- Number 297 |

- October 12, 2009

NETL identifies refractory compositions as having potential for slagging gasifier liners

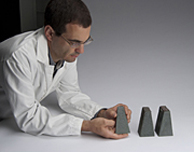

Researcher Hugh Thomas

examines NETL refractory test

bricks being developed for

improved service life in gasifiers.

The Department of Energy’s National Energy Technology Laboratory (NETL) is developing refractory material with improved performance that could replace the high chrome oxide materials currently used as liner materials in high-temperature slagging gasifiers. In cooperation with refractory manufacturers and gasifier users, NETL researchers have identified five compositions through laboratory testing out of 14 thought to have potential for meeting gasifier performance criteria. One of the five has been identified for initial performance evaluation in a commercial slagging gasfier under gasification conditions. The lack of reliable and long term refractory linings is one of the top research needs in gasifiers, with on-line gasifier availability goals of industry being 85-95% for utility applications and greater than 95% in applications such as chemical feedstock production. Lack of achieving these goals has limited widespread acceptance and use of gasification technology.

Gasification is used by industry to convert low cost carbon into materials for producing electricity and chemical products such as fertilizer, plastics, and Fischer-Tropsch liquids. It could play a key role in defining the nation’s long-term energy security in both power and liquid fuels, and is considered a leading candidate for hydrogen production. The process of gasification occurs in a high-temperature, high-pressure chemical reaction vessel that converts carbon and water in a low-oxygen environment into carbon monoxide and hydrogen-feedstock materials for other processes.

Slag originating from mineral impurities in the carbon feedstock is of the most concern to slagging gasifier operation. It can be 10 percent or more of the feedstock’s weight. Gasifiers capable of processing 1400 tons or more per day of carbon can generate 100 tons per day of liquid slag. The liquid slag wears away the internal lining (refractory) of the gasifier vessel by two means, chemical dissolution and spalling. The service life of the refractory lining is between 3 and 30 months, depending on where in the gasifier the lining failure is located. Lining failure is expensive, both in terms of material replacement costs (as high as $1,000,000), and in lost production due to gasifier shutdown. The time to replace a lining can range from about five days for small repairs, to as long as 25 for a complete rebuild.

Submitted by DOE's National Energy Technology Laboratory