Research - Watching Nanotubes Grow

in situ Measurements of Nanotube Growth by Chemical Vapor Deposition

How fast do carbon nanotubes grow? Why does growth stop? Can growth be stopped, then restarted?

Very few direct measurements have been made to try and answer these important questions. The problem normally is that nanotubes grow in random directions, so it is difficult to determine their lengths. However, when nanotubes grow in crowded arrays, their lengths are easier to estimate.

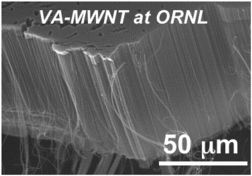

Vertically-Aligned Multiwall Carbon Nanotube (VA-MWNT) Arrays

Vertically-aligned

multiwall carbon nanotube (VA-MWNT) arrays are grown from metal catalyst films

at ORNL by thermal CVD for use in composites.

Mixed with the MWNT are single-wall carbon nanotubes (SWNT) at most processing

temperatures. Research is concentrating upon understanding what stops nanotube

growth, how growth can be continued to long lengths (millimeters and longer),

and methods to increase the growth rate so that long, continuous nanotube

fibers can be produced for composites.

Vertically-aligned

multiwall carbon nanotube (VA-MWNT) arrays are grown from metal catalyst films

at ORNL by thermal CVD for use in composites.

Mixed with the MWNT are single-wall carbon nanotubes (SWNT) at most processing

temperatures. Research is concentrating upon understanding what stops nanotube

growth, how growth can be continued to long lengths (millimeters and longer),

and methods to increase the growth rate so that long, continuous nanotube

fibers can be produced for composites.

Vertically-aligned arrays of multiwall carbon nanotubes (VAA-MWNT) grow in a concerted fashion, preserving a relatively smooth top surface of the array as they grow. This permits in situ measurements of their growth kinetics.

Appl. Phys. Lett. 83, 1851 (2003). Download PDF file (320 kB)

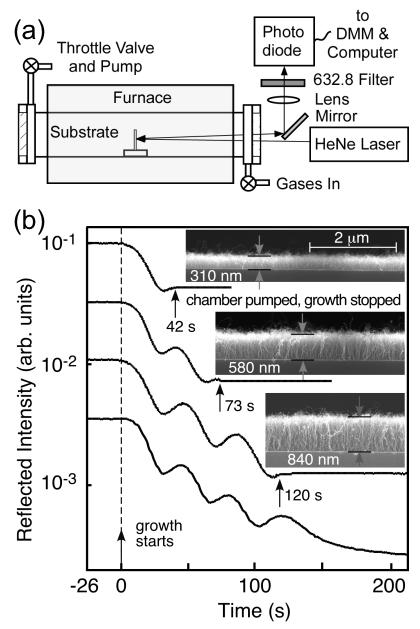

In situ reflectivity technique

As shown below, a helium-neon laser is used to illuminate the substrate at normal incidence, which is placed vertically in the center of the tube furnace. The reflected beam returns through the front window of the furnace, and is directed onto a photodiode which records its intensity.

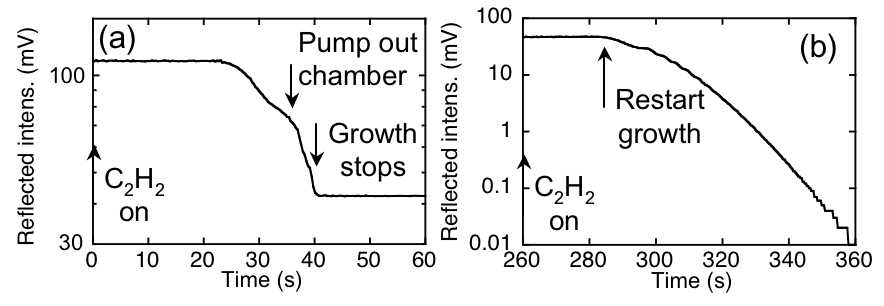

As shown above on a logarithmic scale, the reflected intensity drops rapidly as the nanotubes attenuate the beam. However, for roughly the first 10 microns of growth, the emerging array is porous enough to permit some of the laser beam to reach the silicon substrate, reflect, and return to the detector. In addition, there is a reflection from the top surface of the array. These two reflections constructively and destructively interfere to form a series of Fabry-Perot fringes which can be used to estimate the height of the nanotube array as it grows. By pumping out the chamber quickly at different maxima and minima of these oscillations, a calibration between length and fringe number is obtained, as shown above.

