|

Number 84, December 2006 |

New way to weld

New way to weld

ORNL team adds laser tech to expand the reach of a new welding technique

ORNL’s Materials Joining group is poised to create a stir in the world of welding. Corporate Fellow Stan David’s Materials S&T Division team has improved a new method of joining materials—developed as recently as 1990—called friction-stir welding.

Welding, which is usually considered a mature technology, is the subject of unrelenting research toward improving ways to join ever more complex materials under increasing quality demands. Welds are often the most common failure points on structures or in systems, so welding technologies are closely scrutinized and researched. Industries commonly use arc, plasma-arc, laser, electron beam and resistance welding. All of these involve melting and fusing the parts to be joined.

“Friction-stir welding, a recently invented and novel joining process, has gathered lots of attention worldwide because of its ease in joining materials without melting, avoiding problems we see in conventional welding,” Stan says.

In conventional welding, two metals are heated until they melt and fuse together. It sounds simple, but the melting often results in structural defects that weaken the joint. Researchers have sought welding technologies to deal with almost limitless variables in materials and conditions.

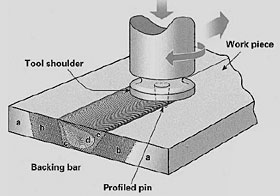

Developed at The Welding Institute in England by Wayne Thomas—a frequent visitor to ORNL—friction-stir welding is a solid-state process. That means, as Stan explains, the metals are heated and hot-worked enough to join without actually melting.

|

|

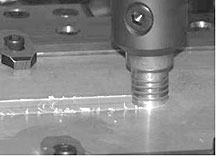

Here’s how it works: A rapidly spinning tool with a pin is plunged into the seam between the two metal parts to be joined. The frictional heat generated softens the metal but doesn’t melt it. The spinning stirs the two metal parts together into a perfect bond. In a cross section of two aluminum plates friction-stir welded together, it is difficult to see even where the joint is.

FSW works great on metals with low melting temperatures, like aluminum. Applying the technique to welding high-melting-point metals is where ORNL comes in.

“The challenge is to extend this technology to hard, high-temperature materials such as steel and titanium. This is of great interest to the energy, automotive and petrochemical industries, to name a few,” says Zhili Feng of the Materials Joining group.

Zhili has led a multidisciplinary team in expanding the friction-stir technique and also in real-time, in situ analysis of friction-stir welds using neutrons (see sidebar).

Friction-stir welding’s business end is a metal-tool tip, or pin, that spins its way through the metal pieces, joining them. Think of two bricks of vanilla ice cream placed against each other and a mixer’s beaters plowing through them, homogenizing them just enough so that they join, without actually melting the ice cream.

Because welding is an expensive step in many manufacturing processes, laser-assisted friction-stir welding has revolutionary potential. |

|---|

“We can develop high-temperature tools that work from materials such as tungsten-rhenium or iridium alloys, but they quickly wear out,” Zhili says.

ORNL’s answer is a hybrid process—they have combined another welding technique, laser welding, with the friction-stir process as a heat source to preheat the metal parts to be joined. This helps to soften the metal and save wear on the tool.

“The tool doesn’t have to work as hard,” Zhili says. “It reduces load on the tool by 50 percent.”

Stan says because welding is an expensive step in many manufacturing processes, the new technology has revolutionary potential.

“In the auto industry, cars have more than 4,000 resistance spot welds, which is cost-intensive because the copper electrode wears out,” he says. “Automotive companies are very interested in extending this process to friction-stir spot welding.”

The group’s Mike Santella has been working with the automotive sector investigating friction-stir spot welding.

Another advantage of the process is that, because the process doesn’t melt the metal—it just gets hot enough to hot work and “stir” it—changes to the materials’ properties are minimized. A variation known as friction-stir processing can modify surface characteristics of castings by removing porosity and refining grain structure, thus improving metal-fatigue life cycles tenfold.

