for a major change in thinking about retirement and sources of income during retirement years

On June 22, hundred of retirees attended a public meeting originally scheduled to explain DOE’s proposed changes in pension and medical plans. A few days before the meeting, the changes were postponed (see sidebar). With the implementation delayed, the focus of the meeting shifted to the retirees’ concern over their pensions and the lack of adjustments to their pension benefit.

DOE representatives outlined the agency’s position that pension and medical reimbursement costs have increased to the point where research and other program funds will be impacted. Like the automobile industry and others across the nation, DOE says it cannot continue to increase its liability for retirement programs at the expense of its core business.

|

The simple truth is that fixed income from Social Security and pension plans may not be enough to live on in retirement. |

Taken together, the combined message from retirees and DOE is that reliance on pension benefits as the main source of retirement income is no longer an appropriate strategy.

Even though current employees were excluded from the announced changes in DOE’s pension and retirement policy, they would do well to heed the message: The simple truth is that fixed income from Social Security and pension plans may not be enough to live on in retirement.

Current retirees, particularly those over age 75, depend primarily on pension benefits and Social Security for income, augmented by any balance in the company savings plan and any personal savings and investments. Defined-benefit pension plans generally pay a fixed or defined benefit amount, which is based on the employee’s salary at the time of retirement.

The ORNL pension benefit replaces about 42 percent of your averaged highest salary (calculated by one of three formulas) for someone with approximately 30 years of service. The employer’s legal obligation is to pay this fixed amount over the life of the employee (and a spouse benefit if spousal option is elected). There is no requirement for the employer to provide periodic adjustments or modifications to the pension benefit. Private employers rarely make adjustments.

So, while medical costs increase, the cost of gas skyrockets and the overall cost of living goes up, the amount of income from the pension plan will be the same 20 years from now as it is on day one of retirement. And therein lies the need for a change in retirement strategy.

The good news is that we are all living longer. The bad news is that we need to be able to support ourselves during our extended lifespan. These “extra” years come at a time when we are least able to work and earn income, which means we need to stockpile even more money while we are able to work, earn and save.

The way we manage debt has changed. Pension and social security income alone may have been enough to fund retirement for our parents and grandparents, largely because they had no debt when they quit working. Today, many people max out their credit cards, refinance their homes and spend the equity so that at retirement they still have a large burden of debt to pay down. Though financial planners have previously stated that in retirement only 70 to 80 percent of your current income is needed, the reality is many of us may need 100 percent of our working income just to meet our monthly expenses as we move into retirement.

Medical costs continue to rise across the nation, and while this impacts everyone, it has a magnified impact on retirees, simply because they require more medical care and often at a more expensive level of services and procedures. Inflation and market economics further diminish the buying power of fixed, retirement income. As the costs of food, fuel, goods and services increase, more of those limited, fixed dollars are required to cover basic living expenses.

Coupled with the uncertainty around the future of Social Security, it’s obvious that a company pension can meet only a portion of total retirement needs. Employees today have a potentially devastating funding gap unless they get serious about saving for retirement.

The first step is to save rather than spend. Bass boats, motorcycles, new cars and exotic vacations don’t pay the bills and all too often increase the debt burden. That same money, used to pay down debt or build personal savings, becomes instead a long-term asset that can be a major source of income in retirement.

ORNL encourages saving by offering a 401(k) savings program to all employees. Although we have a high rate of participation (85.87 percent compared to the national average of 75percent) and nearly all contribute enough to earn the company match, most employees are not saving enough to fill the retirement income gap. The single most effective strategy available to employees is to save as much as possible, as soon as possible in the 401(k).

Thanks to tax deferral and the time value of money, the earlier you contribute, the fewer dollars are needed to build an adequate nest egg. Keeping in mind that retirement may last for 30 years or longer, employees and recent retirees as well should invest as aggressively as reasonable, based on personal circumstances. Regardless of when you retire, someone who can wait 15 years before making withdrawals should invest more aggressively than someone who needs the money in the next 5 years.

