- Number 403 |

- December 16, 2013

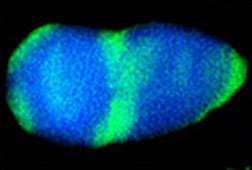

The character of a cathode

Scientists obtained a definitive view of an

LMNO cathode. The X-ray energy-dispersive

spectroscopy map shown here indicates

the distribution of manganese (blue) and

nickel (green).

Scientists at DOE’s Pacific Northwest National Laboratory, FEI Company, and DOE’s Argonne National Laboratory obtained a definitive view of a pristine cathode made of lithium, nickel, manganese, and oxygen. Controversy has encircled this cathode, abbreviated LMNO. Some state it’s a solid solution; others, a composite. The team, using a suite of tools, determined the material is actually a composite with tightly integrated phases. Further, they found the surface contains high levels of nickel and low levels of oxygen and electron-rich manganese.

“If we want to improve the cycle life and capacity of the layered cathode, we must have this type of clarity around the atomic structure,” said Dr. Nigel Browning, the Chief Science Officer of PNNL’s Chemical Imaging Initiative and a microscopy expert who worked on the study.

This cathode could play a role in replacing gasoline-powered cars with electric-powered ones, which ultimately could drop U.S. oil imports by ~60%, and reduce harmful emissions as much as 45%, depending on the technological mix used. The key is long-lasting, energy-dense batteries, yet innovative LMNO cathodes suffer from voltage fading and capacity issues linked to the cathode’s structure during charging and discharging. The team’s research provides the basis for needed discoveries to overcome these issues.

“The ever-growing energy demands of information and transportation rely on lithium-ion batteries for power storage, because of their relatively high energy density and design flexibility. We need better batteries, and we need them now,” said Dr. Chongmin Wang, chemical imaging expert at PNNL and lead investigator on this study.

The team used aberration-corrected scanning transmission electron microscopy, X-ray energy-dispersive spectroscopy, electron energy loss spectroscopy, and complementary multi-slice image simulation to probe LMNO nanoparticles. The instruments were located at the Environmental Molecular Sciences Laboratory and National Center for Electron Microscopy.

The team made several discoveries. The surface with certain structural characteristics is prone to contain a higher concentration of nickel atoms than the particle’s core. Manganese atoms are more prevalent at the core than the surface. Oxygen vacancies on the particle’s surface result in manganese atoms having a valence state or electron configuration of +2.2 on the surface, while the manganese at the particle’s core is +4.0.

“This finding indicates a big variation in the local stoichiometry,” said Dr. Jun Liu, a materials expert who worked on this study and who is also Director of PNNL’s Energy Processes and Materials Division.

Finally, each particle contains both of the material’s parent phases. The lattice parameter and crystal structure similarity of the layered LiMO2 phase and the layered Li2MO3 phase allow the structural integration. Here, M represents the metal ion.

“This detailed characterization allowed us to gain a more complete picture of the material,” said Wang. “Clarification of the material’s structure — nanoscale phase separation, cation ordering, and oxygen vacancy formation — will undoubtedly shine a new light on probing how the material behaves during battery performance and will inspire us to improve its functionality via controlled synthesis.”[Kristin Manke, 509.372.6011,

kristin.manke@pnnl.gov]