“Welds are often thought to be the weakest point in a structure,” Stan says, “but instead of weakening, the weld can actually be the strongest point because of the reworked grain structure in friction-stir welds.”

|

|

The business end of a friction-stir welding tool plows through a sample. The process avoids changes in materials’ properties caused by melting. |

FSW is catching on. With increased applicability to metals such as titanium and stainless steels, the petrochemical industries (think of joined pipelines) and aerospace industries (a corporate jet has replaced all rivets with stir welds) are taking up the technology. The Space Shuttle’s external fuel tank, a series of joined cylinders, has gone to a less heavy aluminum-lithium alloy, joined with friction-stir welds. The Electric Power Research Institute is investigating using laser-assisted FSW to repair the blades in power-plant turbines.

Interest from industry and groups such as The Welding Institute has helped the Materials S&T Division pursue the technology. Former Metals & Ceramics Division Director Everett Bloom helped put together funding from Basic Energy Sciences, Energy Efficiency and Renewable Energy and Fusion Materials programs to purchase a state-of-the-art, $750,000 FSW station, housed in Building 4508’s high-bay area.

Recent work at ORNL on the development of a hybrid laser-friction-stir welding process has been highlighted in ASM-International’s journal Advanced Materials & Processes in an article by Zhili Feng, Stan David, Alan Frederick, Oleg Barabash and Joey Edgemon.

With the improved techniques, welding is poised to enter the realm of nanoscience.

“As you melt metals, you destroy original grain structure in the metal,” explains Stan. “In FSW, as the hot-worked material recovers and recrystalizes, new grains are created. The trick is to avoid grain growth. If you can avoid that, you get nanoscale grain structures.”

The group has already produced bulk nano materials, such as nano structured-titanium, with FSW.—B.C. ![]()

Space reactor’s mission reaches earthly closure

Space reactor’s mission reaches earthly closure

|

|

Workers pack up the TSF-SNAP reactor in 1973. It wouldn’t be unpacked until 2006. |

ORNL, which once built nuclear research reactors, this summer took one of its creations apart, closing the books on an experimental program that produced valuable data on space flight and radiation shielding.

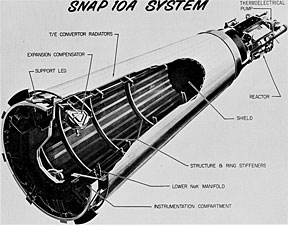

The TSF-SNAP reactor was small, and for good reason: It had to be compact and light enough to be launched into space. It was one of the reactors designed for NASA’s Systems for Nuclear Auxiliary Power program by Atomics International, a California firm, and built at ORNL.

The cooler-sized reactor and its squid-shaped assembly—the sodium-potassium, or NaK, cooling system and heat transfer system—were small enough to fit into the nose cone of a rocket.

One SNAP reactor actually made it into space in 1965. Although an electrical fault disabled it after just 43 days, the spacecraft and its otherwise perfectly good reactor remain in polar orbit. ORNL’s SNAP was never meant to fly, but it did log experimental hours at the Tower Shielding Facility, the tall towers located in a hollow off Highway 95 and visible from Interstate 40.

The TSF’s towers enabled radiation sources to be hoisted into the air, where realistic data relevant to projects such as the nuclear-powered airplane could be gathered. Other shielding experiments, including TSF-SNAP, stayed near the ground in specially shielded areas.

TSF-SNAP’s mission was to confirm the early computer models of radiation dose. Radiation was a concern, of course, to a potential aircraft crew. It also fries electronics, which was the main concern with unmanned spacecraft. TSF-SNAP provided a wealth of information on projects that included liquid-metal breeder and sodium-cooled reactors.

“In space you use radiation to dissipate heat, so they had a large radiator structure behind the reactor, which was in the rocket nose. A lithium-hydride shield was located at the base of the reactor to maximize the shielding shadow. The ORNL research was to determine how well the shield reduced the dose,” says the Nuclear S&T Division’s Fred Peretz.

When its mission ended in 1973, the reactor, with its highly enriched uranium (HEU) fuel inside, was reconfigured for storage, crated up and moved to Y-12, where it was hoped a use for it might someday arise.