Retirement planning is not easy. It requires recognition and acceptance of personal responsibility for a future full of unknowns. It requires discipline, determination and resolve in the face of a constant barrage of demanding needs, wants and wishes. Ultimately, however, it can result in a future that you can approach with anticipation and peace of mind, knowing that you have the income to enjoy your retirement years.

Kathryn Cogar is ORNL Benefits’ communications manager. ![]()

Cruising, golf, Vols

Cruising, golf, Vols

Lab retirees can check Club ORNL on-line

The Club ORNL calendar includes a variety of events geared to a wide range of budgets and tastes. Lab employees can check out the club’s Website at home.ornl.gov/general/clubornl/ for more detailed information on upcoming events.

September: Fall golf tournament; details will be announced later.

|

|

October 26: ORNL’s Fall Festival and Craft Show

November 4: Vols vs. LSU. Club ORNL has 500 tickets to see the Volunteers play LSU – cost $50. There will be a sign-up period via a special Website for two weeks in September; once the sign-up period is over there will be a random computer drawing to select who gets the tickets. Tickets will be limited to two per employee. During the sign-up, retirees will contact Nancy Gray to add their names to the list.

December 3-4: The road trip to Asheville and the Biltmore House is sold out! Trip details will be e-mailed to the lucky trekkers.

Retirees: Sign up for the Website

ORNL retirees can now see upcoming Club ORNL events and information on the Web. Go to http://www.ornl.gov/adm/clubornl_signup.shtml and follow the instructions to create an account. Once your account has been approved, you’ll be able to keep up with Club ORNL on-line. Nancy Gray (576-9479, graynl@ornl.gov) is the club’s point of contact for retirees. Club ORNL information also will be available at each month’s Friends of ORNL meeting.. ![]()

New Staff

Members

New Staff

Members

Sadaf Roohi Alam, Computer Science & Mathematics Division

Hailemariam Ambaye, Xiaodong Tao and Cornelius Donahue Jr., SNS Experimental Facilities Division

Larisa Marie Brass, Communications & External Relations

Madhu Sudhan Chinthavali and Benjamin Kenneth Sovacool, Engineering Science & Technology

Timothy James Gillespie, Brian James Sparks, George Martin Stephens Jr., Nuclear & Radiological Support Services

Brandy Elaine Goldston, Facilities Management

Gregory Scott Lawson, Curtis Lynn Phibbs Jr., Thomas Alan Justice, Roger William Housman Jr. and Charles Cory Peters, SNS Accelerator Systems

Hakki Sarp Oral and Richard Makia Minich, National Center for Computational

Sciences

Melanie Ann Paquette, Laboratory Protection

Stephen Randall Metheney, Craft Resources

John Richard Miller, U.S. ITER Project

Bruce Edwin Wilson, Environmental

Sciences

Anita Katherine Parton, Fabrication Division

Battelle honors three as distinguished inventors

Battelle honors three as distinguished inventors

|

||

Smith |

Hsu |

Moorehead |

Three ORNL researchers have been honored as Battelle Distinguished Inventors for obtaining 14 or more patents during their careers at the Laboratory.

The honorees are:

John Hsu with 15 patents that deal primarily with electric motors and their associated components and drive packages, energy conversion machines and thermal management of vehicle systems and components. John works in the Engineering Science & Technology Division.

Stephen Smith with 14 patents related to pulse transmission and receiving, monitoring of fluid pressures and flow abnormalities in gasses, monitoring machine performance and performing spectral analysis on alternating currents in motors. Stephen works in the Engineering Science & Technology Division.

Arthur “Artie” Moorhead with 14 patents relating to processes for fabricating, joining and strengthening ceramics and other materials. These include development of filler metals for brazing of ceramics, processes and methods for fabricating ceramics and articles from particle-based materials and methods for joining carbon-carbon composites to

metals. Artie recently retired from ORNL.

