- Number 384 |

- March 18, 2013

Collaboration puts natural gas on the road

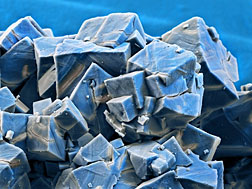

Improved metal-organic frameworks.

DOE''s Savannah River National Laboratory, in partnership with Ford Motor Company, the University of California-Berkeley, and BASF, has research underway to explore an innovative low-pressure material-based natural gas fuel system for automobiles and other light vehicles.

The Advanced Research Projects Agency-Energy (ARPA-E) funded project is looking to accelerate the use of natural gas in vehicles by reducing the pressure of on-board tanks with a proposed technology using adsorbed natural gas (ANG). The project will use high surface area materials within a heat exchange system to increase the natural gas density far beyond that which can be achieved at similar pressures.

The first focus of the project is to develop improved metal-organic frameworks to adsorb the natural gas at high densities. Building on SRNL’s extensive knowledge of hydrogen storage materials and systems, researchers here are responsible for designing and testing high performance fuel systems to use these next-generation metal-organic frameworks. This innovative research has the potential to lower the cost of storage tanks and compressors at the fueling station, resulting in increased use of natural gas vehicles.

Today’s natural gas vehicle technologies require tanks that can withstand high pressures, are often cumbersome, and are either too large or too expensive to be suitable for light duty passenger vehicles. SRNL’s research and ARPA-E’s new projects are focused on removing these barriers, which will help encourage the wider use of natural gas cars and trucks.

Through ARPA-E, the Department of Energy’s new program, titled Methane Opportunities for Vehicular Energy - or “MOVE” – aims to engineer light-weight, affordable natural gas tanks for vehicles and develop natural gas compressors that can efficiently fuel a natural gas vehicle at home.

Compressed natural gas (CNG) is composed primarily of methane. It is typically stored and distributed in expensive pressure vessels at 3,000 to 3,600 psi. About 85 percent of the CNG used in the United States is produced domestically. CNG is used in traditional gasoline internal combustion engines that have been modified for its use. The benefits of CNG are numerous; it is a nontoxic, clean-burning fuel and significantly reduces carbon monoxide, carbon dioxide and nitrogen oxides compared to gasoline. According to the U.S. Environmental Protection Agency, use of CNG can result in 30-40% less greenhouse gas emissions.[Will Callicott, 803.725.3786,

will.callicott@srnl.doe.gov]