None did. More than 30 years later, ORNL was asked to propose a project to bring the reactor out of storage to ORNL, recover the HEU fuel and dismantle the equipment. Y-12 funded the project as part of its campaign to clean out its warehouses of disused nuclear equipment, especially any that contained what is classified as special weapons material—the HEU.

|

|

A SNAP reactor launched in 1965 remains in orbit. Although the craft was disabled by an electrical malfunction, the reactor is probably still in good shape. |

“The HEU Disposition Program Office designated the HEU as surplus designated for downblending,” says Fred, who led the project. “Y-12 considered ORNL better suited to such a unique job and asked the Lab to dismantle and package the reactor and dispose of the NaK.”

TSF-SNAP’s “disposition” presented several technical challenges.

“Criticality was the biggest challenge,” Fred says. “The reactor still had the HEU fuel in it. It had to be handled precisely.”

Also of concern was the NaK coolant, which is highly reactive when exposed to water—it fizzes and burns and explodes. Nevertheless, NaK is considered an ideal coolant for space reactors because it does not have to operate under pressure.

The first order of business was trucking the reactor from Y-12 to ORNL. On June 24 the crate containing the reactor assembly was loaded onto a low-boy trailer and trucked at a security-escorted 25 mph down Bethel Valley Road, which was closed to traffic “to ensure everything on the road was abiding by the

25 mph speed limit,” Fred says.

Aside from drawing wide-eyed stares from a couple of fishermen, the TSF-SNAP’s move down Bethel Valley went without incident. |

|---|

The final destination was Building 3525, the High-Rad-Level Examination Laboratory, where the facility’s operations team was to disassemble the reactor. Aside from drawing wide-eyed stares from a couple of fishermen, the procession down Bethel Valley went without incident.

ORNL called in a consulting firm, Creative Engineers, Inc., which specializes in handling NaK, to teach the ORNL team how to drain the 8.4 kilograms of reactive coolant. The residual NaK was then neutralized by converting it to hydroxide. That process took about two minutes.

To be certain, however, “they ran the process for an obviously excessive 24 hours,” Fred notes.

When it was packed up, the reactor was fitted with a criticality safety sleeve that replaced a beryllium reflector, which prevented the reactor from going critical. Once back at ORNL, workers removed the heat-exchanging system and then replaced the original safety sleeve with one that didn’t cover the reactor head. Then they opened the head and removed the fuel elements, which were then packaged and sent back to Y-12.

By September, the drained NaK was converted to caustic. The pieces were packed up and are destined for a low-level waste disposal area.

“The reactor ran at very low power, so the hardware was barely activated. The reactor itself was lightly used and could have made a good university reactor, but never was,” Fred says.

As projects go it was comparatively small, but the numerous elements that went into disassembling the nuclear reactor, regardless of how compact, involved the efforts of multiple Lab organizations, including the Nuclear S&T Division, the Nonreactor Nuclear Facilities Division, the Facilities and Operations Directorate and all divisions of the Environment, Safety, Health and Quality Directorate. Leo Holland, who was a mainstay at the Tower Shielding Facility in its heyday, was called in to advise and help write procedures. The National Nuclear Security Administration funded the work.

The TSF-SNAP’s fuel will be downblended for use as commercial reactor fuel. If the fate of the reactor seems a little ignominious, the crew who worked on the project—particularly the nuclear engineers who missed the reactor era—appreciated the opportunity.

“The final work with TSF-SNAP re-acquainted ORNL staff with all of the project elements associated with working with space reactor assemblies. It provided practical experience in the handling, cleanup and disposal of the NaK coolant,” Fred says.

“All of us that were privileged to be part of this activity took away much from the experience and will never forget it.”—B.C. ![]()

AAAS elects Thundat fellow

AAAS elects Thundat fellow

|

|

Thundat |

Thomas Thundat has been elected a fellow of the American Association for the Advancement of Science. Thomas, a member of the Biosciences Division and a UT-Battelle corporate fellow, is noted for research involving sensor technology and weapons detection.