The honorees join an elite group of inventors recognized by Columbus, Ohio-based Battelle from the scientific ranks of its own labs and the federal labs it helps to manage. Battelle has bestowed the honor on 42 inventors, 18 of them from ORNL.—Mike

Bradley ![]()

Sayler, Smith take joint institute for biological sciences posts

Sayler, Smith take joint institute for biological sciences posts

As construction is about to begin on the ORNL and the University of Tennessee Joint Institute for Biological Sciences, two major positions for the facility have been filled—its director and a Governor’s Chair of Excellence.

|

Sayler |

Gary S. Sayler, Beaman Distinguished Professor of Microbiology, Ecology and Evolutionary Biology at UT, has been appointed the joint institute’s first director. Sayler will lead the development of the joint institute’s R&D program, including staffing, expanding its programmatic funding base and establishing collaborations between the Laboratory and UT and with other research institutions worldwide.

“Dr. Sayler’s scientific credentials, vision and previous leadership experience make him the ideal person to lead JIBS during this important phase for the institute,” says Reinhold Mann, ORNL associate Laboratory director for Biological and Environmental Sciences.

The Joint Institute for Biological Sciences program represents an approximately

$15 million investment by the state of Tennessee and UT in joint research and development in biosciences and biotechnology at UT and ORNL. Sayler’s appointment is effective July 1.

|

Smith |

Meanwhile, Tennessee Gov. Phil Bredesen and UT President John Petersen have announced the selection of Jeremy Smith as the first UT-ORNL Governor’s Chair appointee. Smith is currently chair of computational molecular biophysics at the University of Heidelberg, Germany. Smith’s appointment will be to the Joint Institute for Biological Sciences.

Smith’s research interests involve understanding biological molecules such as proteins using computer simulation and neutron scattering experiments. His research is interdisciplinary, involving the fields of chemistry, physics, computational science and biology. Smith is a leading expert in applying neutron scattering to important biological questions and will be among the first scientists to perform research using the Spallation Neutron Source.

“Much of today’s research cuts across traditional boundaries such as biology, physics and computation,” says ORNL Director Jeff Wadsworth. “Jeremy Smith specializes in bringing these fields together and is an ideal choice to help us tackle some of science’s toughest challenges.”

The UT-ORNL Governor’s Chair program is designed to attract exceptionally accomplished researchers from around the world to boost the efforts of the joint institutes shared by the university and the Laboratory. Governor’s Chair scientists will have joint appointments as tenured UT faculty and distinguished ORNL research staff. The state of Tennessee and ORNL are investing more than $20 million to recruit and fund the

positions.

The Joint Institute for Biological Sciences is one of four state-funded ORNL and UT joint institutes. One, for computational sciences, is already complete on ORNL’s east campus. Construction on the biological sciences facility starts this summer on ORNL’s west campus. The Joint Institute for Neutron Sciences will be located on Chestnut Ridge adjacent to the SNS and the Joint Institute for Materials Sciences will be located on UT’s Knoxville campus.—B.C. ![]()

ORNL People

ORNL People

ASM International has named Hua-Tay Lin a 2006 Society Fellow, honoring his contributions in the field of materials science and engineering. Hua-Tay, a senior researcher in the Materials S&T Division, will be inducted at the October ASM Awards dinner.

The Materials S&T Division’s Elbio Dagotto has been named to the Solid State Sciences Committee of the National Academy of Science will help advise the Board on Physics and Astronomy

Paul Becher, UT-Battelle corporate fellow and member of the Materials S&T Division, is recipient of the American Ceramic Society’s 2006 Edward Orton Jr., Memorial Lecture Award. This award is the highest given by ACerS to a lecturer in the field of ceramics.

Amit Goyal has received a 2006 American Society of Metals-Indian Institute of Metals Lectureship Award. ASM-IIM visiting lecturers are ambassadors-at-large of ASM International to the materials community in India. ![]()

Bill Cabage, editor, ORNL, 865/574-4399 (cabagewh@ornl.gov)

Deborah Barnes, associate editor, 865/576-0470 (barnesds@ornl.gov)

ORNL office: P.O. Box 2008, Oak Ridge, TN 37831-6146, Building 4500-N, Room K-238, MS 6266

News Deadlines

DOE inspector general hotline: 1-800-541-1625

[an error occurred while processing this directive] [an error occurred while processing this directive]