- Number 450 |

- October 19, 2015

New equation bolsters multiphase modeling code

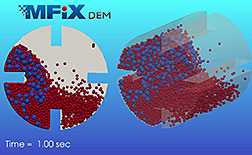

This simulation demonstrates how a rotary

drum is used to mix different types of solid

particles.

While designing models for the Multiphase Flow with Interphase Exchanges (MFiX) code, one of the National Energy Technology Laboratory’s most robust computational tools, Physical Research Scientist Jordan Musser realized that an important component of energy system behavior was not accurately accounted for in the existing code. In energy systems, it is common for more than one phase of matter to interact with another, a phenomenon known as multiphase flow. For instance, during combustion and gasification, coal particles interact with gases, creating a gas-solid.

Within these flows, the constituents may change phases during reactions, releasing heat energy that researchers must carefully account for as they build models to predict how energy systems will behave. More accuracy provides greater confidence in these tools which may be used to reduce scale-up time and decrease capital investments, leading to cheaper, more efficient systems that will be deployed more rapidly.

Musser explained that it is important to accurately quantify the heat energy released during a phase transition. “Reaction rates are strongly based upon the temperature of the reacting fields,” he said. “So if a reaction occurs and the heat transfer is not allocated correctly among these two phases, the reaction in the model may proceed more slowly or more quickly than researchers anticipated.”

Either way, the characteristics of a real-world product—syngas quality in the case of gasification—could be different than what the model predicted. If the temperature is too high, for instance, gasification reactions may be hampered, resulting in a different than expected mix of carbon monoxide and hydrogen. These results could mislead design engineers working to optimize the operation of a gasifier, reducing the usefulness and effectiveness of computational tools.

Musser set out to improve heat transfer accounting in reactive flow modeling. He designed an equation to account for the energy released during mass transfer between phases. This code was then incorporated into the MFiX code and verified by physically capturing data that are measured experimentally on the evaporation and condensation of a liquid droplet. When the physical data aligned with the model’s prediction, the researchers verified that the new model was much more physically accurate than the old model.

Musser published his research in Chemical Engineering Science in an article titled “Constitutive Equation for Heat Transfer Caused by Mass Transfer.” News of Musser’s improved model quickly spread, and soon a commercial software code, Barracuda, had implemented the NETL mathematical model to increase its ability to accurately account for heat transfer.[Linda Morton, 304.285.4543,

Linda.morton@netl.doe.gov]