The AAAS Council cited Thundat’s “pioneering work in developing a novel class of sensors for molecular recognition using nanomechanical sensor platforms.”

Microcantilevers—microscopic devices that can be used to detect a number of substances including trace quantities of chemical and biological agents—are one application of nanomechanical sensors.

One of Thomas’s concepts uses the microcantilever technology to detect minute amounts of TNT, which could be applied to both national security missions and the reclamation of former battlefields and war zones.

His work with microcantilevers was cited when he received, in 2004, the Southeastern Section of the American Physical Society’s Jesse W. Beams Research Award for research excellence. He was also listed as one of Scientific American magazine’s “Scientific American 50 Award” winners that year.

In 2000 Thomas was a finalist for the Discover magazine awards. His work has also received R&D 100 and Federal Laboratory Consortium awards.

He and his wife, Darilyn, have two daughters, Rachel and Tess, and a son, Jonah. The family resides in west Knoxville.—B.C. ![]()

Community spirit stays strong

Community spirit stays strong

|

|

Associate Lab Director Michelle Buchanan (center left) joined Angel Tree donors and committee members at the gift drop-off. |

ORNL staff members continued their world-class giving spirit into the holidays. Team UT-Battelle capped a busy fall with another successful Angel Tree program and strong participation in local fundraisers for a variety of causes.

Employees quickly picked clean this year’s ORNL Angel Tree, in which staff members selected the names of needy children and supplied gifts. Approximately 240 kids who otherwise didn’t have great holiday expectations will get presents. Staff members were also generous in stocking an Angel Tree account set up at the ORNL credit union, which accrued more than $1,100, says team captain Angela Raby.

Captain Nancy Daily and more than 40 volunteers collected over $13,000 for the Five-County Alzheimer’s Memory Walk. The Team UT-B also won the team award for the September 30 event; Nancy received the top individual award.

Team UT-Battelle fielded a big corporate team for the Komen Race for the Cure for breast cancer, which jammed the streets of downtown Knoxville on October 29. Captain Cathy Cheverton and 237 volunteers raised $8,000, with another $300 donated by UT-Battelle. Team UT-B was the largest corporate team for the sixth straight year.

Those events came in addition to another successful United Way campaign for the Lab, which surpassed the $800,000 goal, and to this year’s Community Shares campaign, which chairman Mac Post says increased both participation and donations toward a variety of area environmental and social justice

organizations. ![]()

ORNL People

ORNL People

An Oak Ridge High School team won the overall team award in the National Siemens Competition at New York University on December 4. Scott Horton, Scott Molony and Steven Arcangeli will share a $100,000 prize for their winning project, “Linking Supercomputing and Systems Biology for Efficient Bioethanol Production.” Scott Horton is the son of Nanoscience Center Director Linda Horton and the Materials S&T Division’s Joe Horton. All three students worked with Nagiza Samatova and Chris Symons in a summer research program in ORNL’s Center for Computational Sciences.

Ron Graves in the Engineering S&T Division’s Engines and Emissions Research Center has been elected a distinguished fellow by the Society of Automotive Engineers.

Pat Parr, ORNL’s natural resources manager, received the Robert E. Gonia Leadership Award for Loudon County at the recent East Tennessee Regional Leadership Forum.

Materials S&T Division’s Claus Daniel, a current Wigner fellow, received the Dr. Eduard Martin Prize from his former university, the Saarland University in Germany. The prize is given to recognize the best young scientists and outstanding dissertations each year.

David Greene, a corporate fellow and member of the Transportation Policy & Planning group in the Engineering S&T Division, has received an appointment as a member emeritus of the Transportation Research Board Committee on Alternative Transportation Fuels.

Materials S&T Division Director Steve Zinkle has received the American Nuclear Society’s 2005 Outstanding Achievement Award from the American Nuclear Society.

The ANS also presented the MSTD’s 2004 Literary Award to a paper by the Materials S&T Division’s Thak Sang Byun and Kenneth Farrell, titled “Plastic instability in polycrystalline metals after low temperature irradiation.” The paper appeared in Acta Materialia.