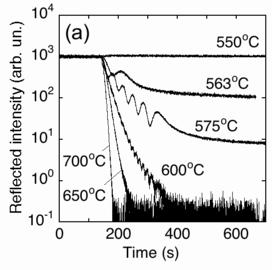

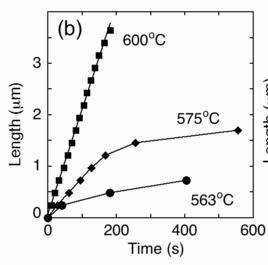

Growth kinetics measurements

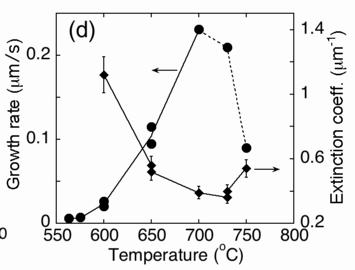

Then, each fringe can be used as a length marker, and a temporal plot can be made as shown above. As can be seen, the rate of growth is then obtained by the slope of the length-time plot, and immediately one can see how growth in some cases slows down or even stops after a good start. Such information is crucial as input for models to understand why growth stops, and how to keep nanotubes growing to longer and longer lengths. By plotting the maximum growth rate vs. growth temperature, one obtains an optimal temperature for fast growth.

However, one must be careful. The above calibrations revealed that the optical properties of the arrays change with temperature, as can be seen by the variation in the extinction coefficient in (d) above. One reason for this could be changing porosity of the nanotube arrays, however it is more likely the changing number of walls in the nanotubes within the array which yield the lower extinction coefficients.

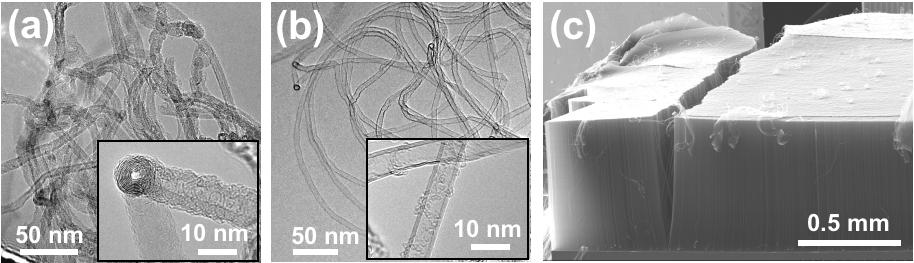

Images of nanotubes grown at different processing temperatures

Nanotubes grown at lower temperatures (575-600 C) shown in (a) have more walls than those grown at higher temperatures (700-730 C) shown in (b). Both are hollow along their length, with wall defects but without the "bamboo" morphology sometimes observed in other growth techniques. Nanotubes grown at the highest growth rates continue to grow to long lengths (as shown in (c)), and are predominantly double-walled with large inner diameters.

Restarting nanotube growth

Can nanotube growth be stopped, and then restarted? It depends on the activity of the catalyst nanoparticle responsible for the nanotube growth, and this activity may degrade with time. Such questions are easily answered experimentally using the in situ reflectivity technique. As demonstrated below, growth can be stopped by pumping out the growth gas (acetylene/hydrogen/argon mixture). The reflectivity holds constant. Then the growth gas is reintroduced after 240 seconds. Growth begins again, as seen by the continued drop in the reflectivity signal. The reflectivity technique is important to study how to restart growth from catalyst nanoparticles which have become overcoated or poisoned after growth terminates naturally.

More details?

Please see Appl. Phys. Lett. 83, 1851 (2003). Download PDF file (320 kB)