Lance Snead, Steve Zinkle and D. P. White received the 2005 Literary Award for the paper “Thermal Conductivity Degradation of Ceramic Materials due to Low-Temperature, Low-Dose Neutron Irradiation,” which was published in the Journal of Nuclear Materials.

David R. Cole, Chemical Sciences Division, has been chosen a fellow of the Mineralogical Society of America for contributions to the fields of mineralogy, petrology and crystallography.

John Vitek of the Materials S&T Division received the Comfort A. Davis Lecture Award at the annual American Welding Society Welding Show and Convention John’s lecture was titled “Modeling is Great, So What?

|

Leave no manometer behind

Leave no manometer behind

No objects gain as much value as those rescued from the scrap heap. ORNL’s Metrology Lab has such a treasure—a Schwien manometer retrieved from K-25’s scrapyard and lovingly refurbished by technicians who appreciate good gear.

Manometers are mostly used to calibrate instruments that measure pressure, such as barometers and altimeters. ORNL’s manometer was purchased for K-25 in the 1960s for around $70,000. A similar instrument today would cost about $400,000. The instrument became disused after K-25 ended enrichment operations in the mid-1980s.

“I knew about it a long time ago,” says Bill Wright of the Quality Systems & Services Division and who once worked at K-25. “It was abandoned and was to be scrapped.”

Bill and Facilities & Operations’ Bob Quinn spirited the Schwien to ORNL and went to work on it. Somewhat resembling a telephone booth for very tall people, the manometer used a column of mercury and a precision jack screw to generate pressure signals for the calibration of pressure-measuring devices.

|

|

Their baby: Bob Quinn (left) and Bill Wright with the manometer they rescued and refurbished. |

It calibrated with an uncertainty of a mere 0.0002 inchs of mercury, a unit of pressure measurement. Bill and Bob retrofit a modern laser interferometer that reduces the uncertainty to 4 millionths of an inch of mercury.

“Bill’s expertise in laser interferometry and uncertainty calculations has resulted in the manometer’s performance exceeding the manufacturer’s specifications. It’s quite possibly the best performing Schwien manometer in existence” says the Metrology Lab’s Mike Duncan.

Now the Lab has an intrinsically precise instrument that’s so sensitive that its measurements must be corrected for variations in gravity, tidal forces and the speed of light. The manometer is directly traceable to SI units, which means its calibrations require no National Institute of Standard and Technology check.

It’s a fairly rare bird. Most major airlines own one for altimeter calibrations; the U.S. Air Force has two while the Navy has 20. And now ORNL has a top-notch specimen.

“Bill and Bob brought this dinosaur not only back to life but back to life with a vengeance,” says Mike.

Rare cosmic ice a possibility

Rare cosmic ice a possibility

Ice is ice, right? Well, no. Bartenders will tell you that cold, hard ice makes better cocktails than wet, sloppy ice. Now an international team of researchers that includes the Neutron Scattering Sciences Division’s Jaime Fernandez-Baca and Bryan Chakoumakos have postulated in the Astrophysical Journal that ice of a certain supercold temperature range may have had a bearing on planetary formation and even the emergence of life.

Scientists have theorized that “ferroelectric ice” could exist in the universe. “Ferroelectric” means that the protons typically disordered in the crystal structure of normal ice becomes perfectly arranged so they can produce a strong magnetic electric field. Neutron diffraction studies performed at the High Flux Isotope Reactor indicate that ferroelectric ice formation is possible at 57-66 Kelvin, which happens to be a temperature range found on the surfaces of Uranus, Neptune and Pluto.

“This finding has astronomical implications, as it has been proposed that the large electric fields that would be produced by ferroelectric ice are important in planetary formation,” says Jaime.

Principal investigator Hiroshi Fukazawa of the Japan Atomic Energy Agency believes the existence of ferroelectric ice may also play a role in the formation of organic materials.

The ice studied at HFIR contained an impurity that speeded up the transformation into ferroelectric ice that normally would take 10,000 years. Although, astronomically speaking, that’s just a blink of an eye, the impurity cut the process down to a more manageable several hundred hours.

Odds of more math articles increase

Odds of more math articles increase

ORNL Reporter doesn’t have enough articles about math. So when the outcome of the Ohio State-Michigan football game eerily matched that day’s winning Ohio state lottery number, we asked the Computer Science and Mathematics Division’s George Ostrouchov: “What were the odds of that happening?”

|

|

George replies: “If you are asking about the specific score 42-39 and specific number 4-2-3-9, a quick probability calculation gives (0.1)*(0.001)*(0.00019999) = 1.9999/100,000,000. That is about two in a hundred million! The football odds (the first two odds numbers) come from a 1970 paper on frequencies of football scores. This may be a little dated as the game has changed somewhat since then, but the frequencies are probably still not too far off. The lottery odds are exact as there are two drawings on that day: a binomial probability with a 0.0001 chance of success. They are independent so we multiply the probabilities.

“Now if you ask the question ‘What are the odds that the football score and the lottery number agree?’ the odds are much higher because we can now have any one of nearly 10,000 possible agreements. This is a bit more difficult problem to solve exactly, but we can get a ball park figure by assuming that a football score can be any two-digit number and they all have the same probability (not true but probably within a factor of about 10). Using a binomial argument we get about 0.0002 or about 2 in ten thousand!

“Another way to get an approximate answer is to treat the footbal score as fixed and ask what is the probability of matching it with one of two lottery drawings, which is again about 2 in 10,000.

“When we really think about this, the surprise is that the lottery and the score agree. It is not a great surprise that the score was 42-39. This is related to the so called ‘birthday problem,’ where we find that the probability of two people sharing a birthday in a room of 35 people is 0.81, surprisingly close to 1, yet to find someone with a specific birthday is much less probable. This phenomenon (many opportunities for a match) is a mathematical explanation for a relatively high probability of finding surprising coincidences.”

—Reported by Bill Cabage and Larisa Brass |

Sound footing

Sound footing

|

|

| In this newspaper photo from 1959, Nancy Markham, the child nearest the camera, is shown taking part in a class at the University of Tennessee’s Hearing and Speech Center. |

Early care, parents’ devotion keys to Markham’s triumph over hearing disability

Nancy Markham’s nearly three-decade career at ORNL is a triumph. It represents a victory over a disability— Nancy is hearing impaired. The term she prefers is “deaf.”

“I do prefer the term ‘deaf.’ I am proud of who I am,” she says.

Her lack of hearing hasn’t stopped her. Located in the Engineering S&T Division’s Business Management group, in addition to routine clerical duties Nancy serves as the Webmaster for the division’s internal Website and newsletter, handles quarterly dosimetry distribution, carries out ad-hoc secretarial projects, as well as training scheduling and tracking.

The outlook for Nancy’s having a productive career probably wasn’t rosy when her deafness presented itself shortly after her birth. Nancy’s mother noticed that she didn’t respond to sounds and sought help for her immediately.

Tests in Nashville showed that her impairment was caused by nerve damage and thus was probably untreatable. Doctors suggested taking little Nancy Swicegood to the University of Tennessee.

|

|

| Speicalized office tools, such as a text telephone machine, help Nancy Markham communicate in the office. |

“Beginning when I was about two years old, my mother took me to the UT Hearing and Speech Center for three days a week for four years. My mother drove to Knoxville from Harriman, giving up her time at home to spend more time with me,” Nancy says.

“I believe my parents’ getting help for me in early infancy has been to my advantage because it would have been impossible for me to communicate with others without ever hearing spoken language. I had to do the best I could with gesturing until I learned a more suitable way of expressing myself,” she says. “That is why it is important to start developing language earlier in life, especially in the life of a deaf child.”

At UT she learned to speak and how to differentiate between sounds, concepts that can be hard to fathom for those who have always been able to hear.

“It took a lot of practice to learn speech and to read lips,” she says. “ Sound was a new thing and I had to learn what it was before I could attempt to reproduce it. Also, it was a challenge to learn the vowels: a, e, i, o, u.”

Nancy entered the first grade at Tennessee School for the Deaf in Knoxville, where, during her 12 years as a student, she learned American Sign Language and how to speak.

With the communications skills acquired at TSD, she came to work at ORNL in 1977 as a typist. Technology—some old, some new—has helped her improve her productivity and ability to communicate with co-workers.

“In my office, I use a TDD (text telephone) machine. This is how the Tennessee Relay Center works: A person who is deaf, hard of hearing or speech-disabled types his or her conversation using a TDD. A Tennessee Relay Center communications assistant relays the message by reading it to the hearing person at the other end. The assistant then relays the hearing person’s spoken words by typing them back to the TDD user. Each call is handled in strict confidence and no record of the conversation is kept,” she explains.

“I have a Blackberry in case of emergencies if the secretary needs to contact me. The secretary sends an e-mail to my Blackberry and I can respond back to her with a text message,” she says.

(In fact, in this case “says” is a figurative term. Most of this Reporter interview was done through e-mail.)

Nancy has participated in several activities for deaf employees, including hosting TSD students as part of Job Shadowing Day. She has volunteered for the United Way, including the International Festival. Every Tuesday last summer Nancy had lunch with other ORNL employees who have taken the on-site sign language course to help them perfect their sign language skills. She has also been the guest speaker at an Affirmative Action Disability Conference in Atlanta.

In the 29 years that Nancy Markham has worked at ORNL, she hasn’t heard a sound. Her achievements, however, speak for themselves.—B.C. ![]()

Nancy recommends these Websites: Sorenson Video Relay Service, a free service for the deaf and hard-of-hearing community, www.sorensonvrs.com, and Knoxville Center for the Deaf, www.kcdtn.org/specialprograms.html.

New Staff

Members

New Staff

Members

Christine Goudy and Danny Clay McInturff, Materials Science & Technology

James Harold Kidder, Communications & External Relations

Sarah Anne Mears and Regina Parker Ford, Business & Information Services

Mark Allen Neal, Nonreactor Nuclear

Facilities

Michael J. Plaster, National Security

Timmy Alan Rivera, Craft Resources

Jared Quinn Windham, Legal

Donald Lee Blackburn, Safety Services

Jennifer Leigh Carpenter and Jennifer Tonzello Caldwell, Technology Transfer & Economic Development

Steven Myron Davis, Laboratory Protection

De-en Jiang, Chemical Sciences

Danny Wade Parker, Laboratory Protection

Sarah Jill Turner, Human Resources

Steven Brinson Bonnett, Audit & OversightLori Ann Frye, Neutron Scattering Science

Fredric Stephen Proffitt, Neutron Facilities Development

Xiaohui Cui, Computational Sciences & Engineering

Ignacio Diaz, Research Accelerator

Scott M. Hollenbeck, Center for Nanophase Matl’s Sciences

Paul Stephen Litherland, U.S. ITER

Letters

Letters

Many anecdotes and remembrances have been expressed following the death of my friend, Alvin M. Weinberg. [ORNL Reporter’s] article was an excellent summary about the ‘icon.’

However, I will always remember Alvin as my friend. He was a friend who cared deeply for others. I was made keenly aware of this fine quality in the summer of 1982, when I was so saddened by the loss of our son, Joey.

That summer I could always look forward to a frequent phone call from Alvin, any sunny day, to schedule a tennis match. Sometimes we played our matches at the Jackson Square tennis courts. As time passed, we “decided” that the soft courts at the Oak Ridge County Club were better.

Too fast the years slipped by and our singles matches kind of went by the wayside. But the doubles matches, with players like Mozell Bell and Dan Thomas, were just as delightful. There was no better way to spend a Saturday morning than playing tennis with Alvin. It was wonderful hearing him say, with great auricular enthusiasm, “Great shot, Eva!” I will miss him immensely.

E.M. Wike, Oak Ridge

‘Unbelievable.’

‘Unbelievable.’

Computing pioneer returns for visit to ORNL, recalls computing in the ’50s

Even the pioneers of computational science

can be astonished at the power of modern supercomputers.

“Unbelievable,” Charles Bradshaw said during an October 13 tour of ORNL that included the Center for Computational Sciences and EVEREST Powerwall visualization room. “Science fiction.”

|

|

| Bradwhaw |

Bradshaw is in a position to know how far the field has come. From spring 1954 to summer 1956, he worked for ORNL’s computing organization, then known as the Mathematics Panel. There, he solved nuclear criticality problems on the Laboratory’s ORACLE computer.

ORACLE, which was for a time the fastest computer in the world, was built with a capacity of 1,024 “words” of 40 bits apiece, which were stored on a series of cathode ray “Williams” tubes. Although it was a significant advance, Bradshaw noted, ORACLE lacked many of the tools computer programmers now take for granted—among them modern programming languages.

“Programming then was programming one operation at a time,” he said. “When I was here, we didn’t have FORTRAN; we programmed almost in machine language.”

Bradshaw’s tour of the NCCS included a close-up look at the center’s high-performance computing systems, among them the Cray XT3 system known as Jaguar, which can perform more than 50 trillion calculations in a single second. He also learned of plans by the center to add a supercomputer in 2008 that will be capable of 1,000 trillion calculations each second.

“I still don’t quite believe it,” he said, “unless I trust this fellow (the center’s Bobby Whitten, who led Bradshaw’s tour). We see today the small computers that will fit on your desk, and you realize that one of those can do 10,000 times as much as the ORACLE could do.”

Bradshaw also viewed several demonstrations on the EVEREST Powerwall, a 30-foot-wide, 8-foot-tall tiled display that can show 35 million pixels of information. It, too, would have been alien to the researchers working at ORNL in the 1950s.

“Our output was a bunch of paper tape, and that’s all,” Bradshaw explained. “We’d put it on punch paper tape, and you’d have to take it over to the teletype writer and print it up. Debugging was done at the console from about midnight to four in the morning.”

After leaving ORNL, Bradshaw went on to work with rocket science champion Wernher von Braun at the Marshall Space Flight Center in Huntsville, Ala. He eventually retired from Vanderbilt University as director of computing.

Bradshaw now lives in Lebanon, Tenn., and has recently finished a book, titled Rockets, Reactors, and Computers, which argues that these developments are the most important of the 20th century. He was in Oak Ridge at the invitation of his daughter-in-law Janet Bradshaw, who works at the Y-12 National Security Complex.

“I’ve been wanting to get back to Oak Ridge to see some of these phenomenal things for 30 years, and finally she got me and my wife a trip up here,” he explained.—Leo Williams ![]()

‘ORICLE fall-winter

signup through January 3

‘ORICLE fall-winter

signup through January 3

The Oak Ridge Institute for Continued Learning’s early registration for the

winter-spring 2007 term runs through January 3, with a rich and varied slate of courses and trips.

Activities and courses though the Roane State Community College noncredit curriculum include historical facts about Abraham Lincoln including the music he enjoyed, a trip to the site of the notorious Andersonville prison in Georgia, the latest in radiation oncology at Methodist Medical Center, a tulip tour of the Armstrong-Lockett house and gardens and a trip to the Bristol Motor Speedway.

Residents of Oak Ridge and the surrounding area from all backgrounds and education levels are welcome to join ORICL. Call (865) 481-8222 or visit discoveret.org/oricl for more information and to register.

Bill Cabage, editor, ORNL, 865/574-4399 (cabagewh@ornl.gov)

Deborah Barnes, associate editor, 865/576-0470 (barnesds@ornl.gov)

ORNL office: P.O. Box 2008, Oak Ridge, TN 37831-6146, Building 4500-N, Room K-238, MS 6266

News Deadlines

DOE inspector general hotline: 1-800-541-1625

[an error occurred while processing this directive] [an error occurred while processing this directive]